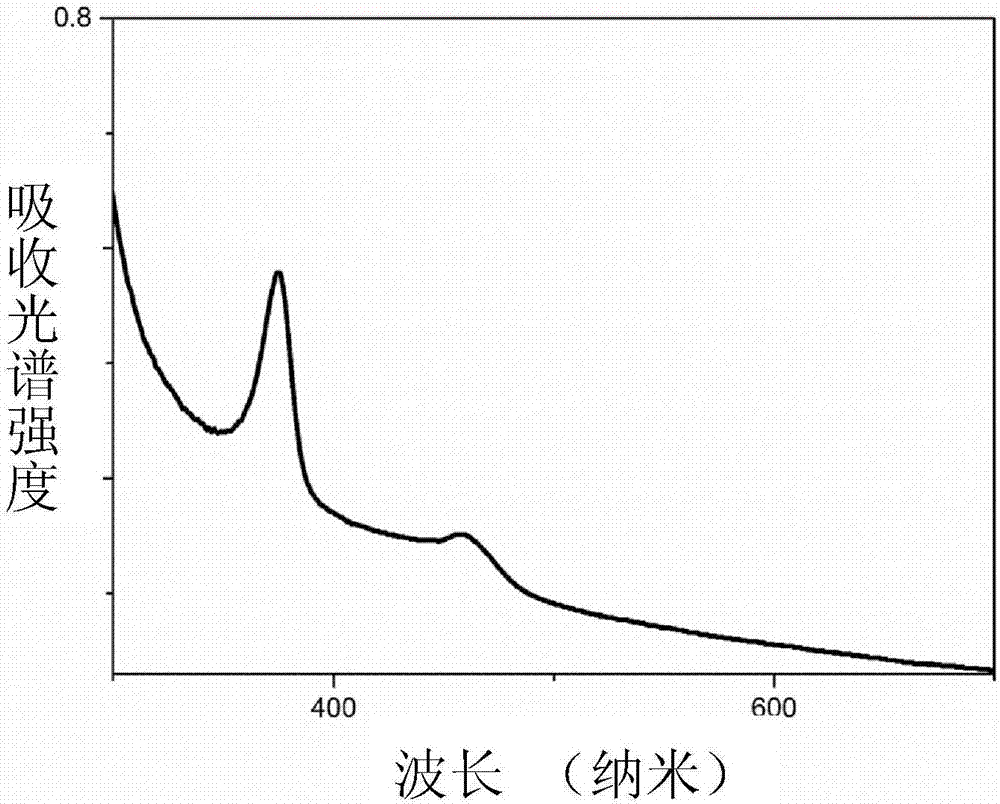

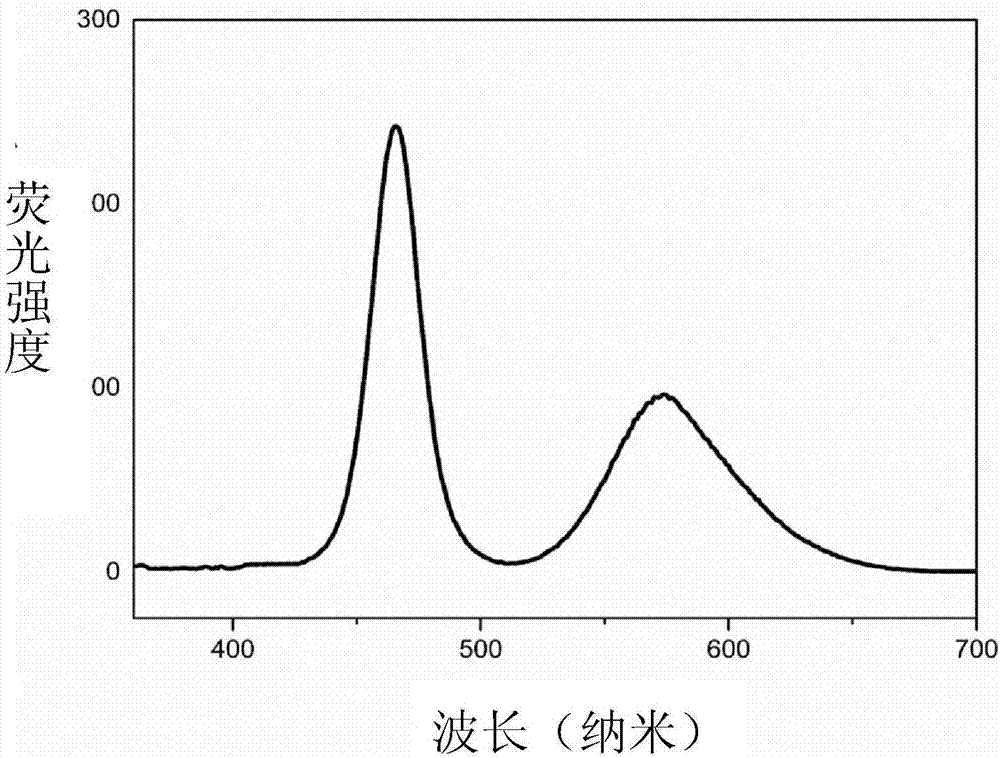

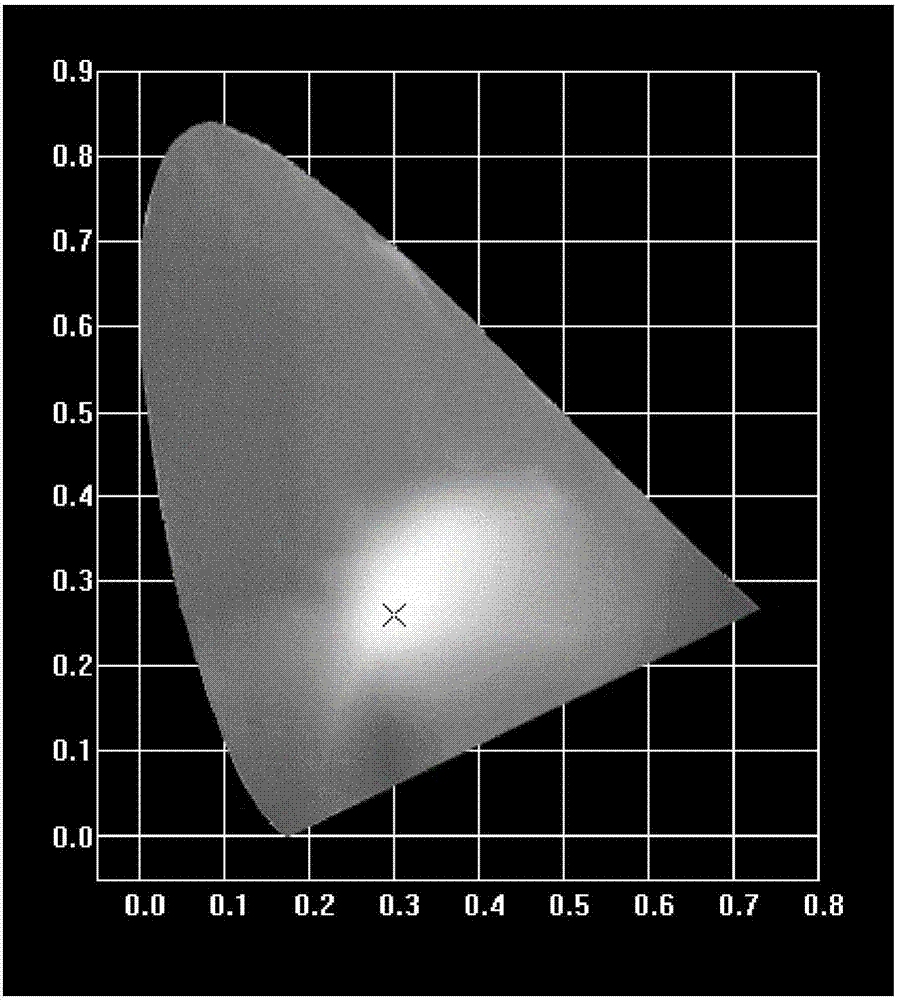

Method for preparing manganese-doped perovskite quantum dots capable of emitting high-brightness white light

