Feed additive for improving production performance of lactating sows, preparation method and application thereof

A feed additive and a technology for sucking sows are applied in the field of feed additives for improving the production performance of sucking sows and their preparation, and can solve the problems of overdosing, affecting the economic benefits of pig farmers, and difficult to treat diseases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

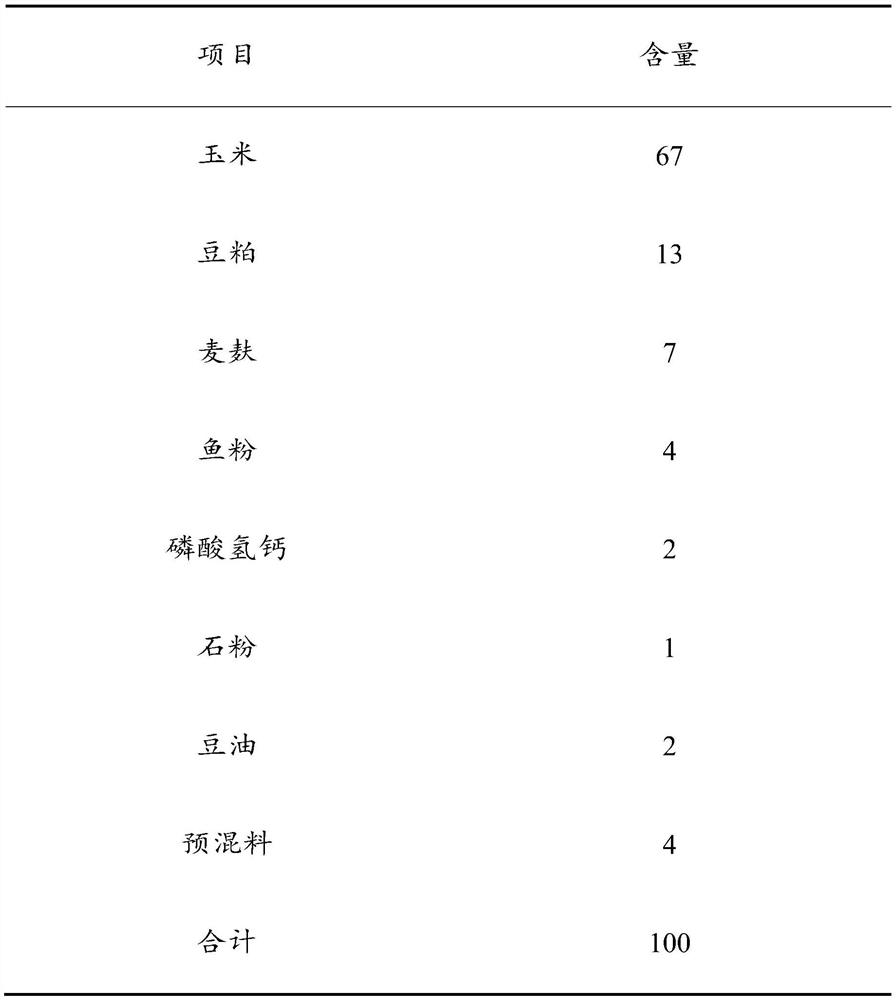

Method used

Image

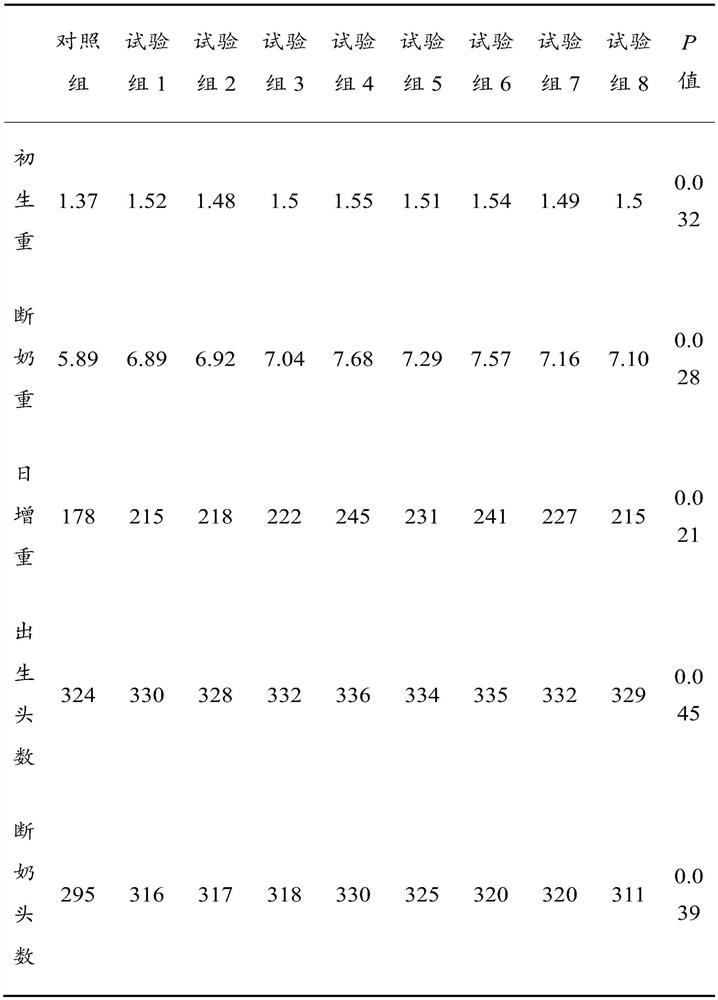

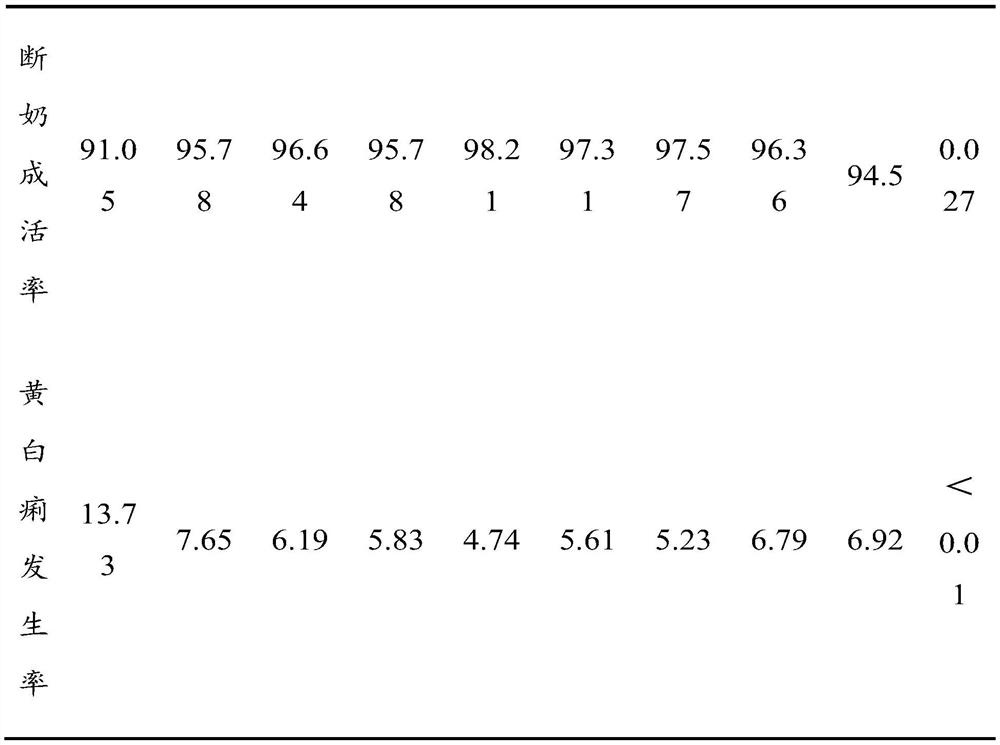

Examples

Embodiment 1

[0038] Mix 8 parts by weight of kelp, 10 parts by weight of motherwort, 15 parts by weight of blancia, 10 parts by weight of malt, 15 parts by weight of brown sugar, 20 parts by weight of licorice, 20 parts by weight of purslane and 10 parts by weight of portion of Bupleurum to obtain the first mixture.

[0039] The above-mentioned first mixture was pulverized into a 200-mesh powder, and decocted with water whose weight was 20 times the weight of the above-mentioned first mixture under the condition of 80° C. for 2 hours. Then it is evenly mixed with 10 parts by weight of Enteromorpha, 15 parts by weight of pyrroloquinoline quinone and 1.8 parts by weight of compound amino acid to obtain a feed additive. The compound amino acid contains arginine, valine, lysine and threonine in a weight ratio of 0.5:0.2:0.2:0.08.

[0040] The above-mentioned feed additive is added to the feed of lactating sows at 0.5% by weight.

Embodiment 2

[0042] Mix 10 parts by weight of kelp, 12 parts by weight of motherwort, 25 parts by weight of blancia, 12 parts by weight of malt, 12 parts by weight of brown sugar, 25 parts by weight of licorice, 10 parts by weight of purslane and 13 parts by weight of portion of Bupleurum to obtain the first mixture.

