A kind of uv curing paint, coating and graphite heat dissipation material

A technology for curing coatings and coatings, which is applied in the direction of heat exchange materials, coatings, polyurea/polyurethane coatings, etc., can solve the problems of not being able to meet the use requirements in the field of heat dissipation, and achieve improved voltage breakdown resistance and fast curing speed , The effect of low curing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

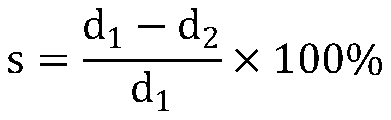

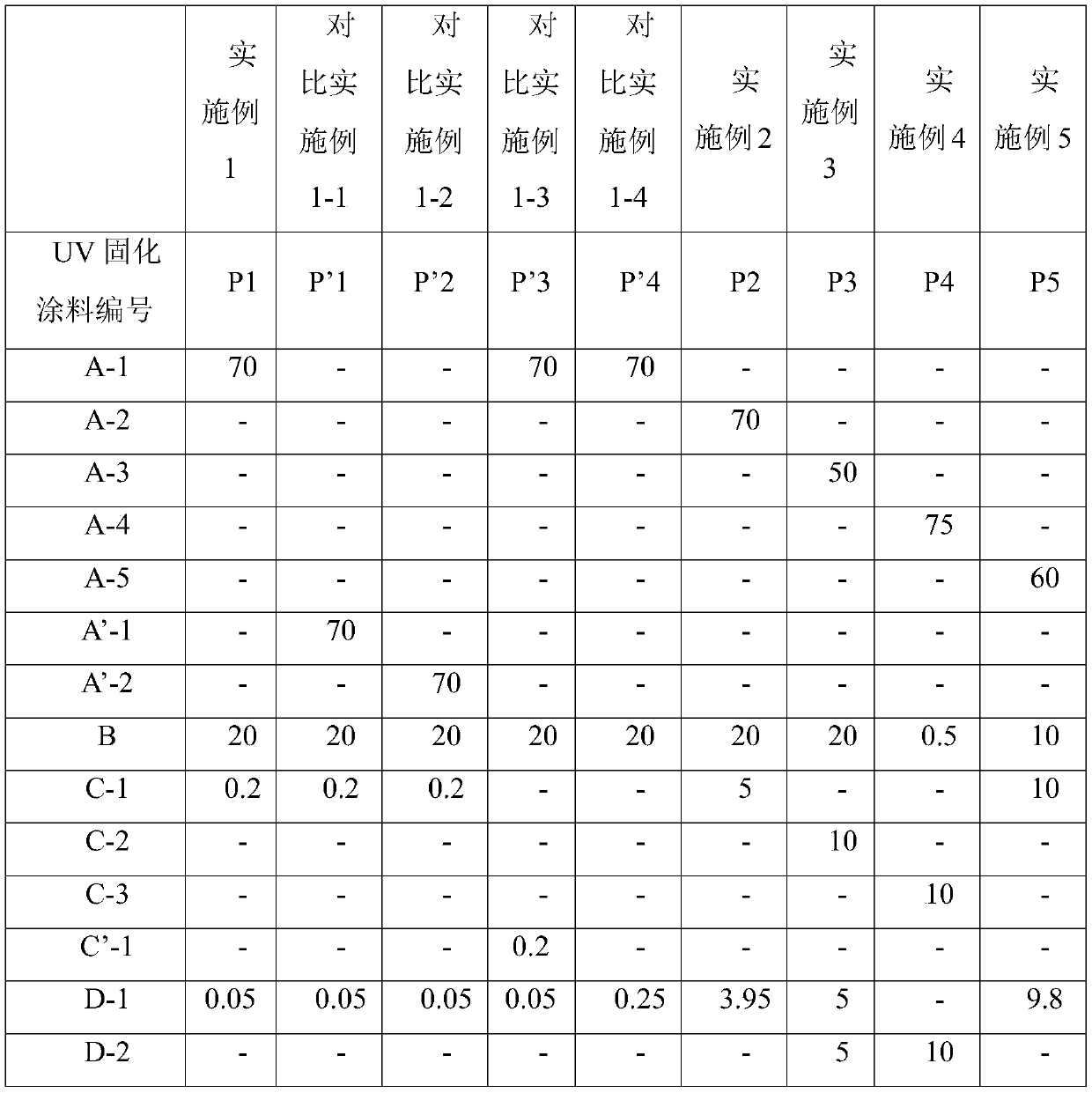

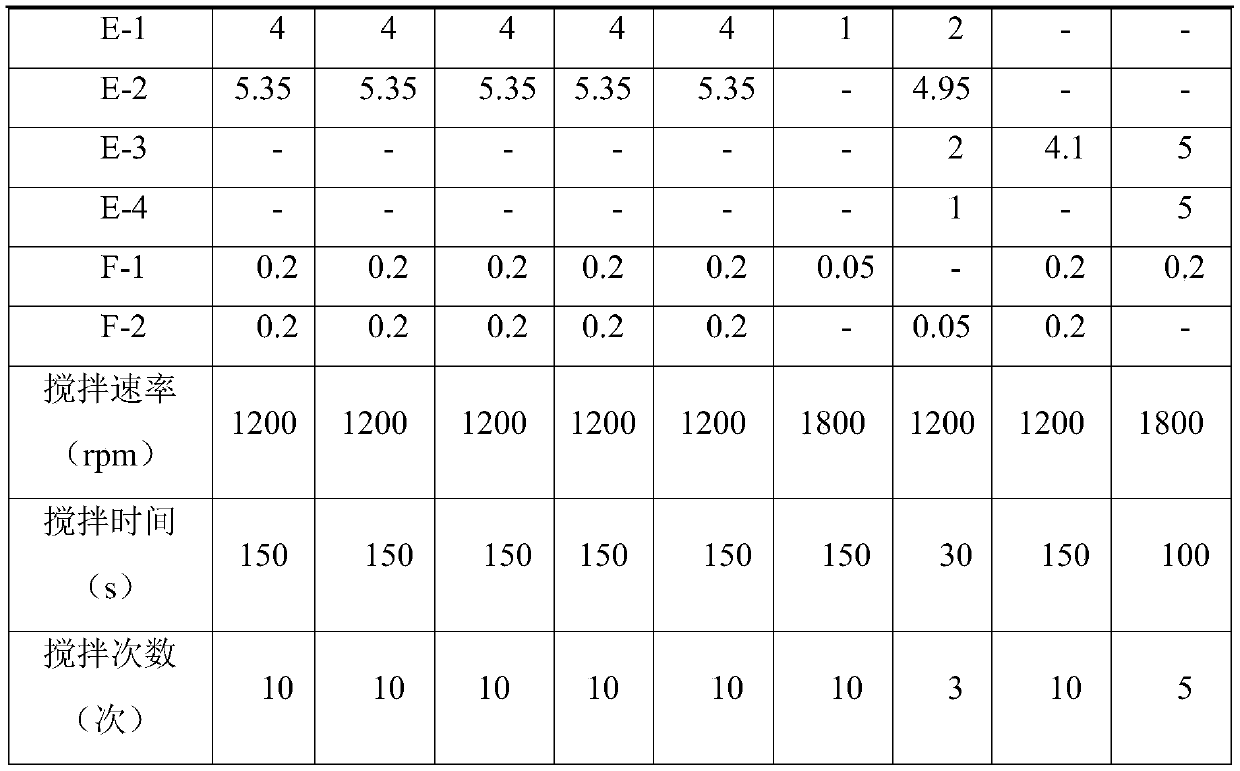

[0052] 1, prepare the embodiment of UV curing coating

[0053] Embodiment 1~5, comparative example 1-1, comparative example 1-2, comparative example 1-3 and comparative example 1-4, prepare UV curable coating by the prescription of table 1 and experimental condition, obtain UV respectively Cured coatings P1~P5, P'1~P'4, the preparation method is as follows:

[0054] Add the PUA oligomer, reactive diluent (1), reactive diluent (2), reactive diluent (3), photoinitiator, and additives into the mixing cup in sequence, and in the planetary mixer at a speed of 1200-1800rpm Stir for 30-150s, and repeat the stirring for 3-10 times to remove air bubbles and obtain a coating with good dispersibility.

[0055] The sample composition of embodiment 1~5, comparative example 1-1, comparative example 1-2, comparative example 1-3 and comparative example 1-4 are as follows:

[0056] A-1 is a bifunctional aliphatic PUA oligomer, and the representative product is U240 of Changxing Chemical Mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com