A compact wide-chord high-head small-flow axial flow cooling fan for motors

A cooling fan, small flow technology, applied in the direction of engine cooling, cooling/ventilation, axial flow pump, etc., can solve the problems of reducing fan stability margin and pressure rise capacity, reducing fan efficiency, leakage loss, etc. Improve cooling effect, improve heat dissipation efficiency, improve the effect of working ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

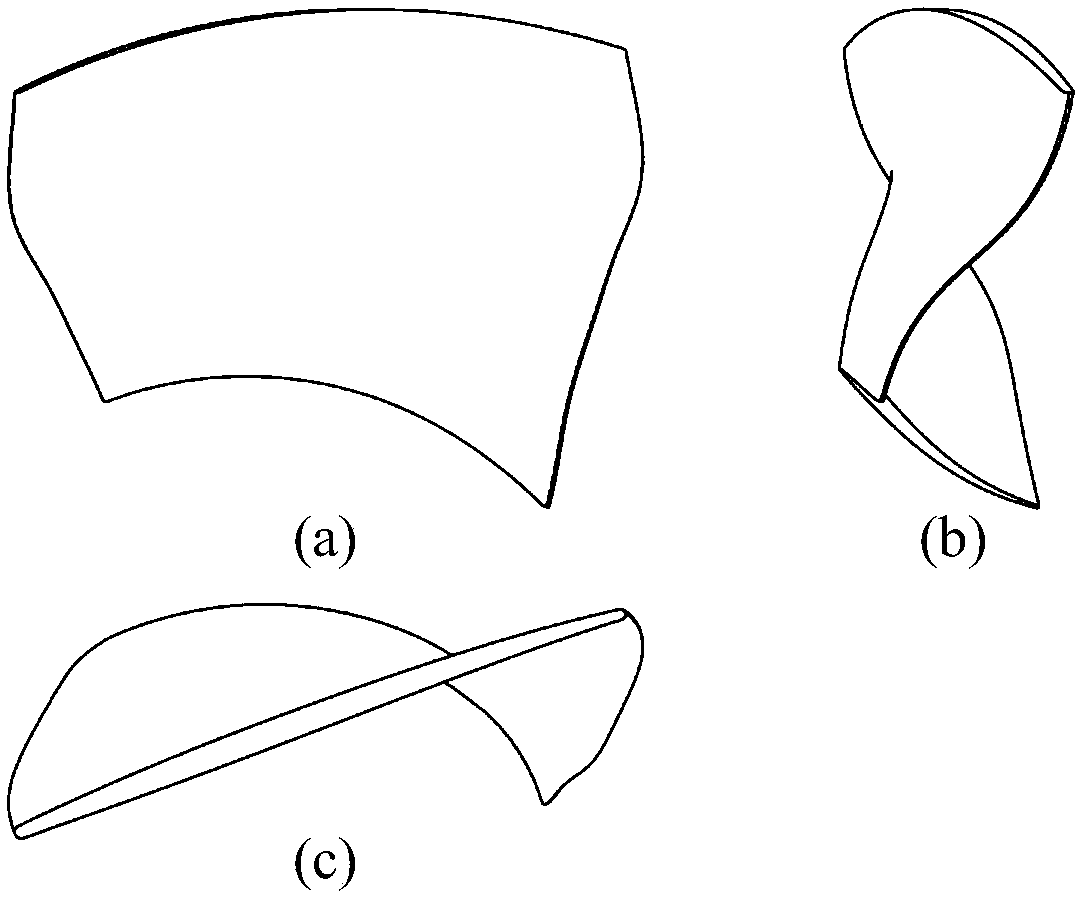

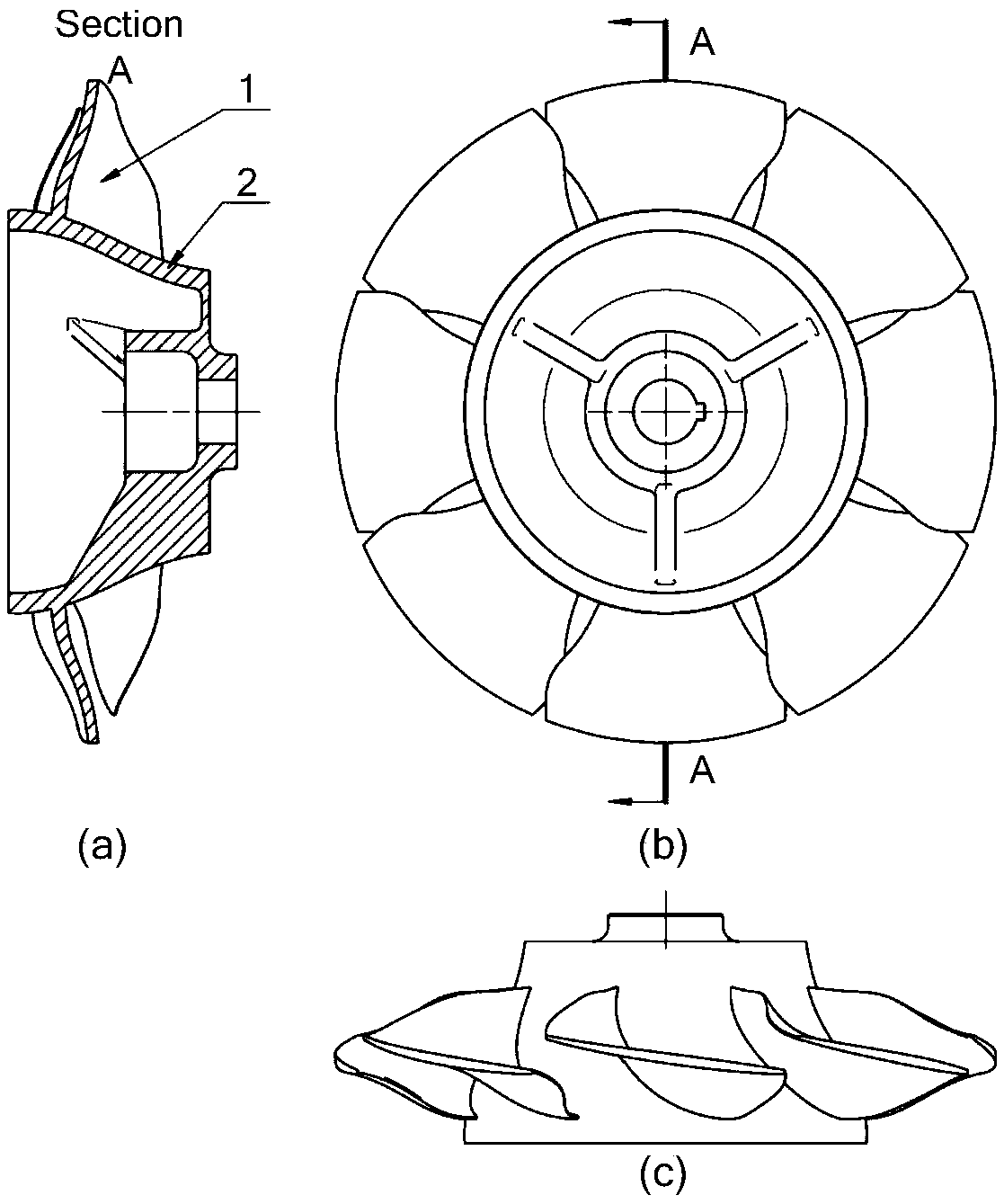

