Ultraviolet light curing offset printing fluorescent anti-counterfeiting ink

A technology of anti-counterfeiting ink and ultraviolet light, which is applied in the field of ultraviolet curing offset printing fluorescent anti-counterfeiting ink and its preparation, which can solve the problems of insufficient adhesion, insufficient color effect, no anti-counterfeiting discoloration, etc., to improve adhesion and improve UV curing and drying Speed, good fluorescent color changing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

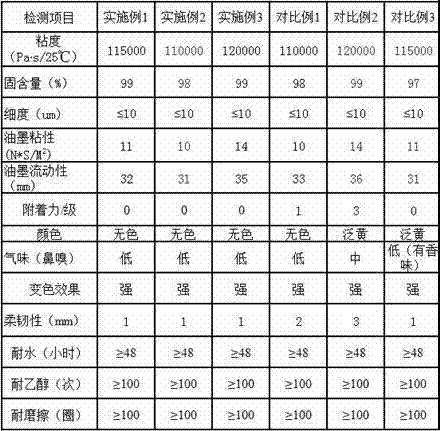

Examples

Embodiment 1

[0037] S1. Add 10.5 kg of propoxylated neopentyl glycol diacrylate, add 40 kg of EBECRYL811 polyester acrylate resin at a stirring speed of 800 rpm, then increase the rotating speed to 1600 rpm, and stir for 40 minutes to After dissolving completely, the semi-finished product is obtained after cooling down to normal temperature for subsequent use;

[0038] S2. Add 25 kg of colorless and reddish 365nm near-ultraviolet anti-counterfeiting fluorescent pigments, 15 kg of 8000 mesh talcum powder, 0.5 kg of silicone defoamer and 1 kg of silicone leveling agent to the semi-finished product and mix evenly at a stirring speed of 800 rpm / minute, stirring for 15 minutes; then increase the speed to 1600 rpm, stir for 40 minutes until the dispersion is uniform, the fineness is ≤ 10 μm, and the next step is performed after cooling to 2 room temperature;

[0039] S3. Reduce the rotating speed to 600 rpm, add 1 kg of TPO initiator and 7 kg of macromolecular photoinitiator 2-hydroxy-2methyl-...

Embodiment 2

[0041] S1. Add 15 kg of propoxylated neopentyl glycol diacrylate, add 50 kg of EBECRYL811 polyester acrylate resin at a stirring speed of 900 rpm, then increase the rotating speed to 1700 rpm, and stir for 30 minutes to After dissolving completely, the semi-finished product is obtained after cooling down to normal temperature for subsequent use;

[0042] S2. Add 19 kg of colorless and blue 254nm far ultraviolet anti-counterfeiting fluorescent pigment, 5 kg of 8000 mesh talcum powder, 0.5 kg of silicone defoamer and 0.5 kg of silicone leveling agent to the semi-finished product and mix evenly at a stirring speed of 900 RPM, stir for 10 minutes; then increase the speed to 1700 RPM, stir for 30 minutes until the dispersion is uniform, the fineness is ≤10μm, and then proceed to the next step after cooling down to room temperature;

[0043] S3. Reduce the rotating speed to 700 rpm, add 2 kg of TPO initiator and 8 kg of macromolecular photoinitiator 2-hydroxyl-2 methyl-1-(4-methylvi...

Embodiment 3

[0045] S1. Add 5 kg of propoxylated neopentyl glycol diacrylate, add 60 kg of EBECRYL811 polyester acrylate resin at a stirring speed of 1000 rpm, then increase the rotating speed to 1800 rpm, and stir for 20 minutes to After dissolving completely, the semi-finished product is obtained after cooling down to normal temperature for subsequent use;

[0046] S2. Add 15 kg of colorless and green infrared anti-counterfeiting fluorescent pigment, 6 kg of 8000-mesh talcum powder, 1 kg of silicone defoamer and 1 kg of silicone leveling agent to the semi-finished product and mix evenly at a stirring speed of 1000 rpm Minutes, stir for 5 minutes; then increase the speed to 1800 rpm, stir for 20 minutes until the dispersion is uniform, the fineness is ≤10μm, and the next step is performed after cooling to room temperature;

[0047] S3. Reduce the rotating speed to 800 rpm again, add 3 kilograms of TPO initiator and 9 kilograms of macromolecular photoinitiator 2-hydroxyl-2 methyl-1-(4-meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com