AAO process water treatment equipment

A technology for treatment equipment and process water, applied in the field of water treatment, can solve the problems of low quality of effluent water, reduction of suspended solids, low denitrification and phosphorus removal efficiency, etc., to achieve the effect of improving the effect, prolonging the reaction period and improving the removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

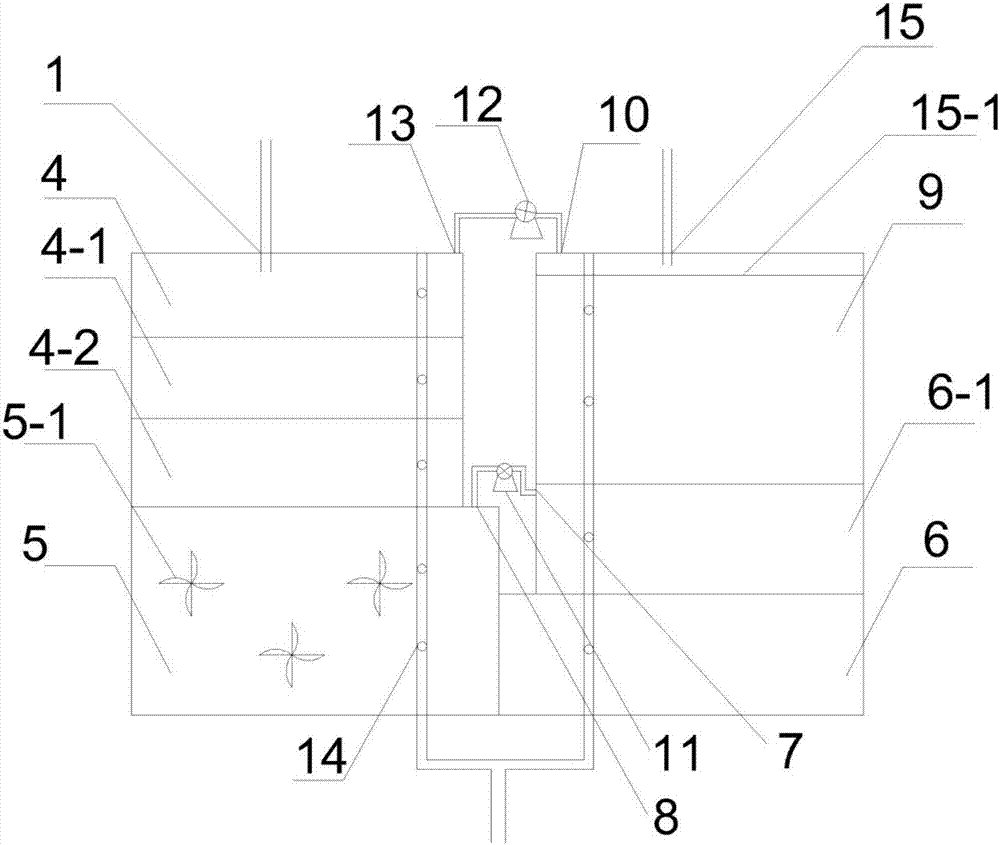

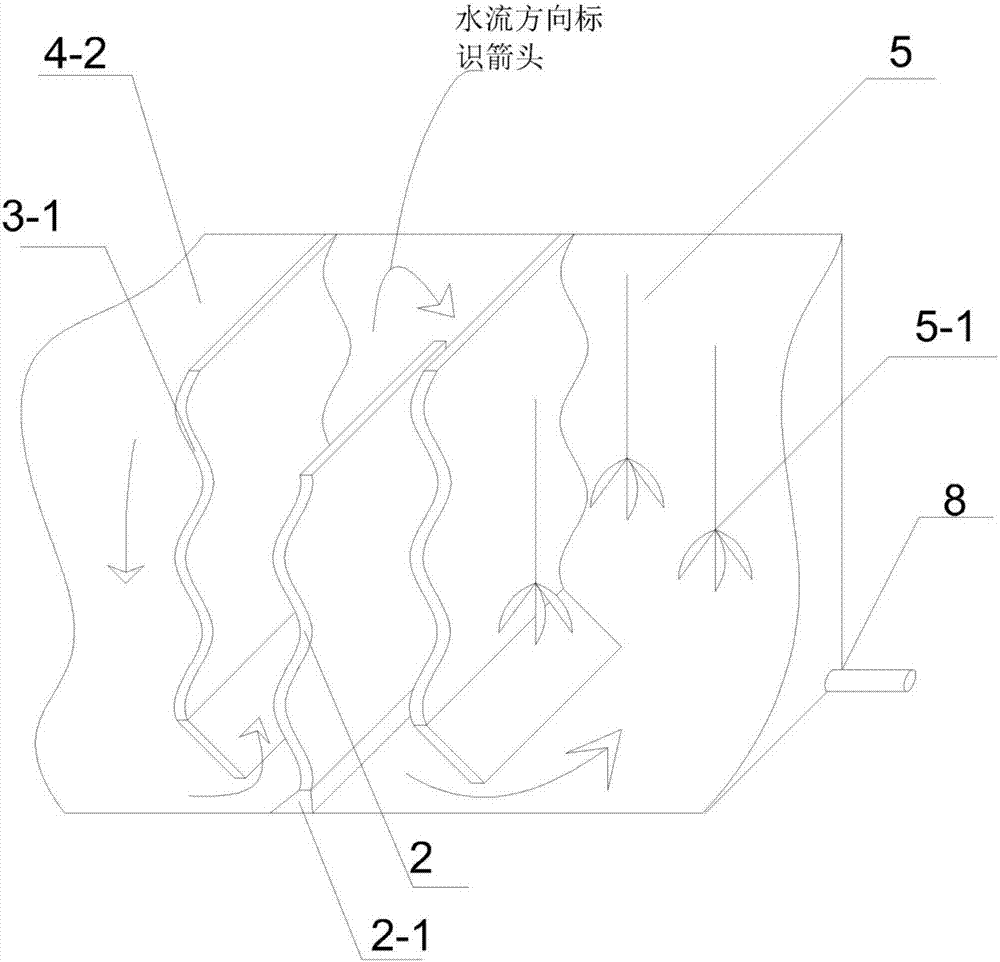

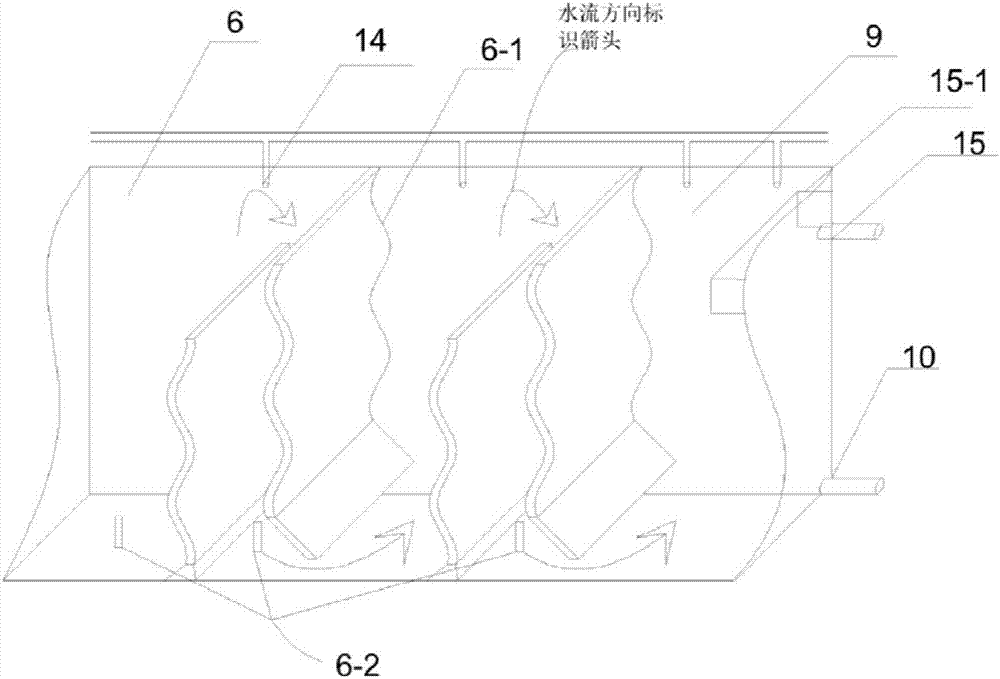

[0033] like figure 1 As shown, the AAO process water treatment equipment provided by the present invention includes anaerobic compartment A4, anaerobic compartment B4-1, anaerobic compartment C4-2, anoxic compartment 5, aerobic compartment A, aerobic compartment Chamber B6-1 and precipitation chamber 9, the anaerobic compartment A4, anaerobic compartment B4-1, anaerobic compartment C4-2, anoxic compartment 5, aerobic compartment A, aerobic compartment B6 -1 and the settling chamber 9 are provided with a triangular connection base 2-1 connected to the bottom of the AAO process water treatment equipment fixed wave-shaped baffle 2, the upper end of the wave-shaped baffle 2 and the top of the AAO process water treatment equipment stay There are intervals; the anaerobic compartment A4, anaerobic compartment B4-1, anaerobic compartment C4-2, anoxic compartment 5, aerobic compartment A, aerobic compartment B6-1 and sedimentation compartment 9 Both are provided with wave-shaped baffl...

Embodiment 2

