Dual grinding head servo numerical control camshaft grinding machine

A camshaft, double grinding head technology, applied in the direction of grinding machine, belt grinding machine, grinding machine bed, etc., can solve the problems of loose layout, excessive size, complex structure, etc., and achieve stable installation, good thermal balance performance, and extended processing. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

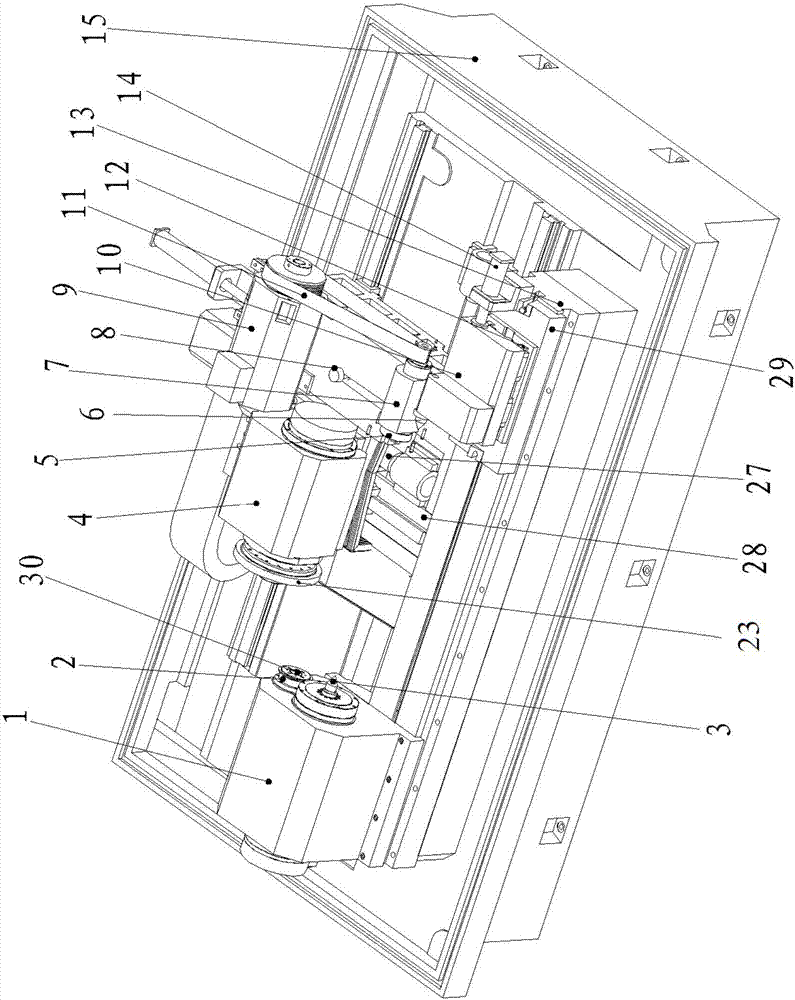

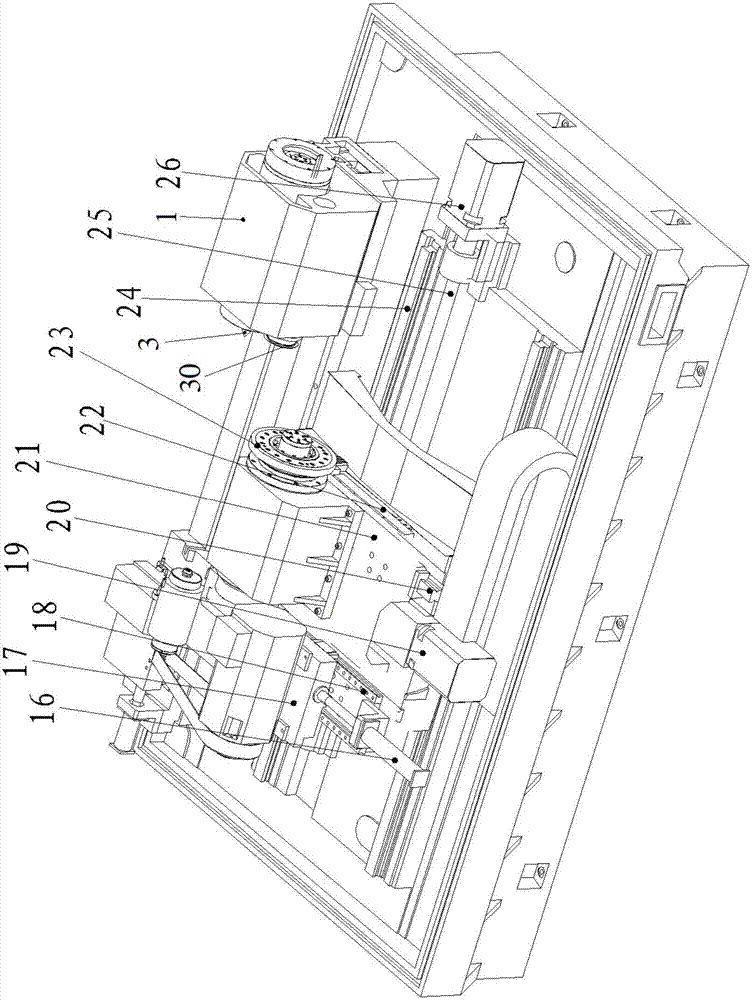

[0030] see figure 1 , figure 2 , a double grinding head follow-up CNC camshaft grinder, comprising a belt reduction device 11, a small grinding wheel spindle box 7, a small grinding wheel box spindle motor 9, a small grinding wheel frame body 17, a small grinding wheel frame guide rail 18, a large grinding wheel 23, and a large grinding wheel Box electric spindle 4, X-axis motor 19, X-axis feed backing plate 21, X-axis screw rod 27, X-axis guide rail 20, Z-axis motor 26, Z-axis feed backing plate 28, Z-axis screw rod 25, Z-axis Guide rail 24, tailstock top 6, tailstock slide table 10, tailstock guide rail 12, tailstock moving pad 29, headstock top 3, headstock 1, workbench 13 and bed 15.

[0031] The bed 15 is rectangular, the front side of the bed 15 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com