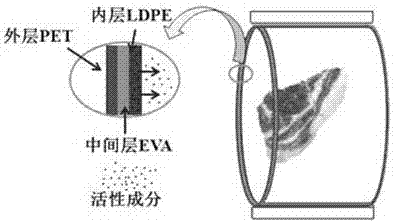

Three-layer composite fresh-keeping film, and preparation method and application thereof

A technology of preservative film and layer compounding, which is applied in the field of packaging materials, can solve the problems that the preservation effect of the preservative film cannot be guaranteed, and the preservation effect cannot be guaranteed, and achieve the effects of maintaining the original flavor and nutritional value, inhibiting the loss of juice, and delaying growth and reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] (1) The active ingredients chitosan, tea polyphenols, ginkgo biloba extract, wisteria flower extract, sage extract and LDPE resin (dried in an oven at 60°C in advance) were mixed thoroughly and evenly stirred. The twin-screw extruder is heated, sheared, extruded, and pelletized to prepare modified LDPE resin;

[0069] The weight ratio of chitosan, tea polyphenols, ginkgo biloba extract, wisteria flower extract, and sage extract is 1:1:1:1:1; the total weight of active ingredients accounts for LDPE of the inner film 1%;

[0070] The extrusion conditions of the twin-screw extruder are as follows: among the 7 heating zones of the extruder, the heating temperature of Zone 1 is 165 °C, the heating temperature of Zone 2 is 170 °C, the heating temperature of Zone 3 is 175 °C, and the heating temperature of Zone 4 is 180 ℃, the heating temperature of zone 5 is 180 ℃, the heating temperature of zone 6 is 175 ℃, and the heating temperature of zone 7 is 170 ℃;

[0071] The screw...

Embodiment 2

[0077] (1) The active ingredients chitosan, tea polyphenols, ginkgo biloba extract, wisteria flower extract, sage extract and LDPE resin (dried in a 60°C oven in advance) were fully mixed and stirred evenly, and the The twin-screw extruder is heated, sheared, extruded, and pelletized to prepare modified LDPE resin;

[0078] The weight ratio of chitosan, tea polyphenols, ginkgo biloba extract, wisteria flower extract, and sage extract is 3:1:5:5:1; the total weight of active ingredients accounts for 5% of the total weight of LDPE resin The condition of twin-screw extrusion is the same as in Example 1 (the condition of twin-screw extrusion in Example 3 is also the same as in Example 1);

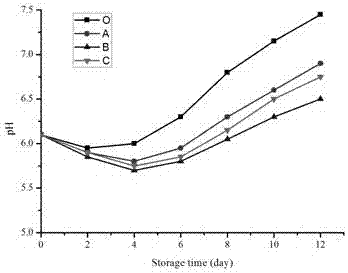

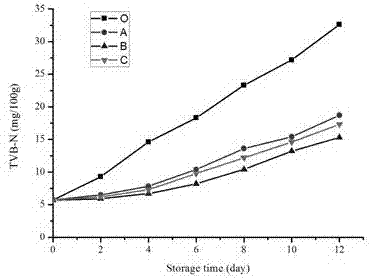

[0079] (2) Then the PET resin, EVA resin and the prepared modified LDPE resin were passed through a multi-layer co-casting device to prepare a three-layer composite mutton cling film B. Tested by the gas permeation instrument, the oxygen transmission rate of the three-layer composite mutton pl...

Embodiment 3

[0083] (1) The active ingredients chitosan, tea polyphenols, ginkgo biloba extract, wisteria flower extract, sage extract and LDPE resin (dried in a 60°C oven in advance) were fully mixed and stirred evenly, and the The twin-screw extruder is heated, sheared, extruded, and pelletized to prepare modified LDPE resin;

[0084] The weight ratio of chitosan, tea polyphenols, ginkgo biloba extract, wisteria flower extract, and sage extract is 3:1:5:5:1 in sequence;

[0085] The total weight of active components accounts for 3% of the total weight of LDPE resin; (the conditions of twin-screw extrusion in embodiment 3 are also the same as embodiment 1);

[0086] (2) Then PET resin, EVA resin and the prepared modified LDPE resin were passed through a multi-layer co-casting device to prepare a three-layer composite mutton cling film C. Tested by the gas permeation instrument, the oxygen transmission rate of the three-layer composite mutton plastic wrap C is 8.80±0.16e -2 (Cm 3 / m 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com