Method for superfine grinding of bamboo shoot dietary fibers

A technology of bamboo shoot dietary fiber and dietary fiber, which is applied in the field of ultra-fine pulverization of dietary fiber, can solve problems such as rough taste of dietary fiber, and achieve the effects of increasing functional groups, improving taste and enhancing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Preparation of dietary fiber by compound enzymatic hydrolysis method. Thunder bamboo shoots powder and pure water are mixed evenly at a material-to-liquid ratio of 1:15, cooled after gelatinization at 95°C, and 0.3% α-amylase (adjusted to pH 6.0, 70°C, 1h), 0.45% glucoamylase (adjusted to pH 4 .2, 60°C, 1h) and 0.6% protease (adjust pH to 7.0, 55°C, 2h), then 100°C, 10min inactivate enzyme treatment, wash with water until neutral, dry in an oven at 50°C for later use.

[0025] 2) Pulverization treatment of the dietary fiber of bamboo shoots. Put the prepared dietary fiber of thunder bamboo shoots into a universal pulverizer for ordinary pulverization, and the pulverized dietary fiber is passed through a 100-mesh sieve.

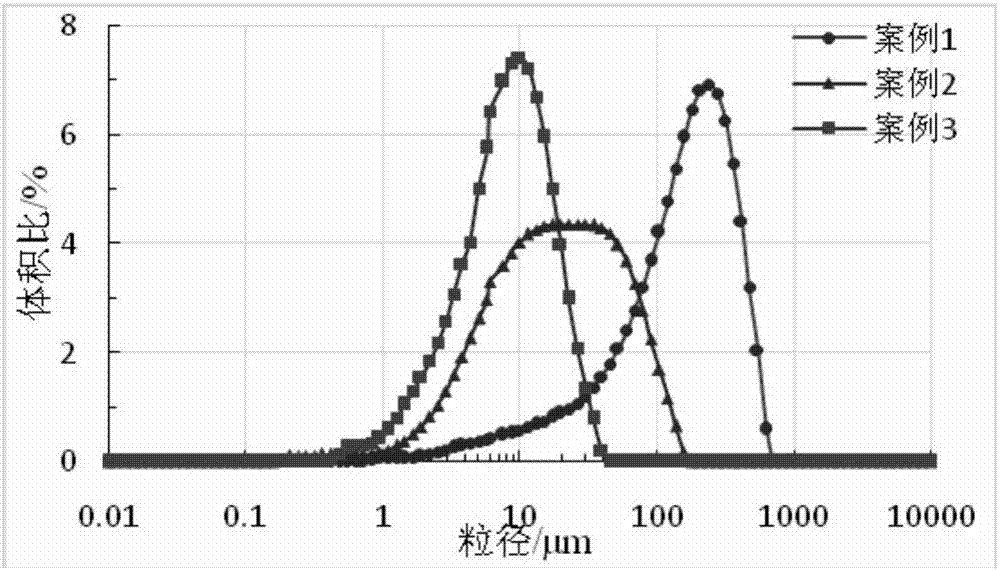

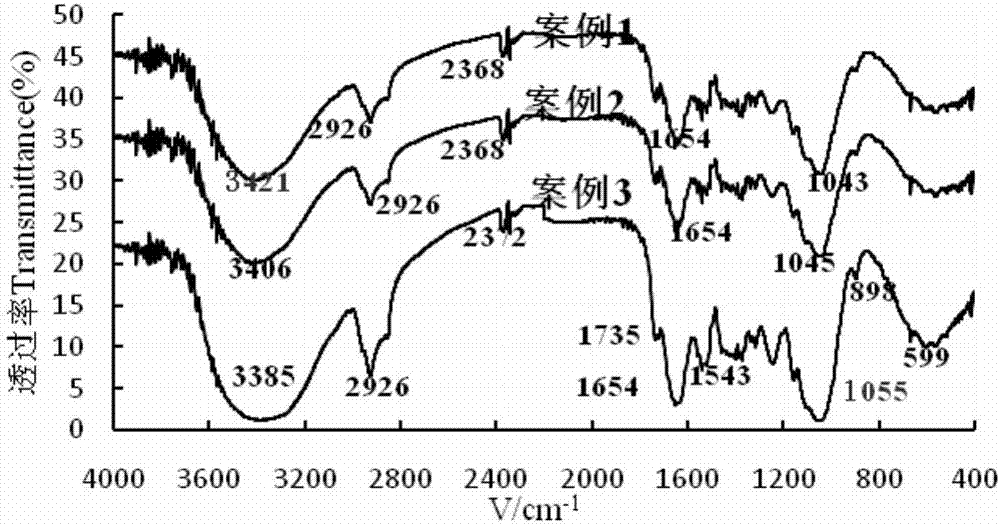

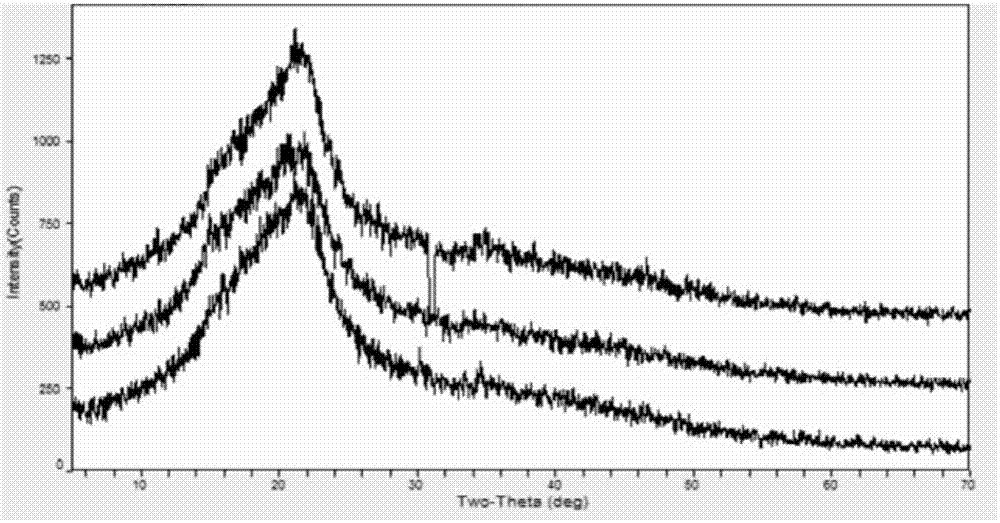

[0026] 3) Characterize the structure of the dietary fiber of the pulverized Lei Bamboo shoots. The structure of dietary fiber was characterized by laser particle size analyzer, Fourier transform infrared spectrometer, X-ray diffraction, simultaneou...

Embodiment 2

[0029] 1) Preparation of dietary fiber by compound enzymatic hydrolysis method. Thunder bamboo shoots powder and pure water are mixed evenly at a material-to-liquid ratio of 1:15, cooled after gelatinization at 95°C, and 0.3% α-amylase (adjusted to pH 6.0, 70°C, 1h), 0.45% glucoamylase (adjusted to pH 4 .2, 60°C, 1h) and 0.6% protease (adjust pH to 7.0, 55°C, 2h), then 100°C, 10min inactivate enzyme treatment, wash with water until neutral, dry in an oven at 50°C for later use.

