A class of room temperature molten salt and its preparation method and application

A room temperature molten salt and molten salt technology, applied in the field of low-temperature electrolytic aluminum, can solve the problems of affecting metals, competing reactions, and reducing the green characteristics of ionic liquids, and achieve the effects of stability in the air, high conductivity, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

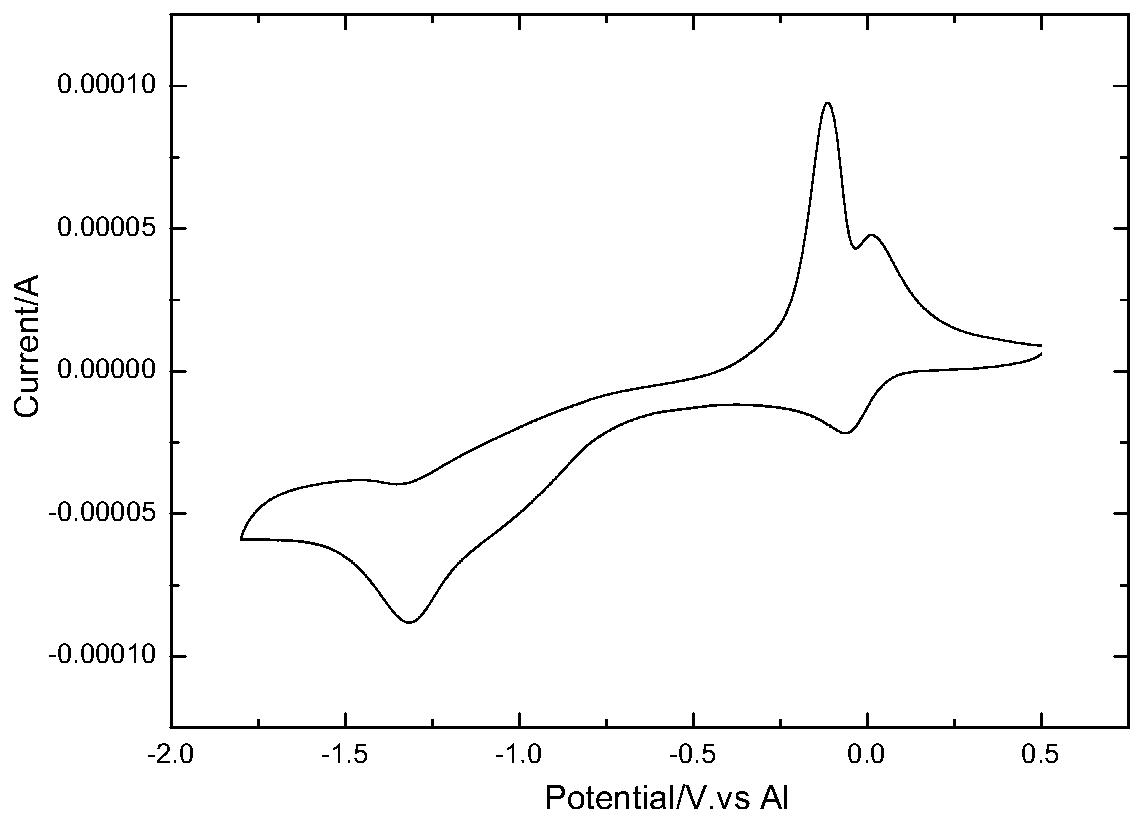

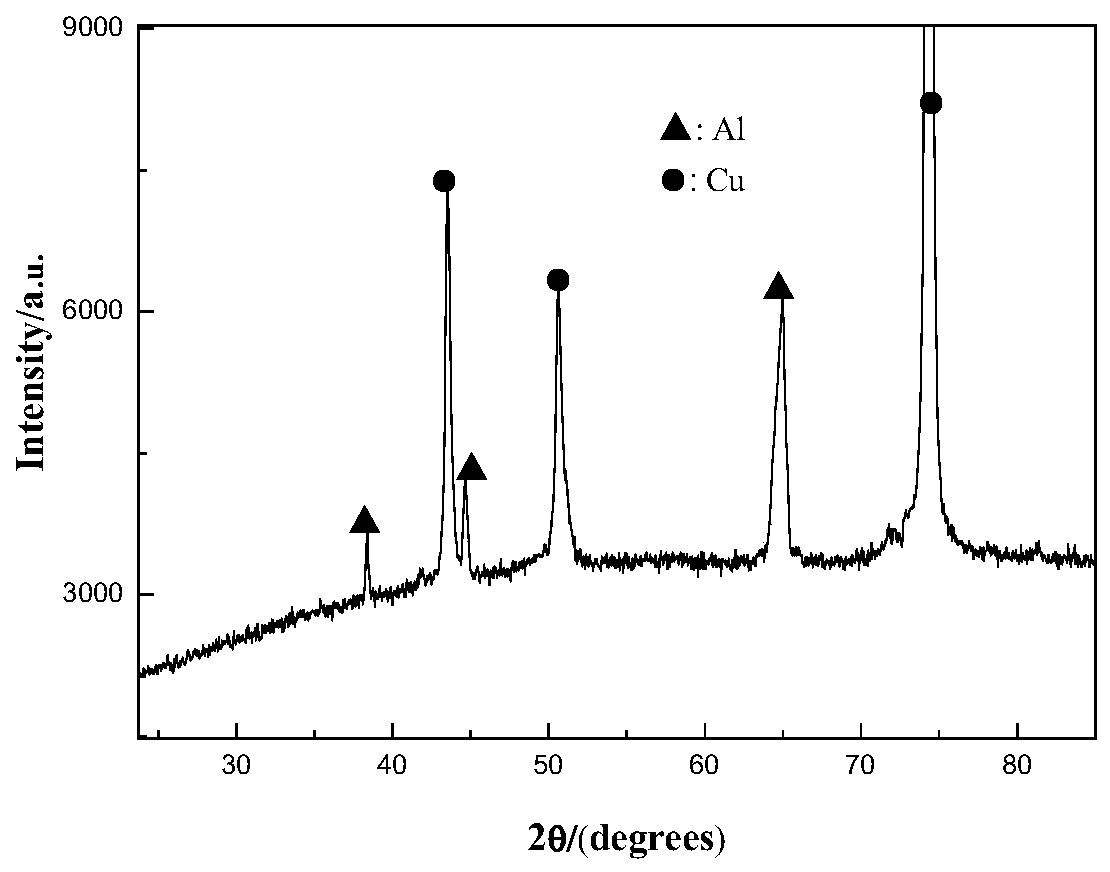

[0048] At room temperature 25°C, weigh AlCl at a molar ratio of 0.5:1 3 3.33g and 4.40g of ethylene carbonate were placed in a 10ml beaker and stirred at a stirring speed of 700r / min for 20min to obtain a uniform, stable and transparent molten salt at room temperature. The obtained system was electrolyzed with a copper substrate at the potential of -0.8V (vs Al) for 5 hours, the anode was a graphite rod, and the effective area immersed in the liquid surface was 1.5cm 2 . Do XRD detection and ICP detection on the electrodeposited product. XRD detection proves that the product is metallic aluminum. Through calculation, it can be seen that the yield reaches 95.50%, and the purity of aluminum detected by ICP is 98.00%.

Embodiment 2

