Compound with calcium gluconate grafted aliphatic polyester, method for preparing compound and application thereof

An aliphatic polyester and calcium gluconate technology, which is applied in the fields of polymer chemistry and biomedical materials, can solve problems that need to be improved, and achieve the effects of suitable degradation performance, strong operability, and good repair ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Calcium gluconate anhydrous was processed to 80 μm by a ball mill, dried in vacuum at 70°C for 48 hours, and stored under the protection of argon for future use.

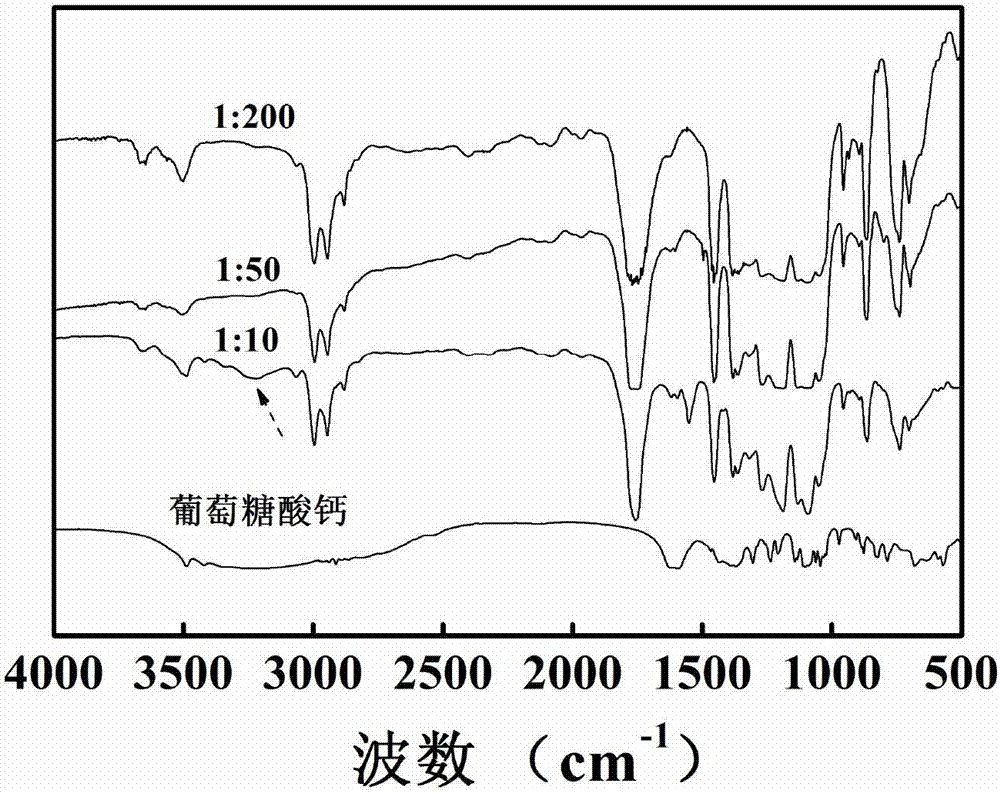

[0059] Under anhydrous and oxygen-free reaction conditions, calcium gluconate, lactide monomer, stannous octoate Sn(Oct) 2 and toluene (refined) were added to the reaction tube, the reaction tube was closed, and the reaction was carried out at 100° C. for 48 hours. After the reaction is complete, the product is dissolved in a solvent such as dichloromethane, isopropanol is settled, and then dried in a vacuum oven at 45° C. for 72 hours. The compound of calcium gluconate grafted aliphatic polyester of the present invention is obtained. Wherein the ratio of stannous octoate and lactide monomer is 2:100 (molar ratio), the weight ratio of calcium gluconate and lactide monomer is 0.5:100, and the volume of described toluene is lactide monomer and 2 times the sum of the weight of calcium gluconate.

Embodiment 2

[0061] Anhydrous calcium gluconate was processed by a ball mill to 100nm, dried in vacuum at 70°C for 48h, and stored under the protection of argon for future use.

