A vacuum electron beam welding method for solid rocket motor combustion chamber shell

A vacuum electron beam and solid rocket technology, which is applied in electron beam welding equipment, rocket engine devices, machines/engines, etc., can solve the problems of low production efficiency, high processing cost, and long production cycle, and achieve low processing cost and low labor cost. The effect of reducing strength and reducing labor intensity

Active Publication Date: 2014-06-04

SHANGHAI XINLI POWER EQUIP RES INST

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing electron beam welding mode has the obvious disadvantages of low production efficiency, high processing cost and long production cycle

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0043]

[0044] Post-welding non-destructive testing methods: appearance testing (VT) and radiographic testing (RT).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a vacuum electron beam welding method for a combustion chamber shell of a solid rocket motor, which comprises the following steps: determining a component assembly scheme and designing technical equipment; formulating a welding process scheme and technical regulations. Compared with the prior art, the method adopted by the present invention has the advantages and beneficial effects as follows: the quality of the weld seam is good, and the X-ray inspection confirms that there are no defects such as excessive air holes, unfused, cracks, etc.; the welding processing efficiency is high, the processing cost is low, and the single The production cycle is shortened and the labor intensity is reduced.

Description

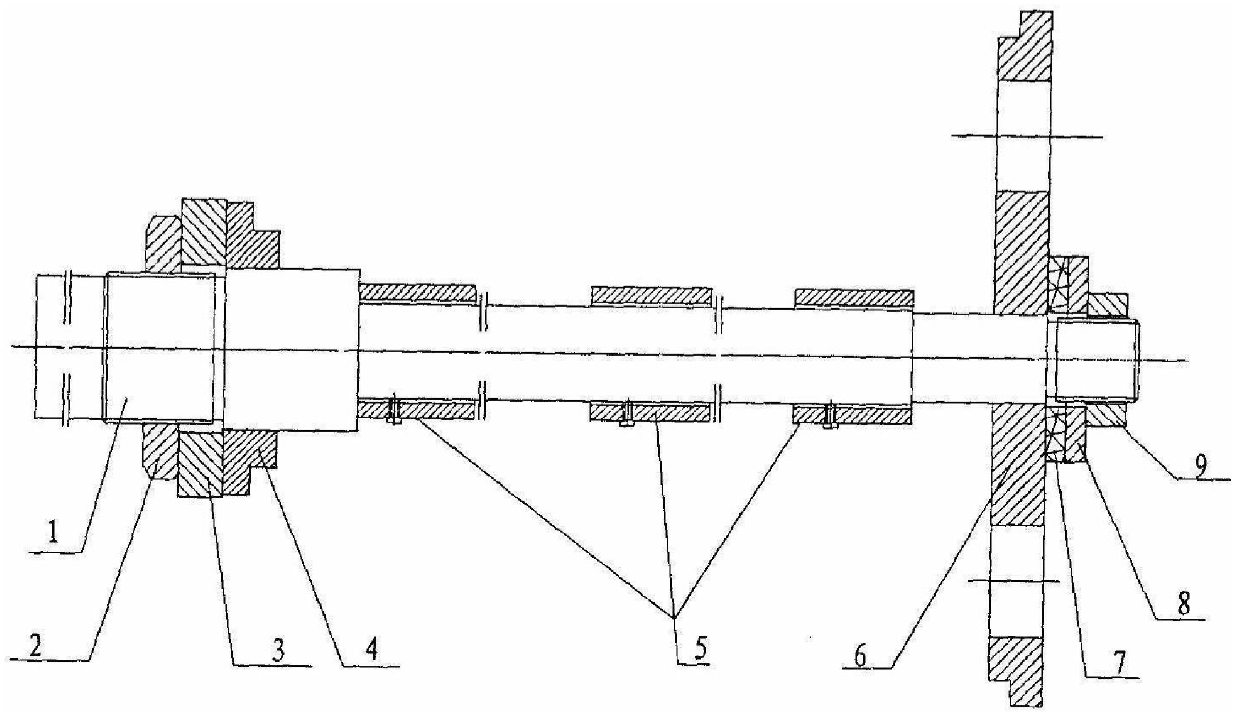

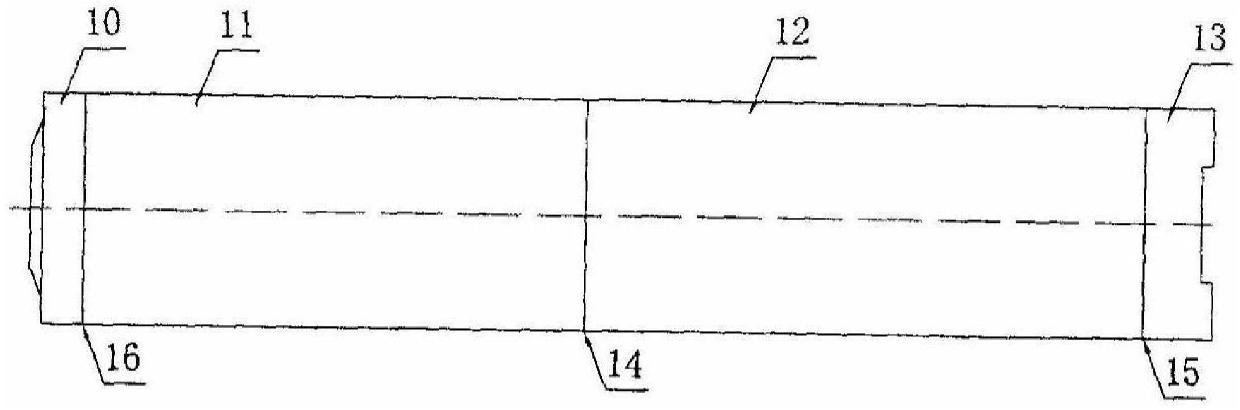

A vacuum electron beam welding method for a solid rocket motor combustion chamber shell Technical field The present invention relates to welding technique, specifically belong to the vacuum electron of solid rocket motor combustor thin-walled casing beam welding method. It is about the medium and low-alloy ultra-high-strength steel 30Cr3SiNiMoVA (hereinafter referred to as 30Cr3 steel) Small solid rocket motor combustor case. Background technique Combustion chamber casing is the important part of solid rocket motor, and its main body structure is long cylinder form, comprises front The head, the front spinning cylinder, the back spinning cylinder, and the rear head are made of low-alloy ultra-high-strength steel (30Cr3 steel), and the welding is realized The key process of connecting and forming the above four components is crucial to ensure the bearing capacity of the joint and the pressure bearing performance of the shell influences. The electron beam welding pro...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23K15/04B23K15/06F02K9/34

Inventor 王勇潘丽华王学峰

Owner SHANGHAI XINLI POWER EQUIP RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com