Modified asphalt waterproof membrane

A waterproof membrane and modified asphalt technology, which is applied in the direction of asphalt material adhesives, other rubber adhesives, adhesive types, etc., can solve the problem of unfavorable dip-coated tire surface, below minus 30 ℃, coiled materials Brittleness and other problems, to reduce the penetration and temperature sensitivity, reduce surface wrinkles, improve low temperature flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

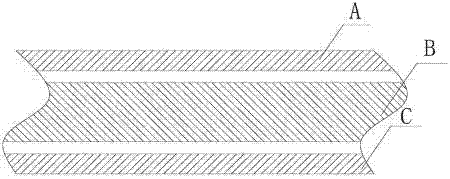

[0023] like figure 1 as shown, figure 1 It is a structural schematic diagram of a modified asphalt waterproof membrane proposed by the present invention.

[0024] refer to figure 1 , a kind of modified asphalt waterproof roll material proposed by the present invention, comprises base layer B, the upper surface layer A bonded on the base layer B and the lower surface layer C bonded under the base layer B, wherein the upper surface layer A and the base layer B is bonded with modified asphalt, base layer B and lower surface layer C are bonded with modified asphalt, base layer B is made of glass fiber film, and upper surface layer A is made of polyethylene film, high temperature resistant polyester film or fine sand The lower surface layer C is made of polyethylene film.

[0025] Wherein, modified asphalt is prepared according to the following steps:

[0026] a. Add 5 parts of carbon nanotubes to 6 parts of absolute ethanol in parts by weight and mix, then add 22 parts of sodi...

Embodiment 2

[0031]A modified asphalt waterproof roll material proposed by the present invention comprises a base layer B, an upper surface layer A bonded to the base layer B and a lower surface layer C bonded under the base layer B, wherein the upper surface layer A and the base layer B are Modified asphalt is used to bond each other, the base layer B and the lower surface layer C are bonded to each other by modified asphalt, the base layer B is made of glass fiber film, and the upper surface layer A is made of polyethylene film, high temperature resistant polyester film or fine sand Therefore, the lower surface layer C is made of polyethylene film.

[0032] Wherein, modified asphalt is prepared according to the following steps:

[0033] a. Add 8 parts of carbon nanotubes to 3 parts of absolute ethanol in parts by weight and mix, then add 26 parts of sodium hydroxide solution with a mass fraction of 5wt% to carry out ultrasonic dispersion once. The time for ultrasonic dispersion is 3 hour...

Embodiment 3

[0038] A modified asphalt waterproof roll material proposed by the present invention comprises a base layer B, an upper surface layer A bonded to the base layer B and a lower surface layer C bonded under the base layer B, wherein the upper surface layer A and the base layer B are Modified asphalt is used to bond each other, the base layer B and the lower surface layer C are bonded to each other by modified asphalt, the base layer B is made of glass fiber film, and the upper surface layer A is made of polyethylene film, high temperature resistant polyester film or fine sand Therefore, the lower surface layer C is made of polyethylene film.

[0039] Wherein, modified asphalt is prepared according to the following steps:

[0040] a. Add 7 parts of carbon nanotubes to 4 parts of absolute ethanol in parts by weight and mix, then add 25 parts of sodium hydroxide solution with a mass fraction of 6wt% to carry out ultrasonic dispersion once. The time of ultrasonic dispersion for one t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com