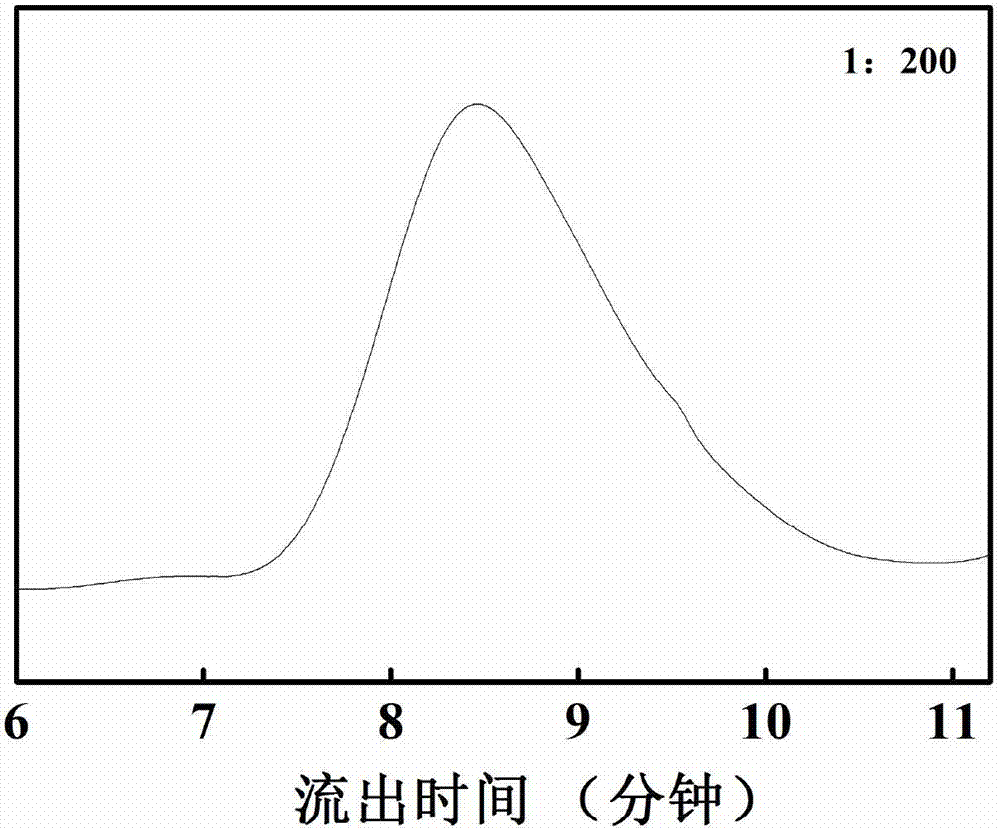

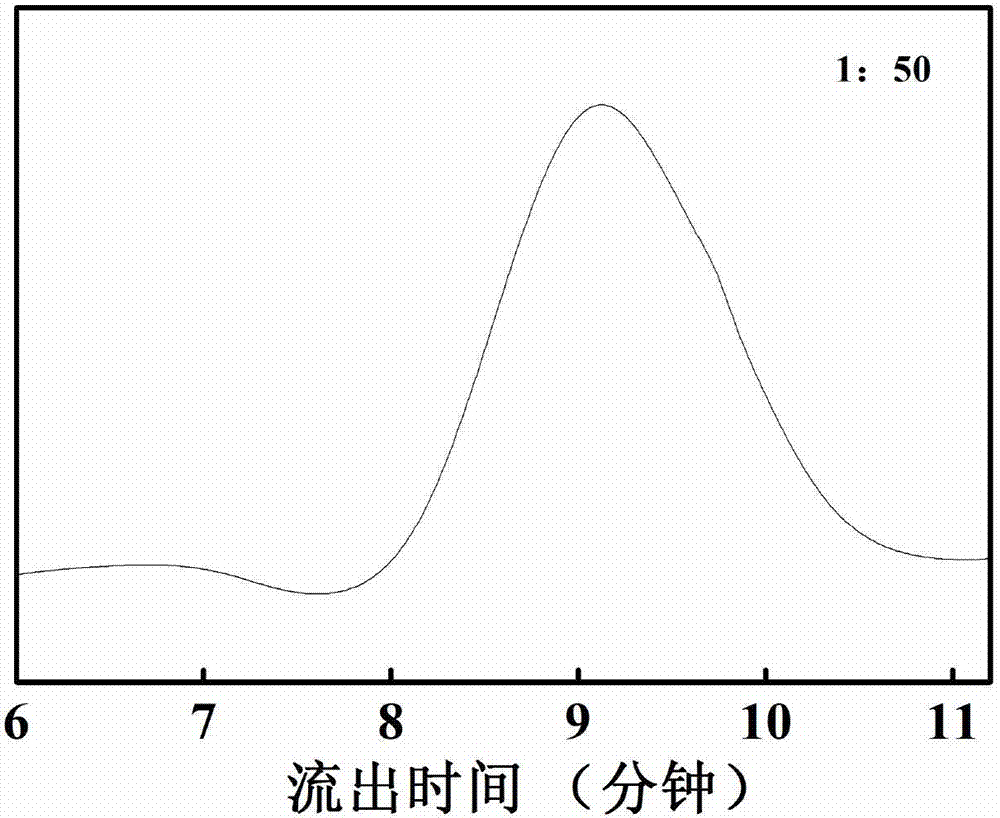

[0062] Under anhydrous and oxygen-free reaction conditions, calcium gluconate, lactide monomer, stannous octoate Sn(Oct) 2 and toluene (refined) were added to the reaction tube, the reaction tube was closed, and the reaction was carried out at 100° C. for 48 hours. After the reaction is complete, the product is dissolved in a solvent such as dichloromethane, isopropanol is settled, and then dried in a vacuum oven at 45° C. for 72 hours. The compound of calcium gluconate grafted aliphatic polyester of the present invention is obtained. Wherein the ratio of stannous octoate and lactide monomer is 2:100 (molar ratio), the weight ratio of calcium gluconate and lactide monomer is 2:100, and the volume of described toluene is lactide monomer and 2 times the sum of the weight of calcium gluconate.

Embodiment 3

[0064] Anhydrous calcium gluconate was processed by a ball mill to 100 μm, dried in vacuum at 70°C for 48 hours, and stored under the protection of argon for future use.

[0065] Under anhydrous and oxygen-free reaction conditions, calcium gluconate, lactide monomer, stannous octoate Sn(Oct) 2 and toluene (refined) were added to the reaction tube, the reaction tube was closed, and the reaction was carried out at 100° C. for 48 hours. After the reaction is complete, the product is dissolved in a solvent such as dichloromethane, isopropanol is settled, and then dried in a vacuum oven at 45° C. for 72 hours. The compound of calcium gluconate grafted aliphatic polyester of the present invention is obtained. Wherein the ratio of stannous octoate and lactide monomer is 2:100 (molar ratio), the weight ratio of calcium gluconate and lactide monomer is 10:100, and the volume of described toluene is lactide monomer and 2 times the sum of the weight of calcium gluconate.

[0066] fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com