Method for preparing micro-radio-frequency T-shaped power divider on metal base

A metal substrate and power divider technology, applied in metal material coating process, superimposed layer plating, coating, etc., can solve the problems that affect the performance of the structure, the process is complicated, and the strength is limited, so as to reduce the failure of production Chance, reduce process steps, avoid fragile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be described in detail below in combination with the above technical solutions and accompanying drawings.

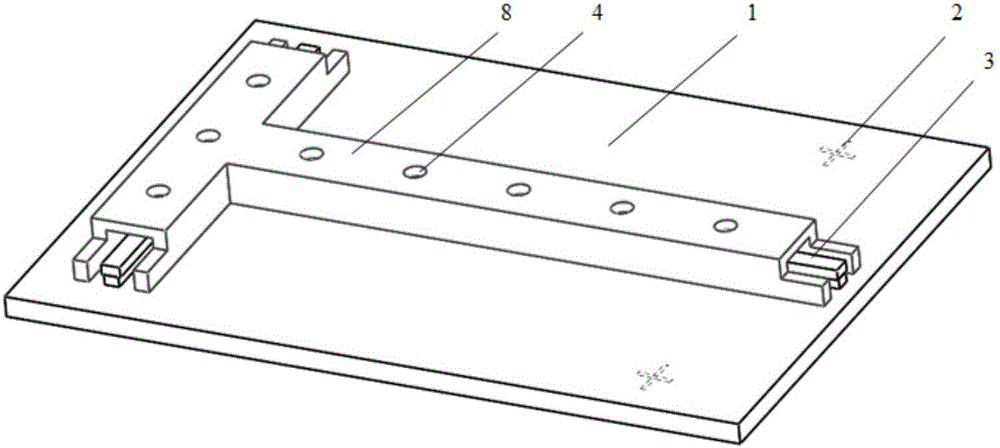

[0035] A micro-frequency T-shaped power splitter is prepared on the substrate, with figure 1 shown. The size of the base is 64×64×2mm. The specific steps to make the structure are as follows:

[0036] Step 1, pretreatment of the back of the substrate: Grinding and polishing the back of the substrate to make the surface roughness Ra less than 0.06 μm; wipe the substrate with acetone cotton balls, place them in acetone and ethanol for 15 minutes of ultrasonic cleaning respectively, and then use Rinse with deionized water and blow dry with nitrogen; put the cleaned substrate into a vacuum oven at 120°C for two hours and then cool to room temperature.

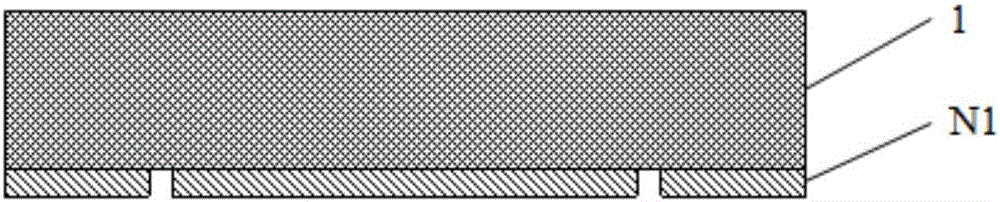

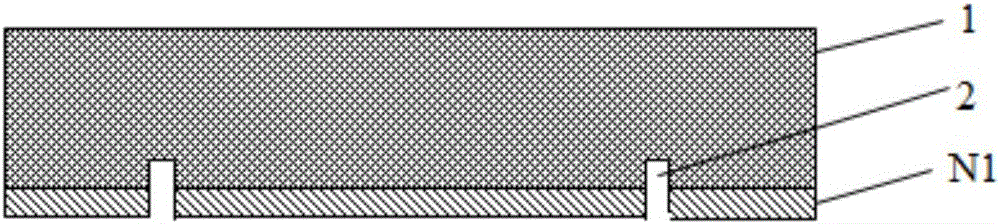

[0037] Step 2, making the back alignment mark: Spin-coat BN303 photoresist on the back of the substrate 1 with a thickness of 2-3 μm; through the phot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com