Demethylated lignin-based resorcinol-phenol-formaldehyde resin adhesive and preparation method thereof

A technology based on resorcinol and demethylation, applied in adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problem of high curing temperature of phenolic resin and high cost of resorcinol , low lignin activity and other problems, to achieve the effect of increasing phenolic hydroxyl content, good economic value, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

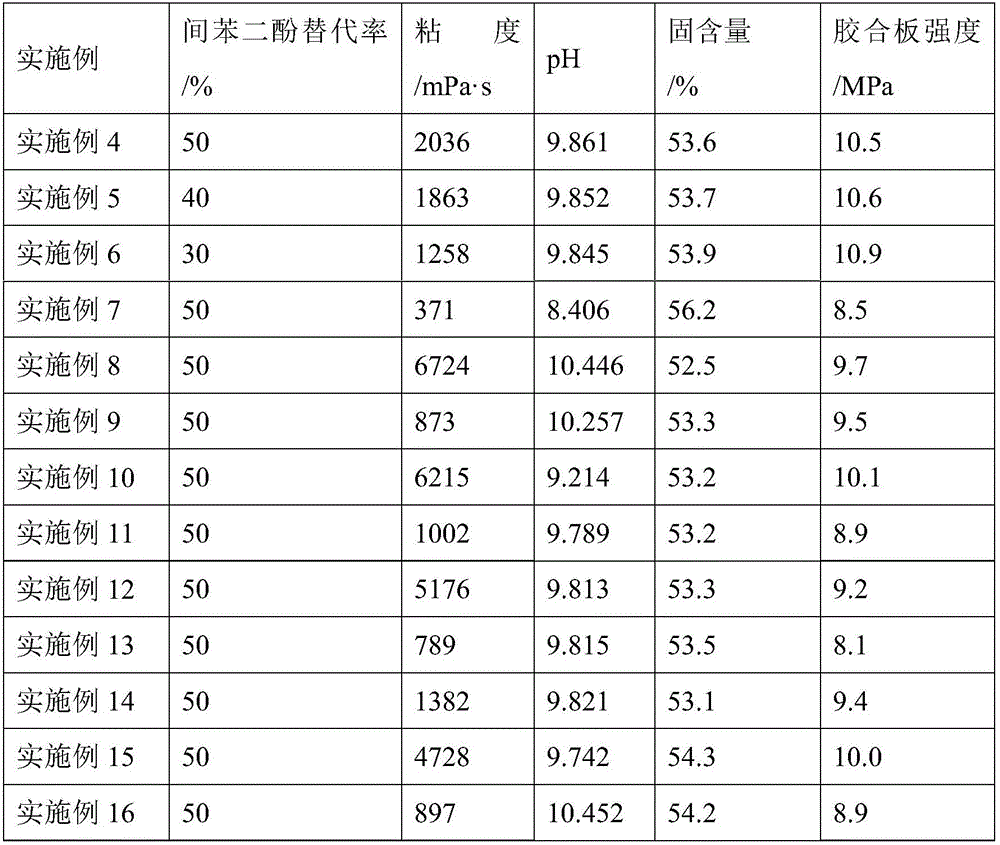

Examples

Embodiment 1

[0027] Enzymatic lignin demethylation pretreatment: add 50g of enzymatic lignin to sodium sulfide aqueous solution (dissolve 9g sodium sulfide in 100g water), turn on the stirring paddle to fully dissolve lignin, then heat up to 100°C, add 5g Sulfur, 40g of n-dodecylmercaptan and 2g of sodium borohydride, reacted for 180min, diluted with water after the reaction and adjusted the pH value to 2, centrifuged to obtain demethylated lignin, washed with water until neutral, and dried in a lyophilizer to obtain Pure demethylated lignin with a yield of 90%.

Embodiment 2

[0029] Alkali lignin demethylation pretreatment: Add 50g of alkali lignin into sodium sulfide aqueous solution (5g of sodium sulfide dissolved in 100g of water), turn on the stirring paddle to fully dissolve lignin, then raise the temperature to 90°C, add 3.5g of sulfur , 30g of n-dodecylmercaptan and 3g of sodium borohydride, reacted for 60min, diluted with water after the reaction and adjusted the pH value to 2, centrifuged to obtain demethylated lignin, washed to neutrality and put into a freeze dryer to dry to obtain pure The yield of demethylated lignin was 87%.

Embodiment 3

[0031] Enzymatic lignin demethylation pretreatment: add 50g of enzymatic lignin to sodium sulfide aqueous solution (12.5g of sodium sulfide dissolved in 100g of water), turn on the stirring paddle to fully dissolve lignin, then raise the temperature to 110°C, add 2.5g of sulfur, 50g of n-dodecanethiol and 0.5g of sodium borohydride, react for 120min, add water to dilute and adjust the pH value to 2 after the reaction, centrifuge to obtain demethylated lignin, wash with water until neutral and put it into a freeze dryer Dry in medium to obtain pure demethylated lignin with a yield of 88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com