Heat-resistant coating layer with uniform and ordered pore sizes for lithium ion battery separator and preparation method of heat-resistant coating layer

A lithium-ion battery, heat-resistant coating technology, applied in the direction of secondary batteries, battery pack components, secondary battery repair/maintenance, etc., can solve the problem of weakening the energy output, power output and cycle life of lithium-ion batteries, which is difficult To ensure the uniformity of the coating pore size, the high price of the diaphragm, etc., to achieve the effect of facilitating large-scale production, avoiding porosity and air permeability, and the preparation method is simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

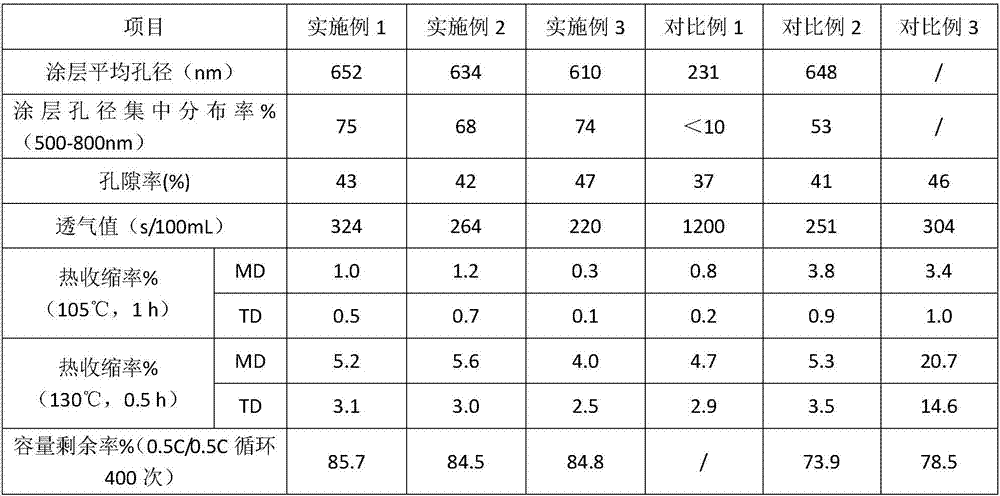

Examples

Embodiment 1

[0035] A heat-resistant coating with uniform and ordered pores is prepared by the following method:

[0036] (1) 10g weight average molecular weight Mw is 1.2×10 5 1. Add polyetherimide with a molecular weight distribution of Mw / Mn of 2 into 55g of N,N-dimethylacetamide solvent, stir and dissolve at 80°C. After the dissolution is complete, add 3g of alumina (average particle size 0.5μm), 1.3g of polyethylene glycol, and 0.6g of Tween 80, continue heating and stirring until completely dissolved, ultrasonically disperse for 45min, and cool and stand for 1h.

[0037] (2) Coat the prepared coating solution on both sides of the glass substrate and polyethylene microporous membrane respectively, place it in a constant temperature and humidity box with a temperature of 60°C and a humidity of 75% for 8 minutes, and wash with deionized water , and finally dried in hot air at 75°C to obtain a microporous coating film and a composite diaphragm respectively.

[0038] (3) The microporous...

Embodiment 2

[0044] A heat-resistant coating with uniform and ordered pores is prepared by the following method:

[0045] (1) The 10g weight average molecular weight Mw is 8×10 4 1. Add polyacrylonitrile with a molecular weight distribution Mw / Mn of 4 to 40 g of N,N-dimethylformamide, stir and dissolve at 70°C. After the dissolution is complete, add 1.5g polyvinylpyrrolidone and 0.4g Tween 60, continue heating and stirring until completely dissolved, then cool and stand for 1.5h.

[0046] (2) Coat the prepared coating solution on both sides of the glass substrate and the polyethylene microporous membrane respectively, place it in a constant temperature and humidity chamber with a temperature of 65°C and a humidity of 85% for 5 minutes, and wash with deionized water , and finally dried in hot air at 80°C to obtain a microporous coating film and a composite diaphragm respectively.

[0047] (3) The microporous coating film is separated from the glass substrate, and the pore size and its con...

Embodiment 3

[0053] A heat-resistant coating with uniform and ordered pores is prepared by the following method:

[0054] Different from Example 1, the 55g N,N-dimethylacetamide solvent in step (1) is replaced with 40g N,N-dimethylacetamide solvent, and the step (2) polyethylene microporous membrane is replaced with For the polypropylene non-woven membrane, the humidity is changed to 70%, and the storage time in the constant temperature and humidity box is changed to 10 minutes. All the other are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com