Automatic processing unit monitoring system and method

A processing unit and monitoring system technology, applied in the field of automatic processing unit monitoring system, can solve the problems of low serial communication rate, low system openness, poor reliability, etc., and achieve the integration of human resources, improve transmission efficiency, and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

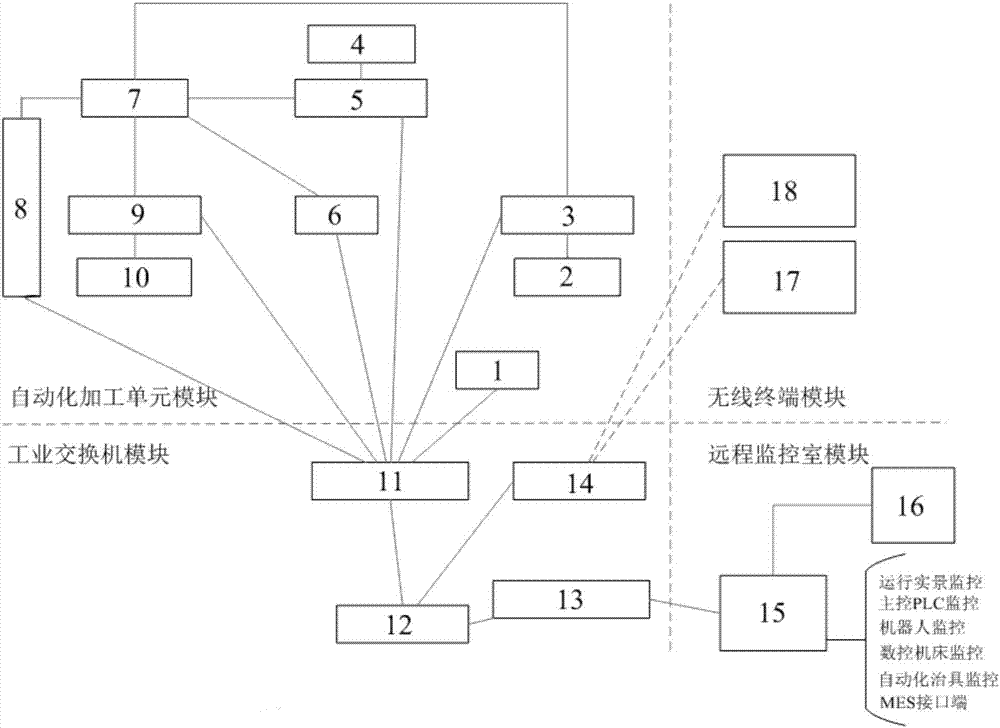

[0032]The invention provides an automatic processing unit monitoring system, which is composed of an automatic processing unit module, an industrial switch module, a remote monitoring room module and a wireless terminal module, and the communication between each module is directly or indirectly realized through the industrial Ethernet. The bottom layer of the monitored equipment is mainly concentrated in the automatic processing module, including the main control PLC, robots, multiple CNC machine tools, and multiple automated fixtures. These devices are directly or indirectly equipped with network card interfaces. When the automation unit is running, the real-time data of these devices are collected, and the data is transmitted to the remote monitoring room module or wireless terminal module through the industrial switch module network.

[0033] see figure 1 , the automatic processing unit monitoring system of the present invention is made up of four parts, is respectively aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com