Safe and environmentally-friendly building interior decoration plate and production method thereof

A safe, environmentally friendly and architectural technology, applied in the field of building materials, can solve the problems of users' health and safety hazards, easy deformation, and weak load-bearing capacity, so as to avoid the spread of fire sources, increase the load-bearing capacity, and increase production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

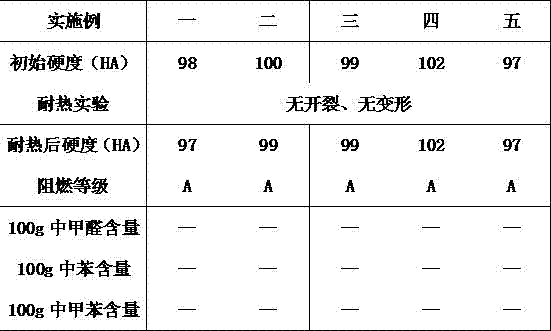

Examples

Embodiment 1

[0017] A safe and environment-friendly building interior trim panel proposed by the present invention comprises the following raw materials in parts by weight: 66 parts of epoxy resin, 38 parts of siloxane, 26 parts of nano silicon dioxide, 16 parts of nano aluminum oxide, and nano mica 12 parts of powder, 1 part of magnesium hydroxide, 2 parts of aluminum hydroxide, 6 parts of sodium polyacrylate, 6 parts of water reducing agent, 1 part of plasticizer, 0.7 parts of catalyst, and 2 parts of crosslinking agent.

[0018] Its preparation method comprises the following steps:

[0019] S1: Put the epoxy resin in a mixer with a temperature of 60°C, heat and melt it, then add corresponding parts by weight of siloxane, crosslinking agent and catalyst, and seal it for 4 hours to obtain a modified epoxy resin solution;

[0020] S2: Add corresponding weight parts of sodium polyacrylate, water reducer and plasticizer to the above-mentioned modified epoxy resin liquid, and knead for 10 min...

Embodiment 2

[0023] A safe and environment-friendly building interior trim panel proposed by the present invention comprises the following raw materials in parts by weight: 72 parts of epoxy resin, 30 parts of siloxane, 34 parts of nano silicon dioxide, 10 parts of nano aluminum oxide, and nano mica 12 parts of powder, 2 parts of magnesium hydroxide, 4 parts of aluminum hydroxide, 8 parts of trimethyl isoamyl alcohol, 2 parts of water reducer, 2 parts of plasticizer, 1 part of catalyst, and 2 parts of crosslinking agent.

[0024] Its preparation method comprises the following steps:

[0025] S1: Put the epoxy resin in a mixer at a temperature of 50°C, heat and melt it, then add corresponding parts by weight of siloxane, cross-linking agent and catalyst, and seal it for 2 hours to obtain a modified epoxy resin solution;

[0026] S2: Add corresponding parts by weight of trimethyl isoamyl alcohol, water reducing agent and plasticizer to the above modified epoxy resin liquid, and knead for 10 ...

Embodiment 3

[0029] A kind of safe and environment-friendly architectural trim panel proposed by the present invention comprises the following raw materials in parts by weight: 72 parts of epoxy resin, 46 parts of siloxane, 28 parts of nano silicon dioxide, 14 parts of nano aluminum oxide, and nano mica 10 parts of powder, 1.5 parts of magnesium hydroxide, 3 parts of aluminum hydroxide, 6 parts of sodium polyacrylate, 2 parts of water reducing agent, 1 part of plasticizer, 0.5 parts of catalyst, and 3 parts of crosslinking agent.

[0030] Its preparation method comprises the following steps:

[0031] S1: Put the epoxy resin in a mixer at a temperature of 55°C, heat and melt it, then add corresponding parts by weight of siloxane, cross-linking agent and catalyst, and seal it for 3 hours to obtain a modified epoxy resin solution;

[0032] S2: Add corresponding weight parts of sodium polyacrylate, water reducer and plasticizer to the above-mentioned modified epoxy resin liquid, and knead for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com