Shipborne continuous drying method of antarctic krill and shipborne continuous processing method of shelled shrimps of antarctic krill

A processing method and krill technology, applied in shrimp/lobster processing, crustacean processing, food drying, etc., can solve problems such as the problem of cooking soup discharge, the color of the shrimp body is not bright enough, and the fluorine in the shrimp shell penetrates into the muscle, etc. Reduce long-distance storage and transportation costs, obvious effects of inactivating enzymes and bacteria, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

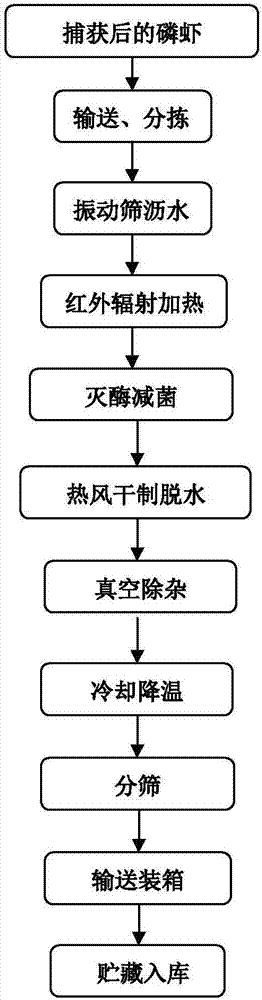

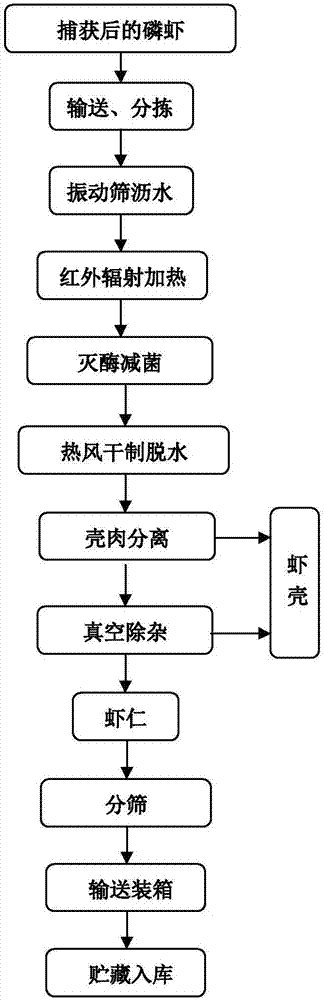

[0038] refer to figure 1 , a ship-borne continuous drying method for fresh and live krill after capture, carried out according to the following steps:

[0039] 1) Cleaning and sorting of caught raw materials: Clean and sort the freshly caught krill with seawater, and place the krill in a vibrating sieve with a vibration frequency of 1050 r / min to remove residual water droplets on the surface of the shrimp.

[0040] 2) Infrared radiation heating: spread the krill treated in step 1) on the conveyor belt into a 7-layer drying box, and use the penetrating power of 1 μm near-infrared radiation for 3.5 minutes, and the central temperature of the shrimp body will reach 75°C. Low-temperature protease and polyphenol oxidase activities are inhibited and begin to be inactivated.

[0041] 3) Hot air drying: make the krill treated in step 2) enter the first stage of hot air drying, the hot air temperature is controlled at 75° C., and the drying wind speed is 1.0 m / s. After 10 minutes, it ...

Embodiment 2

[0047] refer to figure 1 , a kind of fresh and live krill polar ship-borne continuous high-efficiency drying processing method after capture, the sea-borne continuous processing method comprises the following steps:

[0048] 1) Cleaning and sorting of caught raw materials: Clean and sort the freshly caught krill with seawater, and place the krill in a vibrating sieve with a vibration frequency of 1050 r / min to remove residual water droplets on the surface of the shrimp.

[0049] 2) Infrared radiation heating: spread the krill treated in step 1) on the conveyor belt into a 7-layer drying box, and use the medium penetrating power of 20 μm far-infrared radiation for 3.0 minutes, and the central temperature of the shrimp body reaches 72 ° C. Low-temperature protease and polyphenol oxidase activities are inhibited and begin to be inactivated.

[0050] 3) Hot air drying: make the krill treated in step 2) enter the first stage of hot air drying, the hot air temperature is controlled...

Embodiment 3

[0056] refer to figure 1 , a ship-borne continuous drying method for fresh and live krill after capture, the ship-borne continuous drying method is carried out according to the following steps:

[0057] 1) Cleaning and sorting of caught raw materials: Clean the fresh and live krill caught with seawater, sort them, and place the krill in a vibrating sieve with a vibration frequency of 600r / min to remove residual water droplets on the surface of the shrimp body.

[0058] 2) Infrared radiation heating: the krill treated in step 1) is laid flat on the conveyor belt and entered into a 7-layer drying box, using the combination of near-infrared rays with a wavelength of 1 μm with strong penetrating power and far-infrared rays with a wavelength of 290 μm and weak penetrating power, Parallel crossing layout above the conveyor belt, continuous radiation for 2.5 minutes, the central temperature of the shrimp body reached 73°C, and the activity of low-temperature protease and polyphenol o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com