Preparation method of g-C3N4 with enhanced surface photovoltaic signal

A surface photovoltage and signal enhancement technology, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as poor controllability and cumbersome operation, and achieve short time, low price, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

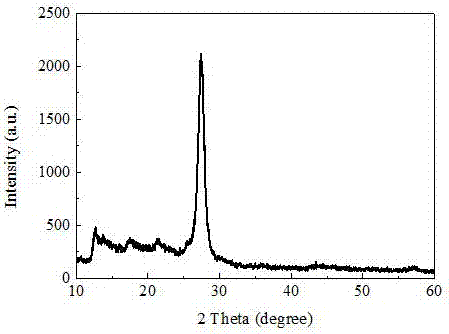

[0036] In the first step, urea is used as raw material, and the g-C 3 N 4 .

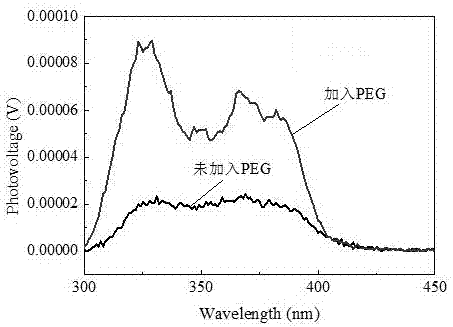

[0037] In the second step, the prepared g-C 3 N 4 g-C with the aid of surfactant 3 N 4 Perform hydrothermal treatment. Specifically, take 2.5 g g-C 3 N 4 Disperse in 60 mL deionized water, then add 0.05 g PEG6000, hydrothermally treat at 180 °C for 2 hours, and cool naturally to room temperature.

[0038] In the third step, the substance obtained in the second step is washed with deionized water and then washed with alcohol for 1-2 times, the powder is taken out and dispersed in alcohol, dried at 80°C to obtain a sample, and the surface photovoltage is tested.

[0039] Compared with Comparative Example 1, Example 1 added surfactant PEG6000.

[0040] figure 2 It is a comparison chart of surface photovoltage signals of products obtained in Comparative Example 1 and Example 1. It can be seen that after the second step of surfactant PEG6000 assisted hydrothermal treatment, g-C 3 N 4 The sur...

Embodiment 2

[0042] In the first step, urea is used as raw material, and the g-C 3 N 4 .

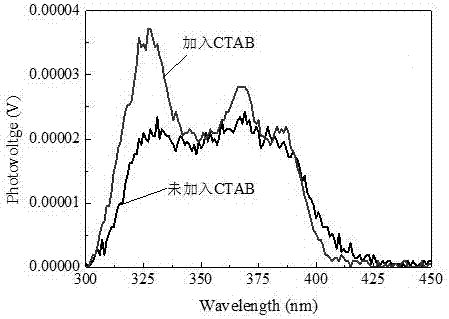

[0043] In the second step, the prepared g-C 3 N 4 g-C with the aid of surfactant 3 N 4 Perform hydrothermal treatment. Specifically, take 2.5 g g-C 3 N 4 Disperse in 40 mL deionized water, add 0.05 g CTAB, hydrothermally treat at 160 °C for 2 hours, and cool naturally to room temperature.

[0044] In the third step, wash with deionized water and then wash with alcohol for 1-2 times, take out the powder and disperse it in alcohol, dry at 80°C to obtain a sample, and test the surface photovoltage.

[0045] Compared with Comparative Example 1, the surfactant CTAB was added in Example 2, the hydrothermal temperature was 160°C, and the water dispersion volume was 40 mL.

[0046] image 3 It is a comparison chart of surface photovoltage signals of products obtained in Comparative Example 1 and Example 2. It can be seen that after the second step of surfactant CTAB assisted hydrothermal treatment...

Embodiment 3

[0048] In the first step, urea is used as raw material, and the g-C 3 N 4 .

[0049] In the second step, the prepared g-C 3 N 4 g-C with the aid of ionic liquids 3 N 4 Perform hydrothermal treatment. Specifically, take 2.0 g g-C 3 N 4 Disperse in 50 mL of deionized water, add 0.1 g of 1-ethyl-3-methylimidazolium nitrate, hydrothermally treat at 170 ° C for 1 hour, and naturally cool to room temperature.

[0050] In the third step, wash with deionized water and then wash with alcohol for 1-2 times, take out the powder and disperse it in alcohol, dry at 80°C to obtain a sample, and test the surface photovoltage.

[0051] Compared with Comparative Example 1, in Example 3, the ionic liquid 1-ethyl-3 methylimidazolium nitrate was added, the hydrothermal temperature was 170°C, the water dispersion volume was 50 mL, and the hydrothermal treatment was performed for 1 hour.

[0052] Figure 4 It is the surface photovoltage signal diagram of the product obtained in Comparative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com