A prefabricated concrete column foot node with outsourcing steel plate and its construction method

A technology of reinforced concrete columns and outer steel plates, applied in the directions of columns, piers, pillars, etc., can solve the problems of high post-earthquake repair cost, difficulty in accurately fixing grouting sleeves, and insufficient restraint of root stirrups, so as to eliminate the need for fixing tooling. , the effect of increased thickness and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

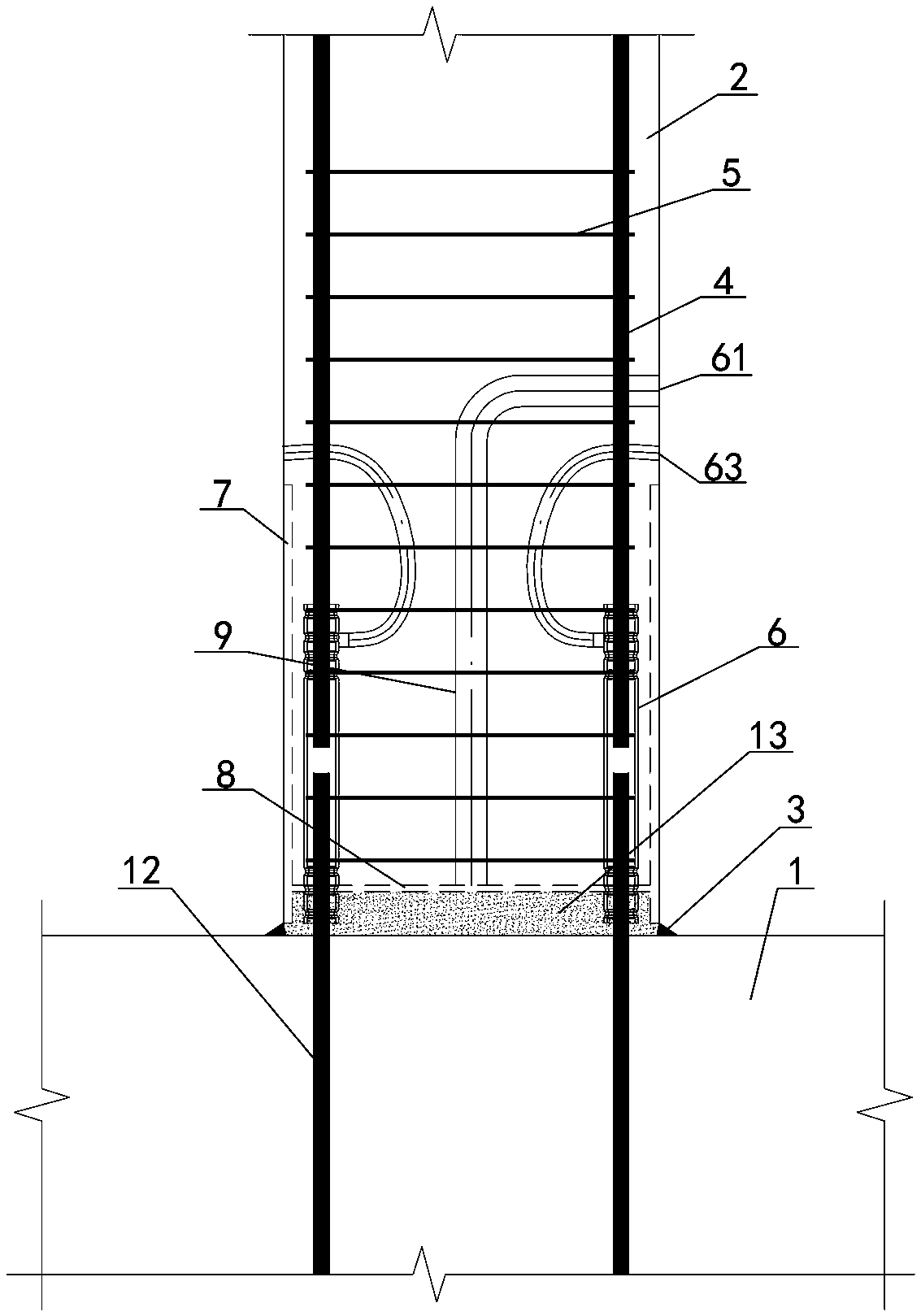

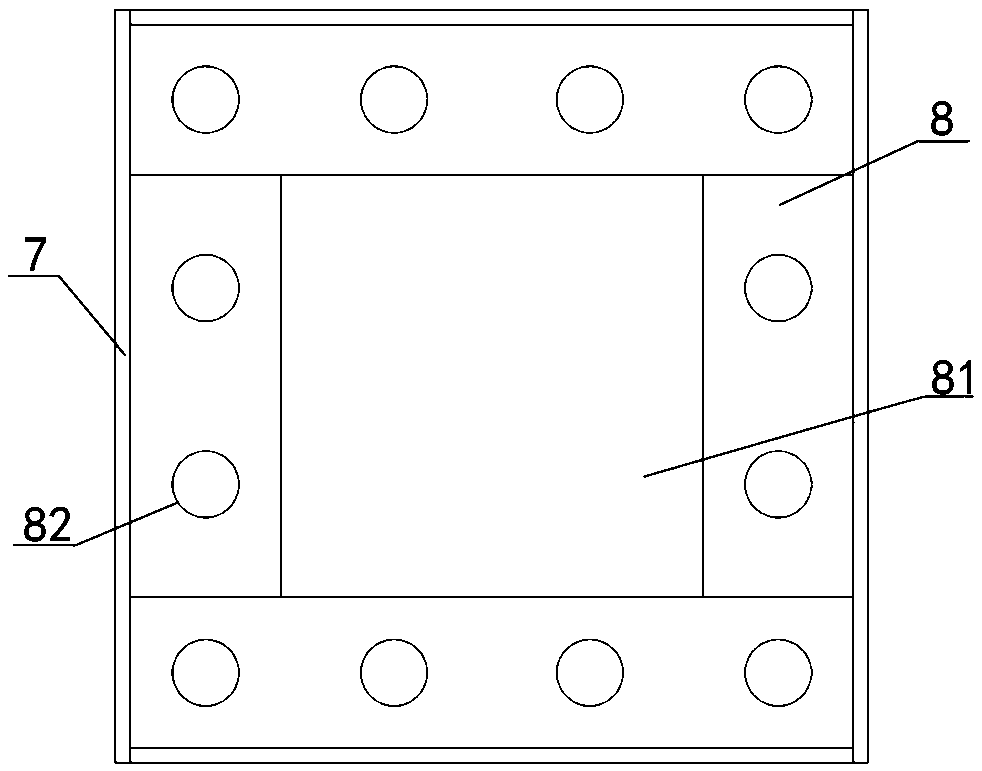

[0042] Embodiment one sees Figure 1-3 As shown, a prefabricated concrete column base node covered with steel plates includes an upper prefabricated reinforced concrete column 2 and a lower reinforced concrete foundation 1 that are spliced vertically. The prefabricated reinforced concrete column 2 is embedded with a Column inner longitudinal bars 4, column inner stirrups 5, and grouting sleeve devices 6 that are evenly distributed around a circle, the reinforced concrete foundation 1 is pre-embedded with foundation anchorage insertion reinforcement bars 12, and the foundation anchorage insertion reinforcement bars 12 and column inner longitudinal reinforcement 4 is connected through the grouting material 13 filled in the grouting sleeve device 6, and the joint between the reinforced concrete foundation 1 and the prefabricated reinforced concrete column 2 is also filled with the grouting material 13.