[0036] like figure 1 As shown, the AAO process water treatment equipment provided by the present invention includes anaerobic compartment A4, anaerobic compartment B4-1, anaerobic compartment C4-2, anoxic compartment 5, aerobic compartment A, aerobic compartment Chamber B6-1 and precipitation chamber 9, the anaerobic compartment A4, anaerobic compartment B4-1, anaerobic compartment C4-2, anoxic compartment 5, aerobic compartment A, aerobic compartment B6 -1 and the sedimentation chamber 9 are provided with a triangular connection base 2-1 and the bottom of the AAO process water treatment equipment fixed wave-shaped baffle 2, the upper end of the wave-shaped baffle 2 and the top of the AAO process water treatment equipment stay There are intervals; the anaerobic compartment A4, anaerobic compartment B4-1, anaerobic compartment C4-2, anoxic compartment 5, aerobic compartment A, aerobic compartment B6-1 and sedimentation compartment 9 There are wave-shaped baffles 3-1 fixedly co...

Embodiment 3

[0041] like figure 1 and figure 2 As shown, on the basis of Example 1, the AAO process water treatment equipment 1 adopts a reinforced concrete structure, with proper anti-corrosion treatment on the inner wall, and adopts a semi-underground structure. Set up NaHCO in the anaerobic compartment A4 3 Alkalinity regulator inlet to prevent possible excessive acidification of anaerobic compartment A, anaerobic compartment B and anaerobic compartment C.

[0042] The branch-shaped porous aeration head 1-5 comprises a straight pipe 1-5-1 and three branch pipes 1-5-2, and one end of the straight pipe 1-5-1 connects with the movable joint 1-5-4. The aeration port is connected, and the three branch pipes 1-5-2 are connected to the other end of the straight pipe. The three branch pipes 1-5-2 are provided with a through hole 1-5-3 on the same side of the circumferential wall and the three branch pipes 1 -5-2 The other end away from the straight pipe is sealed, and when the aeration port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com