A perovskite, high-brightness technology, applied in the field of manganese-doped perovskite quantum dot materials and their preparation, achieves the effects of simple equipment, narrow band-edge luminescence peaks, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: Preparation of white light Mn:CsPb 2 (Br / Cl) 5 Quantum dots, comprising the steps of:

[0024] 1) Mix and stir 25mL methanol and 10mL hexylamine in an ice-water bath (0°C); add 10mL HBr dropwise; remove the ice-water bath and stir at room temperature for 2 hours; remove the solvent (rotary evaporation 70°C.); Recrystallize in a mixture of ether and ethanol, filter; collect, dry (vacuum, 60°C, 24 hours) to produce CH 3 (CH 2 ) 5 NH 3 Br; stored in glove box (H 2 O2 <0.1ppm)

[0025] 2) Add 0.5mmol PbBr 2 , 0.33mmol CH obtained in step 1 3 (CH 2 ) 5 NH 3 Br was mixed and dissolved in 10ml DMF, 2.5mmol MnCl 2 4H 2 O and 0.165mmol CsBr were dissolved in 5ml DMF and ultrasonically dissolved completely to make the required precursor solution;

[0026] 3) Add the precursor solution obtained in step 2 dropwise to the stirred 100ml toluene solution in sequence, and react for 1.5-2.5 hours to obtain the quantum dot material.

Embodiment 2

[0027] Embodiment 2: Preparation of white light Mn:CsPb 2 (Br / Cl) 5 Quantum dots, comprising the steps of:

[0028] 1) Mix and stir 25mL methanol and 10mL hexylamine in an ice-water bath (0°C); add 10mL HBr dropwise; remove the ice-water bath and stir at room temperature for 2 hours; remove the solvent (rotary evaporation 70°C.); Recrystallize in a mixture of ether and ethanol, filter; collect, dry (vacuum, 60°C, 24 hours) to produce CH 3 (CH 2 ) 5 NH 3 Br; stored in glove box (H 2 O2 <0.1ppm)

[0029] 2) 0.53mmol PbBr 2 , 0.32mmol CH obtained in Step 1 3 (CH 2 ) 5 NH 3 Br was mixed and dissolved in 6ml DMF, 2.5mmol MnCl 2 4H 2 O and 0.1mmol CsBr were dissolved in 3ml DMF and ultrasonically dissolved completely to make the required precursor solution;

[0030] 3) Add the precursor solution obtained in step 2 dropwise to the stirred 100ml toluene solution in sequence, and react for 1.5-2.5 hours to obtain the quantum dot material.

Embodiment 3

[0031] Embodiment 3: Preparation of white light Mn:CsPb 2 (Br / Cl) 5 Quantum dots, comprising the steps of:

[0032] 1) Mix and stir 25mL methanol and 10mL hexylamine in an ice-water bath (0°C); add 10mL HBr dropwise; remove the ice-water bath and stir at room temperature for 2 hours; remove the solvent (rotary evaporation 70°C.); Recrystallize in a mixture of ether and ethanol, filter; collect, dry (vacuum, 60°C, 24 hours) to produce CH 3 (CH 2 ) 5 NH 3 Br; stored in glove box (H 2 O2 <0.1ppm)

[0033] 2) Add 0.32mmol PbBr 2 , 0.23mmol CH obtained in step 1 3 (CH 2 ) 5 NH 3 Br was mixed and dissolved in 8ml DMF, 2.5mmol MnCl 2 4H 2 O and 0.12mmol CsBr were dissolved in 4ml DMF and ultrasonically dissolved completely to make the required precursor solution;

[0034] 3) Add the precursor solution obtained in step 2 dropwise to the stirred 100ml toluene solution in sequence, and react for 1.5-2.5 hours to obtain the quantum dot material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com