[0043] The above-mentioned first mixed material was pulverized into a 300-mesh powder, and decocted with water whose weight was 25 times the weight of the above-mentioned first mixed material under the condition of 100° C. for 5 hours. Concentrate the decoction after decoction, and dry at 100°C for 3 hours. Then it is evenly mixed with 20 parts by weight of Enteromorpha, 15 parts by weight of pyrroloquinoline quinone and 0.9 parts by weight of compound amino acid to obtain a feed additive. The compound amino acid contains arginine, valine, lysine and threonine in a weight ratio of 0.2:0.3:0.3:0.1.

[0044] The above-mentioned feed additive is added to the feed of lactating...

Embodiment 3

[0046] Mix 15 parts by weight of kelp, 15 parts by weight of motherwort, 25 parts by weight of blancia, 20 parts by weight of malt, 10 parts by weight of brown sugar, 15 parts by weight of licorice, 10 parts by weight of purslane and 8 parts by weight of portion of Bupleurum to obtain the first mixture.

[0047] The above-mentioned first mixture was pulverized into a 250-mesh powder, and decocted with water whose weight was 22.5 times the weight of the above-mentioned first mixture under the condition of 90° C. for 3.5 hours. Concentrate the decoction after decoction, and dry it at 105°C for 1.5h. Then it is evenly mixed with 25 parts by weight of Enteromorpha, 20 parts by weight of pyrroloquinoline quinone and 1.2 parts by weight of compound amino acids to obtain a feed additive. The compound amino acid contains arginine, valine, lysine and threonine in a weight ratio of 0.3:0.4:0.4:0.1.

[0048] The above-mentioned feed additive is added to the feed of lactating sows at 1%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com