Fe-N doping porous carbon oxygen reduction catalyst

A porous carbon and catalyst technology, applied in the field of redox electrocatalytic materials, can solve the problems of high price, limited application, shortage of resources, etc., and achieve the effects of low price, good methanol resistance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This example relates to a Fe-N doped porous carbon-oxygen reduction catalyst, which is prepared by the following method:

[0042] 1. Preparation of silk fibroin

[0043]1) Accurately weigh 2g Na 2 CO 3 , dissolved in 400mL distilled water, Na 2 CO 3 The solution was heated to 98°C, and then 4 g of shredded cocoons were put into it for refining, twice for 30 minutes each time; the refined cocoon layer was fully washed with distilled water, and dried naturally to obtain silk fibers.

[0044] 2) Weigh 50g CaCl 2 Dissolve the solid in 100 mL of distilled water, heat to 98° C., add the dried silk fibroin fiber in step 2), and heat for 10 min to obtain a translucent thick silk fibroin crude solution.

[0045] 3) pour the thick solution obtained in step 3) into a cellulose dialysis membrane with a molecular composition of 12000-14000, and dialyze in running water for 3 days to obtain a silk fibroin solution, wherein the concentration of silk fibroin is about 4wt% ;

[0...

Embodiment 2

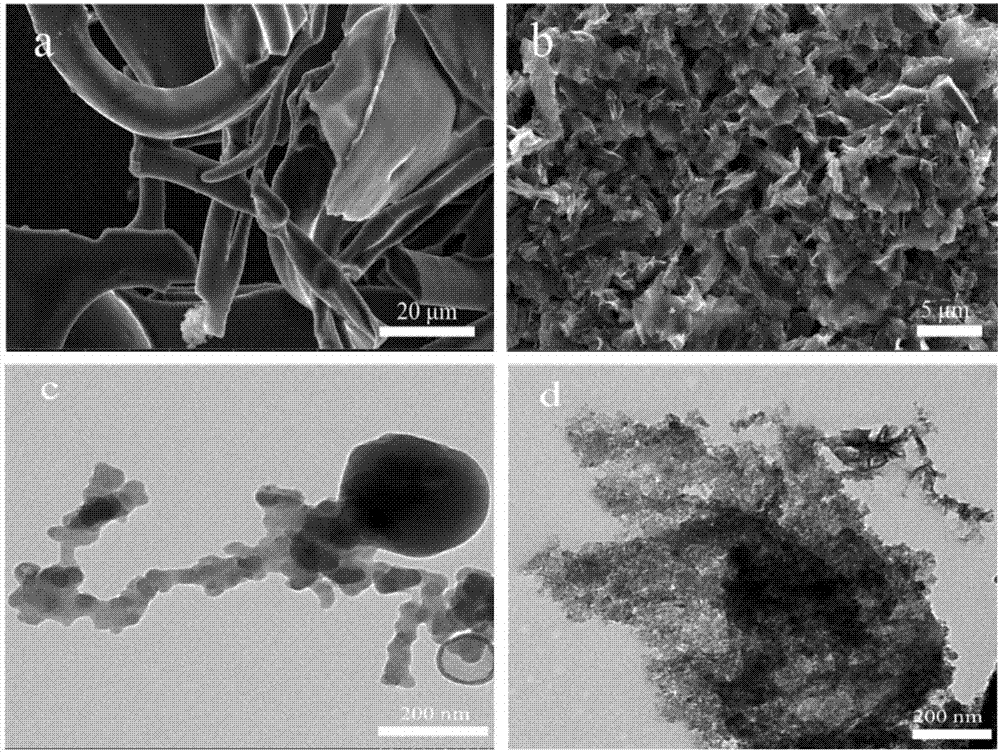

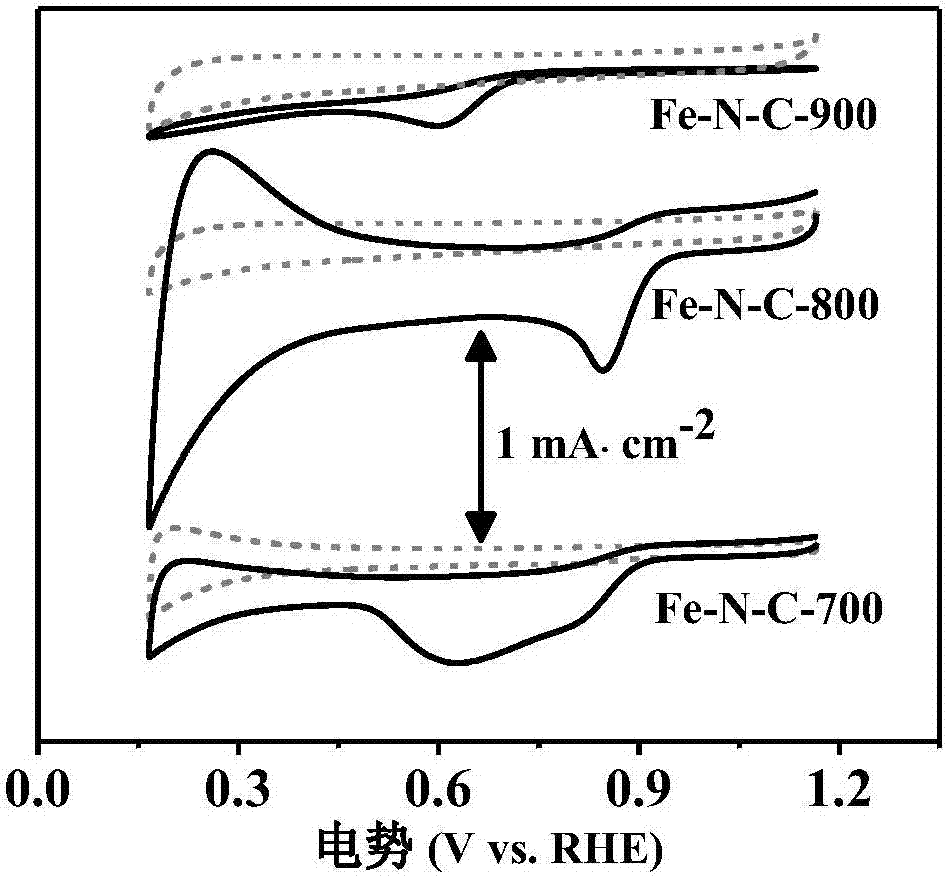

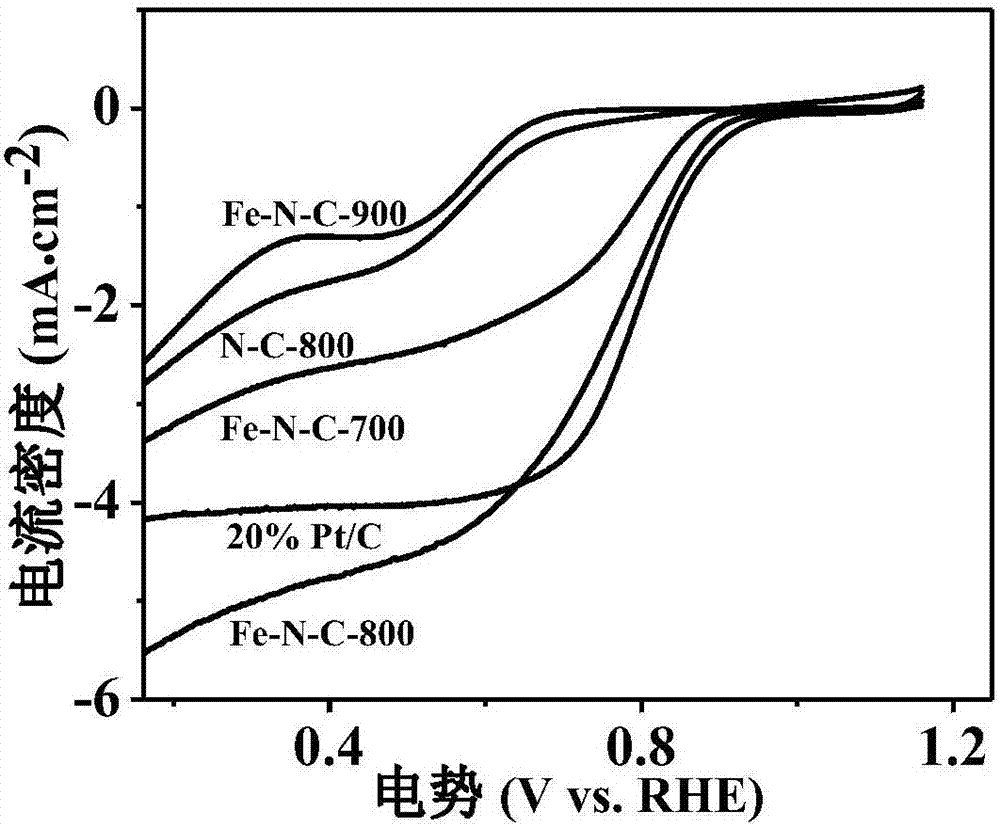

[0052] The experimental procedure is the same as in Example 1, the difference is that during the high-temperature heat treatment, the heating temperature in the tube furnace is controlled to be 700°C, and Fe-N-C-700 is prepared, and the characterization methods (SEM, TEM) are the same as those in Example 1 , electrochemical test method (CV, LSV, i-t) is also the same as embodiment 1.

Embodiment 3

[0054] The experimental procedure is the same as in Example 1, the difference is that during the high-temperature heat treatment, the heating temperature in the tube furnace is controlled to be 900°C to prepare Fe-N-C-900, and the characterization methods (SEM, TEM) are the same as in Example 1 , electrochemical test method (CV, LSV, i-t) is also identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com