[0030] 2) Pulverization treatment of the dietary fiber of bamboo shoots. The prepared dietary fiber of thunder bamboo shoots is pulverized with a ZKY-303BS ultrafine pulverizer for about 1 hour, and the size of the airflow is adjusted to classify and collect for later use.

[0031] 3) Characterize the structure of the ultramicronized dietary fiber of Lei Bamboo shoots. The structure of dietary fiber was characterized by laser particle size analyzer, Fourier transform infrared spectrometer, X-ray dif...

Embodiment 3

[0034] 1) Preparation of dietary fiber by compound enzymatic hydrolysis method. Thunder bamboo shoots powder and pure water are mixed evenly at a material-to-liquid ratio of 1:15, cooled after gelatinization at 95°C, and 0.3% α-amylase (adjusted to pH 6.0, 70°C, 1h), 0.45% glucoamylase (adjusted to pH 4 .2, 60°C, 1h) and 0.6% protease (adjust pH to 7.0, 55°C, 2h), then 100°C, 10min to inactivate the enzyme, wash with water until neutral, and dry in an oven at 50°C for later use.

[0035] 2) Pulverization treatment of the dietary fiber of bamboo shoots. Use Micron Jet MillPilot airflow milling ultrafine pulverization process (parameters pulverization pressure 10bar, pulverization speed 8r / min) with the prepared Lei bamboo shoots dietary fiber, time is about 1 hour, airflow classification treatment, different collectors collect the dietary fiber of different particle sizes .

[0036] 3) Characterize the structure of the ultramicronized dietary fiber of Lei Bamboo shoots. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com