Pickled mustard production method

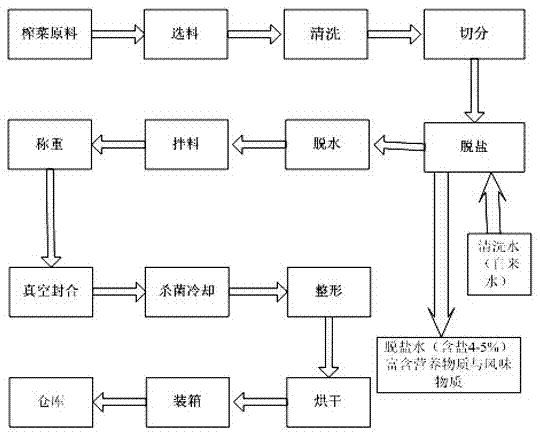

A production method and technology of pickled mustard, applied in the direction of climate change adaptation, food science, etc., can solve the problems of mustard mustard nutrition and flavor loss, environmental pollution, mineral loss, etc., to improve nutritional components and quality, simplify process procedures, The effect of reducing sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

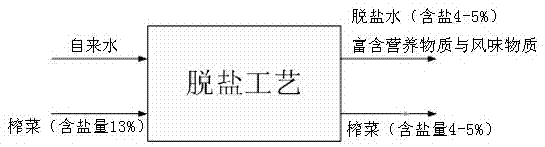

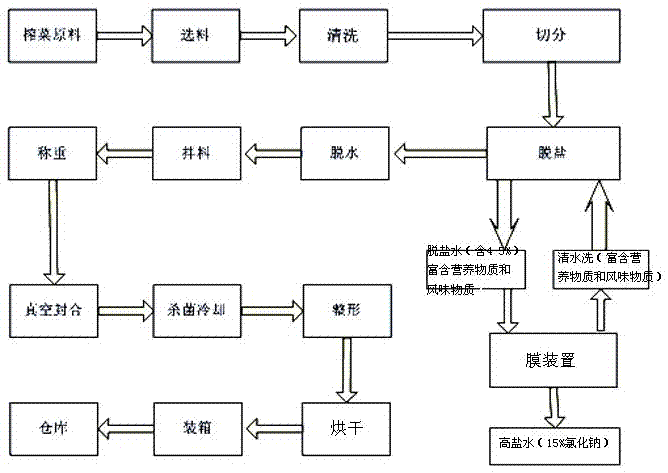

[0053] The original desalination process uses tap water as the cleaning water. Before cleaning, the salt content of mustard mustard is 13%. Reduce, when the salt content is reduced to 4-5%, the salt content of pickled mustard meets the requirements, such as figure 2 shown.

[0054] However, as the desalination process proceeds, nutrients and flavor substances are also washed out, resulting in desalinated water rich in nutrients and flavor substances.

[0055] The present invention adds a membrane device, which mainly separates the flavor substances and nutrients from the salt so that the cleaning water can be recycled; the membrane device mainly adopts an electrodialysis device.

[0056] Figure 5 As shown, the principle of the electrodialysis device is: electrodialysis is a phenomenon in which ions permeate through a selective ion exchange membrane under the action of a direct current electric field. Research on electrodialysis technology began in Germany in 1903, and ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com