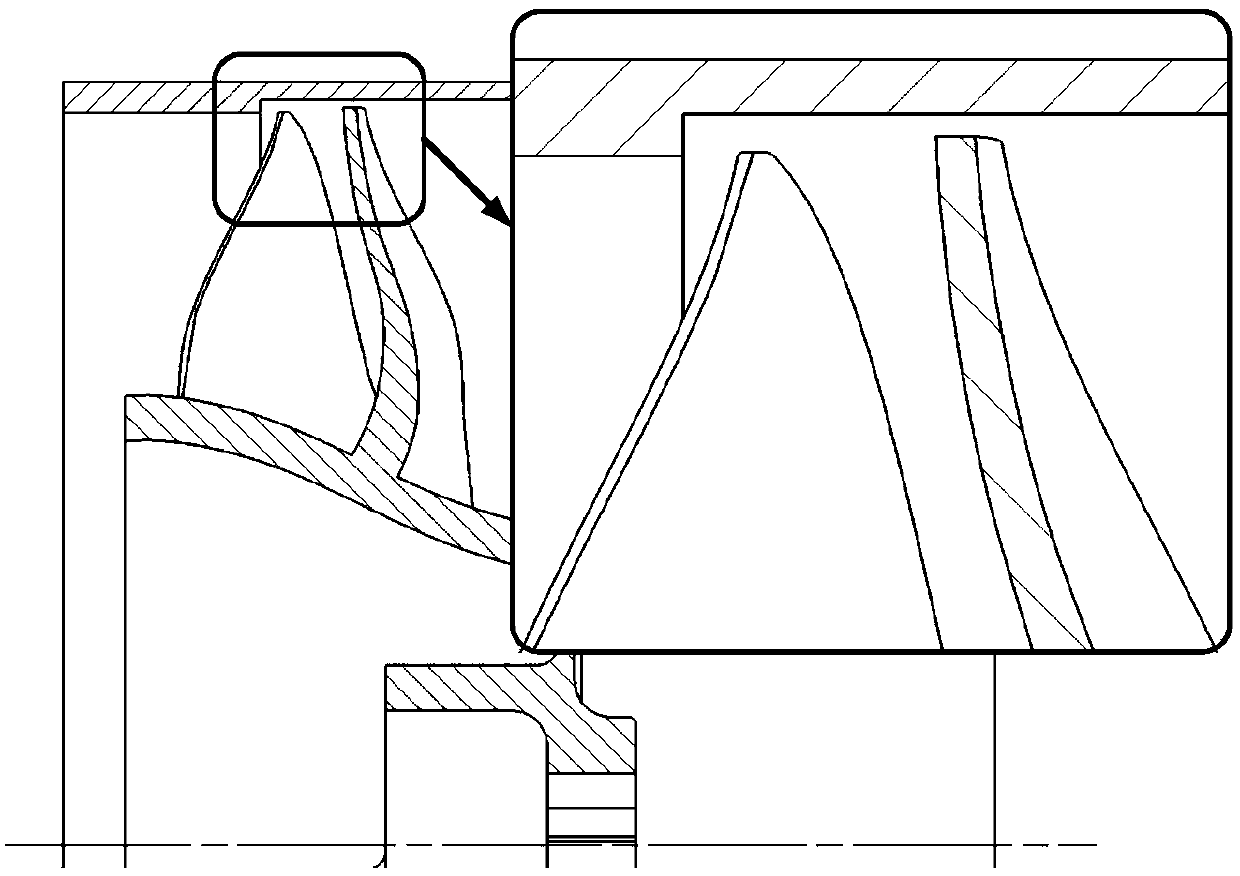

[0018] 1. See Figure 1-Figure 6 ,

[0019] 1. Inwardly shrinking tapered hub profile design. The disclosed cooling axial flow fans for generators all adopt the design of equal outer diameter and equal inner diameter. Aiming at the heat dissipation requirement of the rectifier diode at the small radius, the present invention adopts the design of the conical wheel hub with inner contraction, and by increasing the radius of the hub at the inlet, the axial speed is kept within a suitable range, so as to ensure the relative intake angle in the velocity triangle of the fan element level When it is lower than 75 degrees (the angle between the relative speed and the axis), it achieves the purpose of reducing the flow rate and improving the working capacity. At the same time, by reducing the radius of the hub at the outlet to make it consistent with the radius of the hub of the generator cooling zone, an expanding meridian flow is formed. Generally speaking, under normal circumstanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com