Nutritional soil for cultivating eggplant seedlings and preparation method of nutritional soil

A technology of nutrient soil and eggplant, which is applied in the field of cultivation, can solve the problems of large fluctuations in the pH value of the substrate, the impact of eggplant high yield, and unfavorable growth of eggplant seedlings in the early stage, so as to achieve a wide range of uses, enhance crop absorption capacity, and help save resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

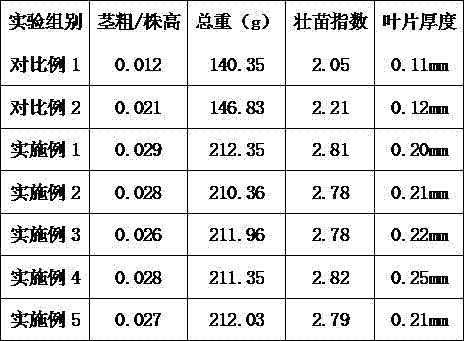

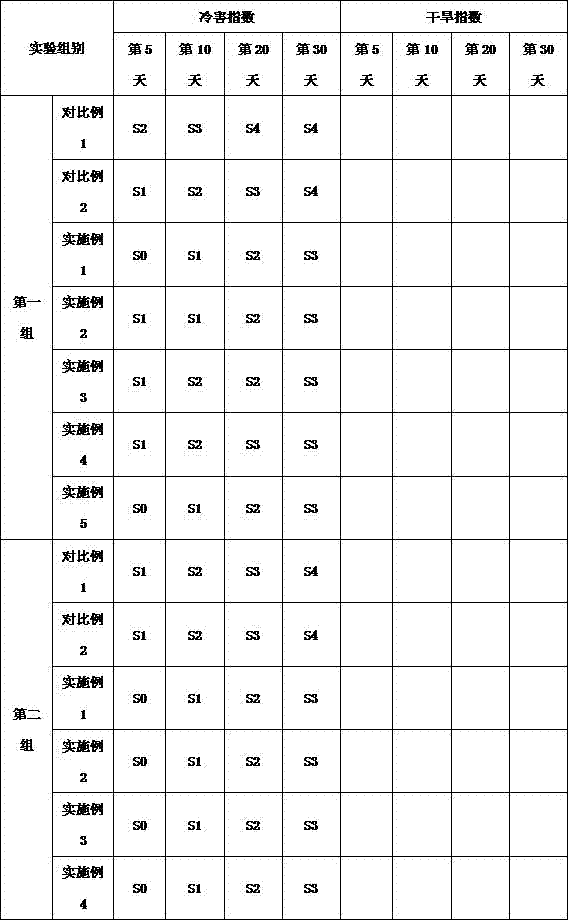

Examples

Embodiment 1

[0039] The present embodiment provides a kind of preparation method that is used for the nutrient soil of eggplant seedling raising, and described method is carried out according to the following steps:

[0040] a. Material preparation:

[0041] Mix the prepared fresh cow dung well, cover it with film and pile it up for fermentation. When the temperature reaches 60°C, turn it over and keep it within the temperature range for 5 days. During this period, turn it twice until the material turns dark brown and the temperature reaches 25°C When it is dried, crushed and set aside;

[0042] Add 0.1% of the commercially available bio-organic decomposing agent to the prepared paddy rice husk and chicken manure, mix well, and then pile up and ferment. When the temperature reaches 60°C, turn the pile and keep it in this temperature range for 14 days , turned over 7 times during the period, when the temperature of rice husk and chicken manure reached 25°C, and when the water content was red...

Embodiment 2

[0052] a. Material preparation:

[0053] Mix the prepared fresh cow dung well, cover it with film and pile it up for fermentation. When the temperature reaches 50°C, turn it over and keep it within the temperature range for 7 days. During this period, turn it twice until the material turns dark brown and the temperature reaches 30°C when, standby;

[0054] Add 0.5% of the commercially available bio-organic decomposing agent to the prepared paddy rice husk and chicken manure, mix well, and then pile up and ferment. When the temperature reaches 50°C, turn the pile and keep it in this temperature range for 21 days , turned over 12 times during the period, when the temperature of the rice husk and chicken manure reached 35°C and the moisture content was reduced to 30%, it was ready for use;

[0055] Mix the prepared soybean meal well, cover it with film and pile it up, then ferment it, and set it aside; the fermentation method is the common soybean meal fermentation method, the f...

Embodiment 3

[0064] a. Material preparation:

[0065] Mix the prepared fresh cow dung well, cover it with film and pile it up for fermentation. When the temperature reaches 55°C, turn it over and keep it within the temperature range for 6 days. During this period, turn it twice until the material turns dark brown and the temperature reaches 26°C when, standby;

[0066] Add 0.3% of the commercially available bio-organic decomposing agent to the prepared paddy rice husk and chicken manure, mix well, and then pile up and ferment. When the temperature reaches 55°C, turn the pile and keep it in this temperature range for 17 days , turned over 10 times during the period, when the temperature of the rice husk and chicken manure reached 30°C and the moisture content was reduced to 25%, it was ready for use;

[0067] Mix the prepared soybean meal well, cover it with film and pile it up, then ferment it and set it aside; the fermentation method is the common soybean meal fermentation method, the fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com