[0050] At room temperature 25°C, weigh AlCl at a molar ratio of 0.1:1 3 and ethylene carbonate in a 10ml beaker, stirred at a stirring speed of 500r / min for 10min to obtain a uniform, stable and transparent molten salt at room temperature. The obtained system is electrolyzed at -0.6V (vs Al) potential for 8 hours with a copper substrate, the anode is a graphite rod, and the effective area of immersion in the liquid surface is 1.5cm 2 . Do XRD detection and ICP detection on the electrodeposited product. XRD detection proves that the product is metallic aluminum. Through calculation, it can be seen that the yield reaches 90.50%, and the purity of aluminum detected by ICP is 97.00%.

Embodiment 3

[0052] At room temperature 25°C, weigh AlCl at a molar ratio of 1:1 3 and ethylene carbonate were placed in a 10ml beaker, and stirred at a stirring speed of 800r / min for 30min to obtain a uniform, stable and transparent molten salt at room temperature. The obtained system was electrolyzed for 4 hours at the potential of -0.6V (vs Al) using a copper substrate, the anode was a graphite rod, and the effective area immersed in the liquid surface was 1.5cm 2 . Do XRD detection and ICP detection on the electrodeposited product. XRD detection proves that the product is metallic aluminum. Through calculation, it can be seen that the yield reaches 95.20%, and the purity of aluminum detected by ICP is 99.00%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com