A method for separating isoamyl alcohol and isoamyl acetate

A technology of isoamyl acetate and isoamyl alcohol, applied in chemical instruments and methods, preparation of carboxylate, preparation of organic compounds, etc., can solve problems such as difficulty in separation and insufficient purity, and achieve the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

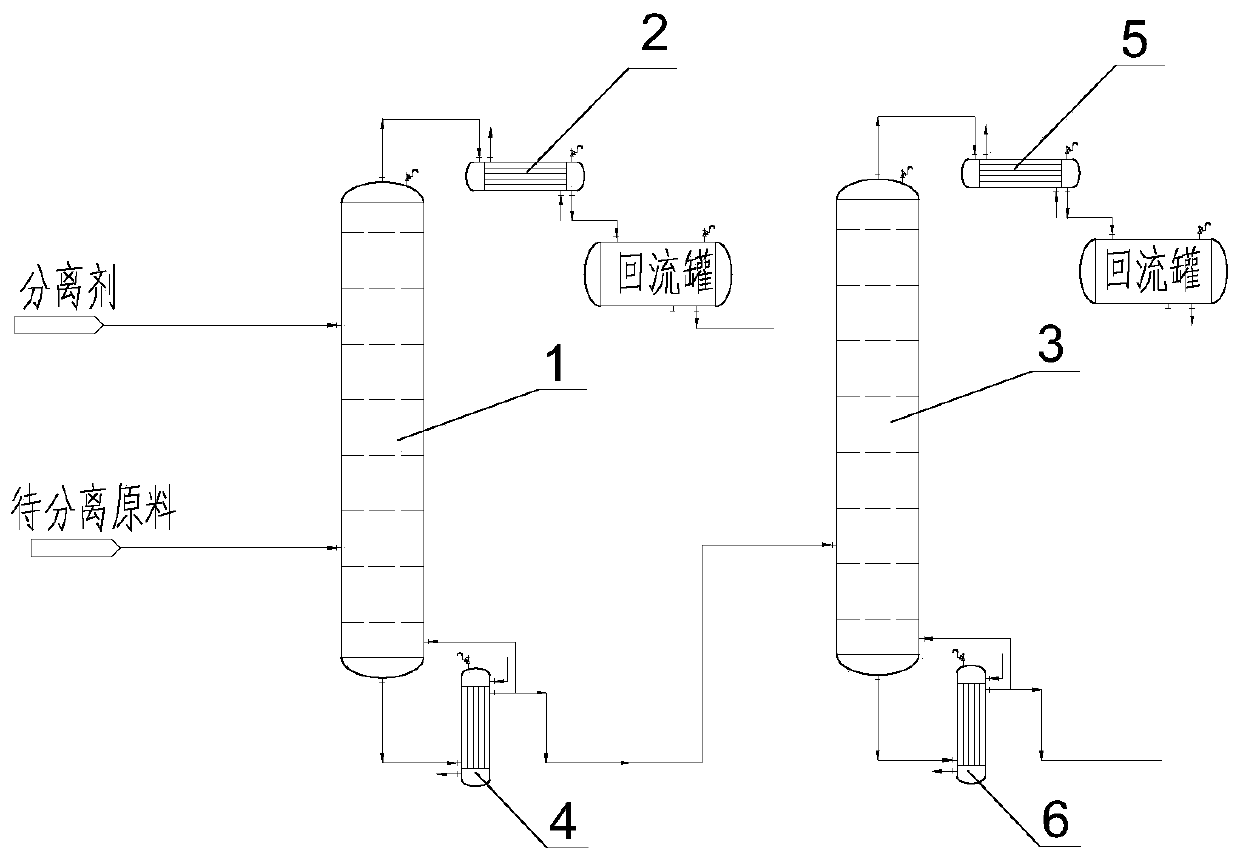

[0033] A method for separating isoamyl alcohol and isoamyl acetate by continuous azeotropic distillation, comprising the following steps:

[0034] (1) Adopting the first rectifying tower 1 whose total number of theoretical plates is 33, adding the separation aid benzyl chloride from the 12th theoretical plate on the top of the tower, adding the raw materials to be separated from the 27th theoretical plate, and carrying out the extraction process Distillation, when the vapor-liquid balance is reached, the steam in the tower top is condensed by the first condenser 2, and the liquid obtained by collecting the condensed reflux is used as the production liquid, which is isoamyl alcohol;

[0035] Among them, the mass ratio of isoamyl alcohol and isoamyl acetate in the raw material to be separated is 68:32, the processing capacity of the raw material to be separated is 100Kg / hr, and the feeding condition is normal pressure bubble point feeding; the addition of the separation aid benzy...

Embodiment 2

[0042] A method for separating isoamyl alcohol and isoamyl acetate by continuous azeotropic distillation, comprising the following steps:

[0043] (1) Adopting the first rectifying tower 1 whose total number of theoretical plates is 33, adding the separation aid benzyl chloride from the 12th theoretical plate on the top of the tower, adding the raw materials to be separated from the 27th theoretical plate, and carrying out the extraction process Distillation, when the vapor-liquid balance is reached, the steam in the tower top is condensed by the first condenser 2, and the liquid obtained by collecting the condensed reflux is used as the production liquid, which is isoamyl alcohol;

[0044] Wherein, the mass ratio of isoamyl alcohol and isoamyl acetate in the raw material to be separated is 1:0.1, the processing capacity of the raw material to be separated is 100Kg / hr, and the feeding condition is normal pressure bubble point feeding; the addition of the separating agent benzyl...

Embodiment 3

[0051] A method for separating isoamyl alcohol and isoamyl acetate by continuous azeotropic distillation, comprising the following steps:

[0052] (1) Adopting the first rectifying tower 1 whose total number of theoretical plates is 33, adding the separation aid benzyl chloride from the 12th theoretical plate on the top of the tower, adding the raw materials to be separated from the 27th theoretical plate, and carrying out the extraction process Distillation, when the vapor-liquid balance is reached, the steam in the tower top is condensed by the first condenser 2, and the liquid obtained by collecting the condensed reflux is used as the production liquid, which is isoamyl alcohol;

[0053] Wherein, the mass ratio of isoamyl alcohol and isoamyl acetate in the raw material to be separated is 1:10, the processing capacity of the raw material to be separated is 100Kg / hr, and the feeding condition is normal pressure bubble point feeding; the addition of the separating agent benzyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com