[0043] The node also includes an outsourcing steel plate cylinder 7 that i...

Embodiment 2

[0051] Embodiment two see Figure 4-5 As shown, the difference from Embodiment 1 is that the grouting sleeve device 6 is a second sleeve with independent grouting holes 62 and independent grouting holes 63, and the grouting material 13 in the second sleeve and the joint cavity is For split casting, the independent grouting hole 62 and the independent grouting hole 63 communicate with the sleeve through corresponding grouting pipes embedded in the column.

Embodiment 3

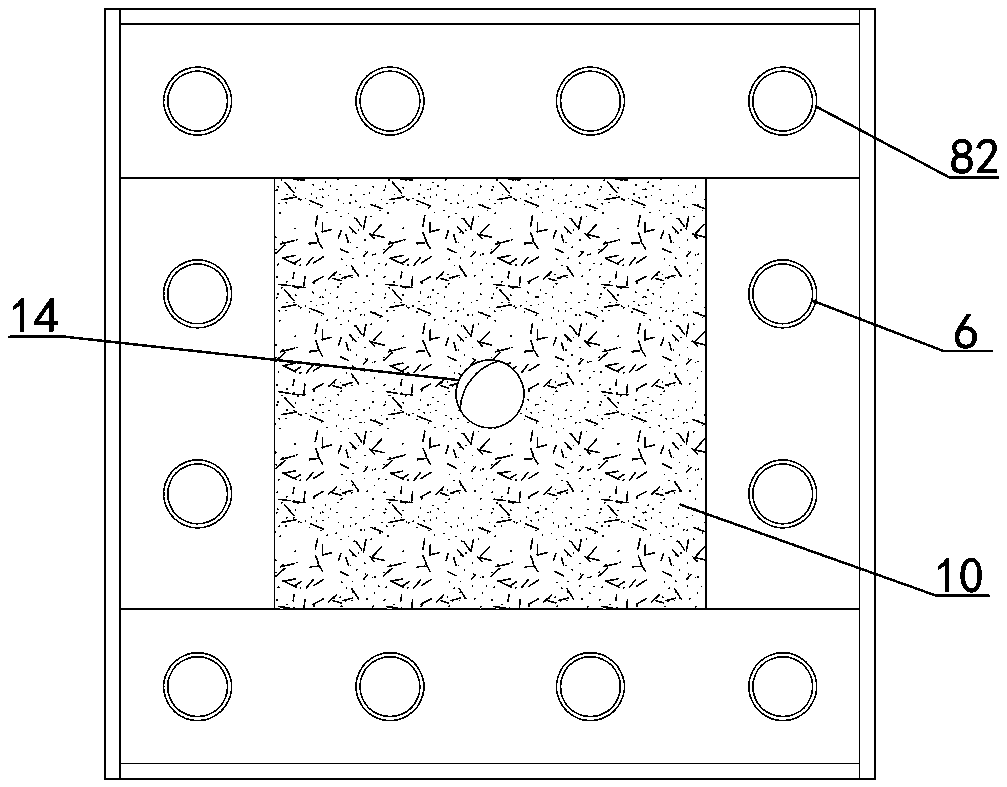

[0052] Embodiment three see Figure 6-7 As shown, the difference from Embodiment 1 is that the grout circulation pipe 9 in the column is a pipe prefabricated integrally with the column, and the bottom of the prefabricated reinforced concrete column 2 shown is integrally prefabricated with a shear key body 11, and the shear key body The surrounding edge of 11 wraps the grouting sleeve device 6 and is flush with the bottom end of the outer steel plate cylinder 7. The middle part of the shear key body 11 is concave in a bucket shape, and the concave bucket shape forms a cavity with the top surface of the foundation. The grouting material 13 is filled, and the middle part of the shear key body 11 is reserved with a grouting hole 14 for the grout circulation pipe in the column.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com