Non-dissolving antibacterial cellulose acetate and preparation method and application thereof

A cellulose acetate, non-dissolving technology, applied in the field of non-dissolving antibacterial cellulose acetate and its preparation, can solve the problems of particle agglomeration or uneven distribution, antibacterial particles falling off and free, reducing the antibacterial performance of the film, etc. Less, more effective antibacterial activity, high antibacterial efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

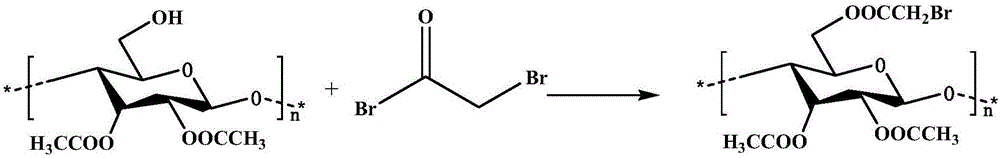

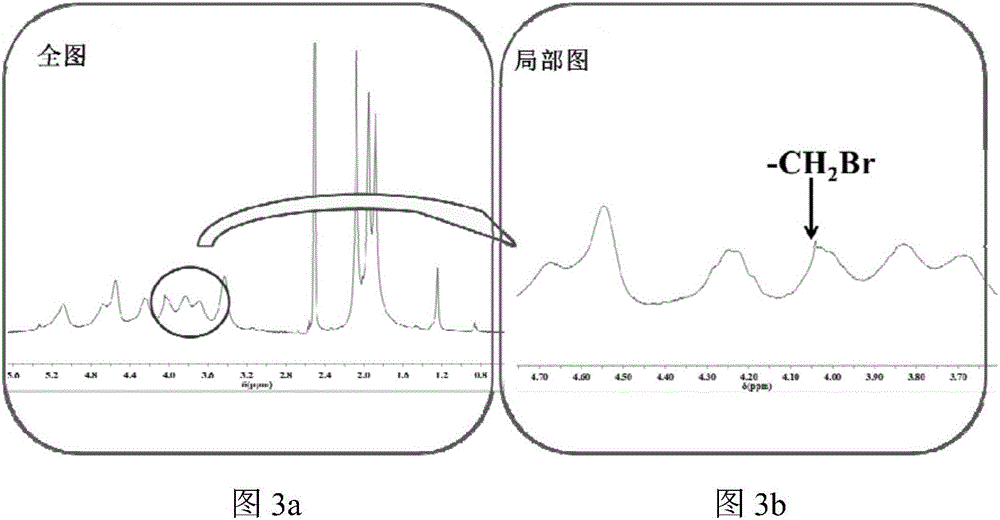

[0048] (1) In a reaction vessel, dissolve 20g of cellulose acetate in 250mL of N,N-dimethylformamide with a water content of <0.01wt.%, and prepare a colorless and transparent cellulose acetate with a mass concentration of 80g / L prime solution;

[0049] (2) Under the condition of 1000rpm in an ice-water bath and a stirring speed, 16.8g (the amount of the substance equivalent to the hydroxyl group in the cellulose acetate of 2.0eq) bromoacetyl bromide is added dropwise to the reaction vessel, and in the process of adding, ensure The temperature of the liquid phase in the reaction vessel is maintained at 0-5°C;

[0050] (3) After the dropwise addition, the reaction system of cellulose acetate and bromoacetyl bromide was raised to 25° C., and the reaction was continued for 18 hours at a stirring speed of 1000 rpm to obtain the initial product solution;

[0051] (4) Add 2.5L of deionized water to the reaction vessel, precipitate the cellulose acetate, and then wash it with deionize...

Embodiment 2

[0059] (1) In a reaction vessel, dissolve 20g of cellulose acetate in 250mL of N,N-dimethylformamide with a water content of <0.01wt.%, and prepare a colorless and transparent cellulose acetate with a mass concentration of 80g / L prime solution;

[0060] (2) Under the condition of 1100rpm in an ice-water bath and a stirring speed, 21.0g (the amount of the substance equivalent to the hydroxyl group in the cellulose acetate of 2.5eq) bromoacetyl bromide is added dropwise to the reaction vessel, and in the process of adding, ensure The temperature of the liquid phase in the reaction vessel is maintained at 0-5°C;

[0061] (3) After the dropwise addition, the reaction system of cellulose acetate and bromoacetyl bromide was raised to 25° C., and the reaction was continued for 18 hours at a stirring speed of 1100 rpm to obtain the initial product solution;

[0062] (4) Add 2.5 L of deionized water to the reaction vessel, precipitate the cellulose acetate, and then wash it with deion...

Embodiment 3

[0079] (1) In a reaction vessel, dissolve 20g of cellulose acetate in 250mL of N,N-dimethylformamide with a water content of <0.01wt.%, and prepare a colorless and transparent cellulose acetate with a mass concentration of 80g / L prime solution;

[0080] (2) Under the condition of 1200rpm in an ice-water bath and a stirring speed, 25.1g (the amount of the substance equivalent to the hydroxyl group in the cellulose acetate of 3.0eq) bromoacetyl bromide is added dropwise to the reaction vessel, and in the process of adding, ensure The temperature of the liquid phase in the reaction vessel is maintained at 0-5°C;

[0081] (3) After the dropwise addition, the reaction system of cellulose acetate and bromoacetyl bromide was raised to 25° C., and the reaction was continued for 18 hours at a stirring speed of 1200 rpm to obtain the initial product solution;

[0082] (4) Add 2.5L of deionized water to the reaction vessel, precipitate the cellulose acetate, and then wash it with deioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com