A rapid determination method for total cyanide in cyanide-containing pulp

A rapid determination, cyanide technology, applied in material analysis, measurement device, preparation of test samples by observing the influence of chemical indicators, can solve the problem of no cyanide determination, and achieve convenient operation and short time. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

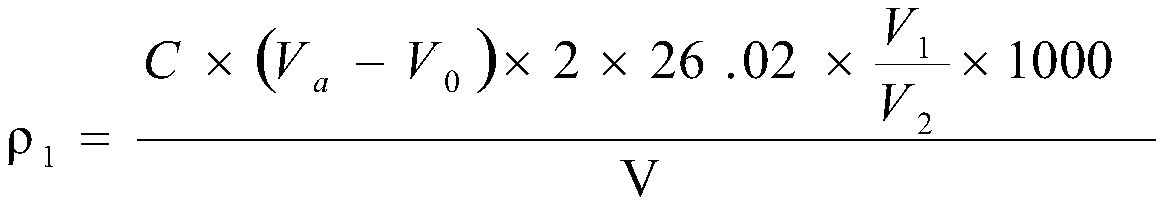

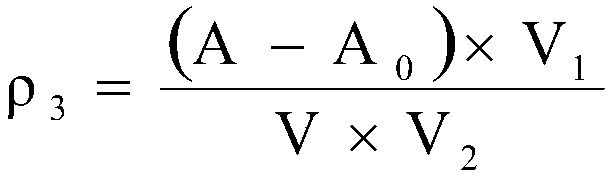

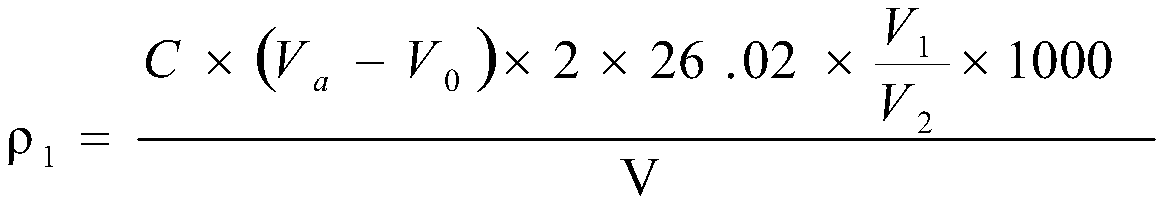

Method used

Image

Examples

Embodiment 1

[0051] Include the following steps:

[0052](1) Use a graduated cylinder to measure a volume V of 200mL ore pulp sample, move it into a distillation flask and add a few glass beads, add 10mL of methanol to the bottle, shake the distillation flask for 2min to mix the sample evenly, add 10mL of CuSO 4 solution and 5mL sodium metabisulfite, shake well, then add 5mL AgNO 3 and 5mL (CH 3 COO) 2 Pb·3H 2 O solution, shake well, connect the distillation device, add 10mL sodium hydroxide solution into the receiving bottle as the absorption liquid, connect the outlet of the condenser tube at the upper end of the distillate conduit, insert the lower end into the absorption liquid of the receiving bottle, check the connection position, Make it tight. When distilling, the lower end of the distillate conduit should be inserted under the liquid surface of the absorption liquid to make the absorption complete;

[0053] (2) Add 15mL of ethylenediaminetetraacetic acid disodium salt EDTA-2Na...

Embodiment 2

[0095] Include the following steps:

[0096] (1) Use a graduated cylinder to measure a volume V of 200mL ore slurry sample, transfer it into a distillation flask and add a few glass beads, add 12.5mL of methanol to the bottle, shake the distillation flask for 2.5min to mix the sample evenly, add 12.5mL of CuSO 4 solution and 7.5mL sodium metabisulfite, shake well, then add 7.5mL AgNO 3 and 7.5mL (CH 3 COO) 2 Pb·3H 2 O solution, shake well, connect the distillation device, add 12.5mL sodium hydroxide solution into the receiving bottle as the absorption liquid, connect the outlet of the condenser tube at the upper end of the distillate conduit, insert the lower end into the absorption liquid of the receiving bottle, and check the connection position , to make it tight, when distilling, the lower end of the distillate conduit should be inserted under the liquid surface of the absorbing liquid to make the absorption complete;

[0097] (2) Add 17.5mL of ethylenediaminetetraacet...

Embodiment 3

[0139] Include the following steps:

[0140] (1) Use a graduated cylinder to measure a volume V of 200mL ore pulp sample, transfer it into a distillation flask and add a few glass beads, add 15mL of methanol to the bottle, shake the distillation flask for 3min to mix the sample evenly, add 15mL of CuSO 4 solution and 10mL sodium metabisulfite, shake well, then add 10mL AgNO 3 and 10mL (CH 3 COO) 2 Pb·3H 2 O solution, shake well, connect the distillation device, add 15mL sodium hydroxide solution into the receiving bottle as the absorption liquid, connect the outlet of the condenser tube at the upper end of the distillate conduit, insert the lower end into the absorption liquid of the receiving bottle, check the connection position, Make it tight. When distilling, the lower end of the distillate conduit should be inserted under the liquid surface of the absorption liquid to make the absorption complete;

[0141] (2) Add 20mL ethylenediaminetetraacetic acid disodium salt sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com