Sealing material with high temperature resistance and high rebound resilience and preparation method of sealing material

A sealing material and high-temperature-resistant technology, applied in the field of materials, can solve the problems of rubber sealing materials that cannot be used for a long time, compression rebound and sealing performance loss, component decomposition, etc., and achieve fast strain rebound response time, excellent heat insulation performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Second, the present invention also provides a preparation method of the sealing material, comprising the steps of:

[0048] (1) Mix A component and B component and stir evenly to prepare an impregnation solution.

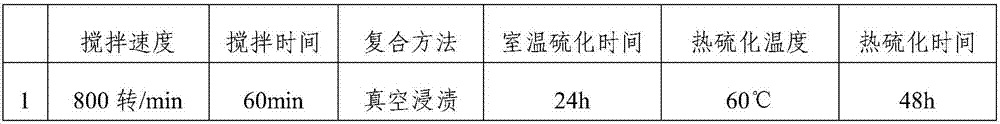

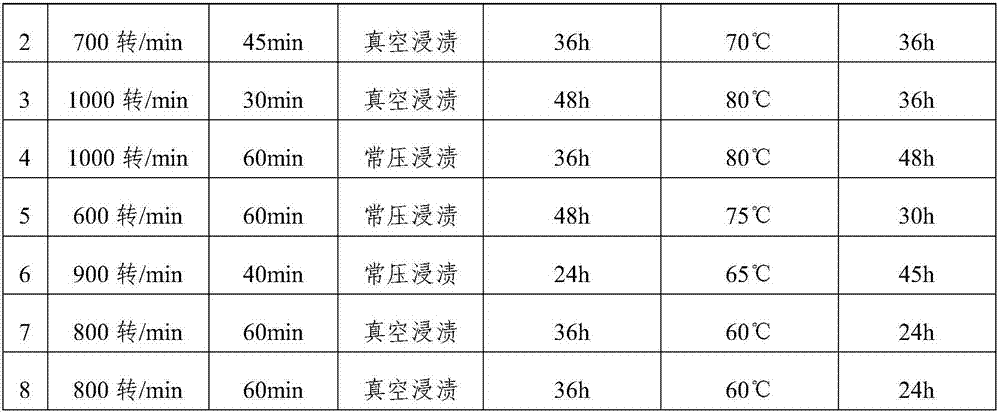

[0049] In some embodiments, in step (1), the stirring speed is controlled at 600-1000 rpm, and the stirring time is controlled at 30-60 minutes.

[0050] (2) The fiber is made into a fiber matrix.

[0051] In the present invention, the fiber matrix can be in various forms, such as fiber cotton, fiber felt, fiber blanket, fiber cloth, etc., and the preparation method can adopt existing processing methods, such as needle punching molding process.

[0052] The shape and size (eg thickness) of the fiber matrix can be determined as required.

[0053] (3) Composite the fiber matrix and the impregnating liquid to obtain a composite preform.

[0054] The composite method can choose normal pressure impregnation or vacuum impregnation.

[0055] (4) The composite pref...

Embodiment 1

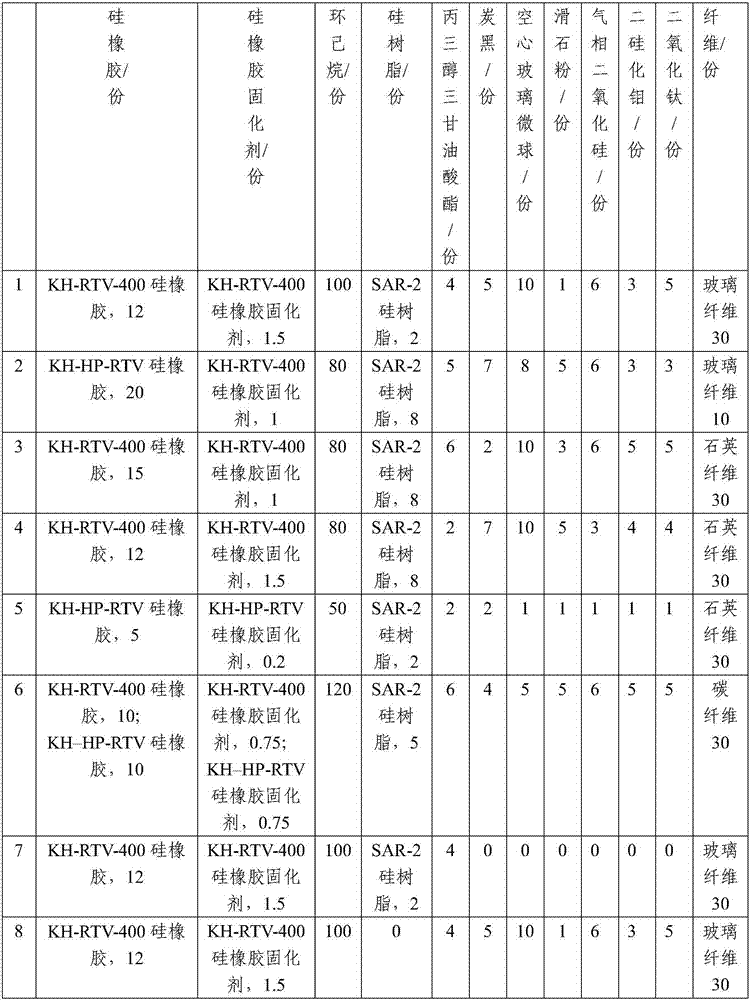

[0059] Weigh each preparation component according to Table 1.

[0060] (1) Mix and stir components A and B evenly, the stirring speed is controlled at 800 rpm, and after stirring for 60 minutes, an impregnation solution is obtained.

[0061] (2) The fiber is made into a fiber mat.

[0062] (3) The fiber mat is placed in a mold, and vacuum impregnated with the impregnating solution (vacuum degree is -0.06MPa) to be composited to obtain a composite preform.

[0063] (4) The obtained composite preform was vulcanized at room temperature for 24 hours, and then thermally vulcanized at 60° C. for 48 hours to obtain a rubber sealing material.

[0064] The preparation steps of Example 2 to Example 6 are basically the same as Example 1, and the differences are shown in Table 1 and Table 2 (1 to 6 in Table 1 and Table 2 correspond to Example 1 to Example 6, respectively).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com