Oxygen-enriched combustion supercritical carbon dioxide cyclone furnace

A carbon dioxide and oxygen-enriched combustion technology, applied in the direction of indirect carbon dioxide emission reduction, combustion equipment, lighting and heating equipment, etc., to achieve the effects of increasing oxygen concentration, reducing operating costs, and simplifying the pulverization system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below in conjunction with accompanying drawing:

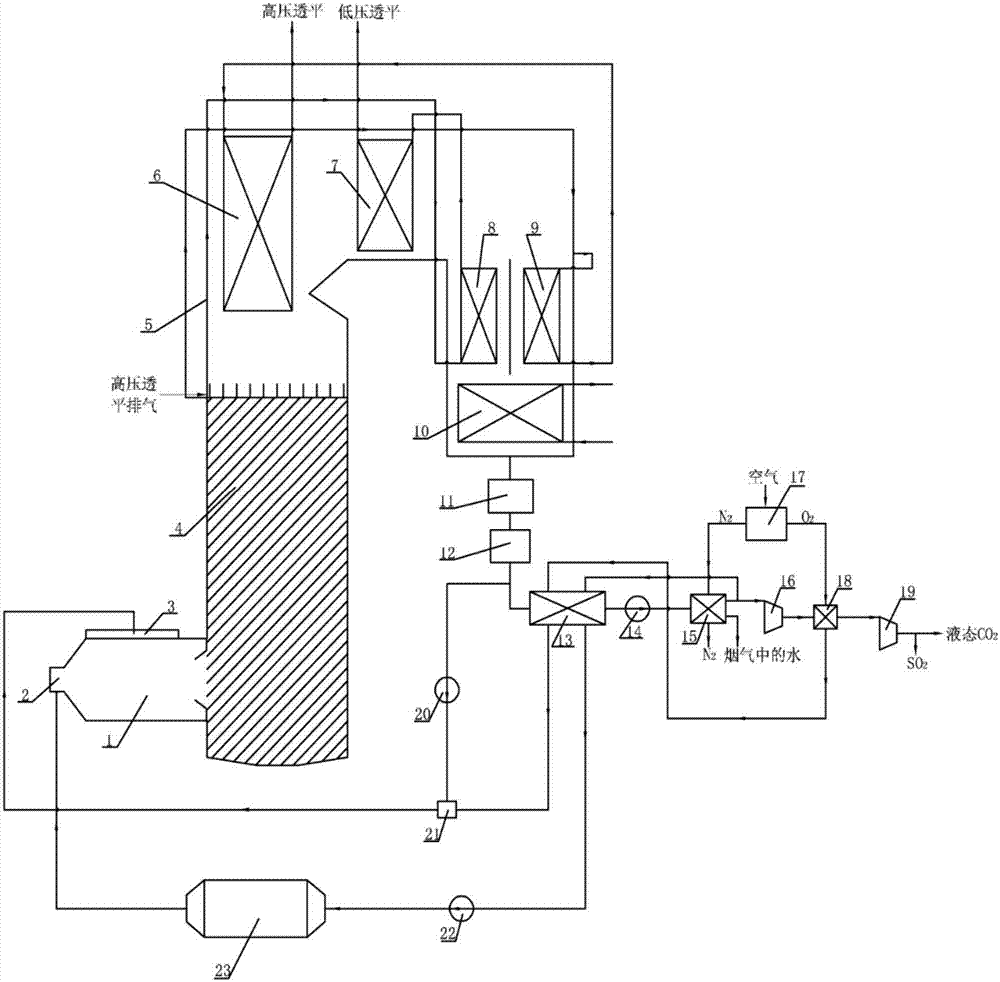

[0021] refer to figure 1 , the oxygen-enriched combustion supercritical carbon dioxide cyclone furnace of the present invention comprises a cyclone furnace and a tail flue gas comprehensive treatment system, the cyclone furnace comprises a cyclone tube 1 and a supercritical carbon dioxide boiler; the tail flue gas comprehensive treatment system comprises an SCR denitrification device 11, a dust removal Device 12, gas-gas heat exchanger 13, condenser 15, first-stage compressor 16, air separation device 17, cooler 18, second-stage compressor 19, flue gas mixing device 21 and pulverizing system 23; cyclone The cylinder 1 is provided with a primary tuyere 2 and a secondary tuyere 3, the outlet of the cyclone 1 is connected with the inlet of the supercritical carbon dioxide boiler, and the outlet of the supercritical carbon dioxide boiler is connected with the inlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com