Pilot-scale production line and process for extracting cellulose nanocrystalline from biomass resources

A technology of biomass resources and cellulose, which is applied in the processing of fiber raw materials, textiles and paper making, etc., to achieve the effects of convenient movement, good test results, and simple and effective design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

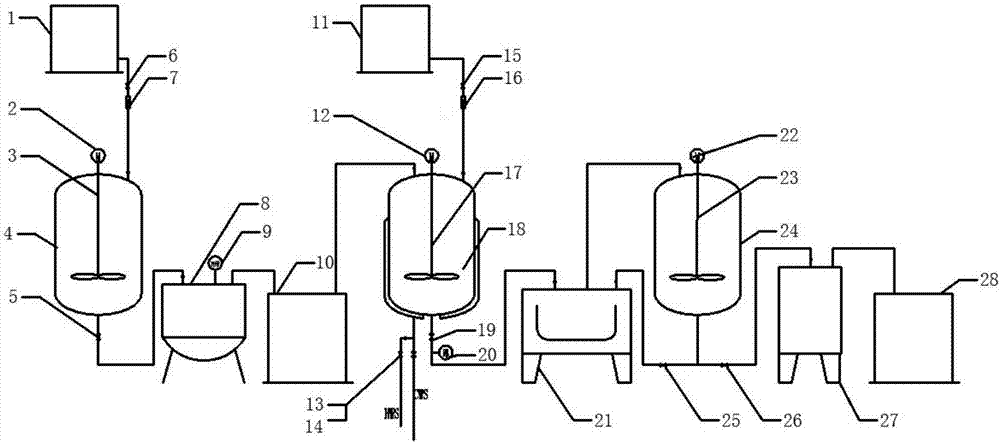

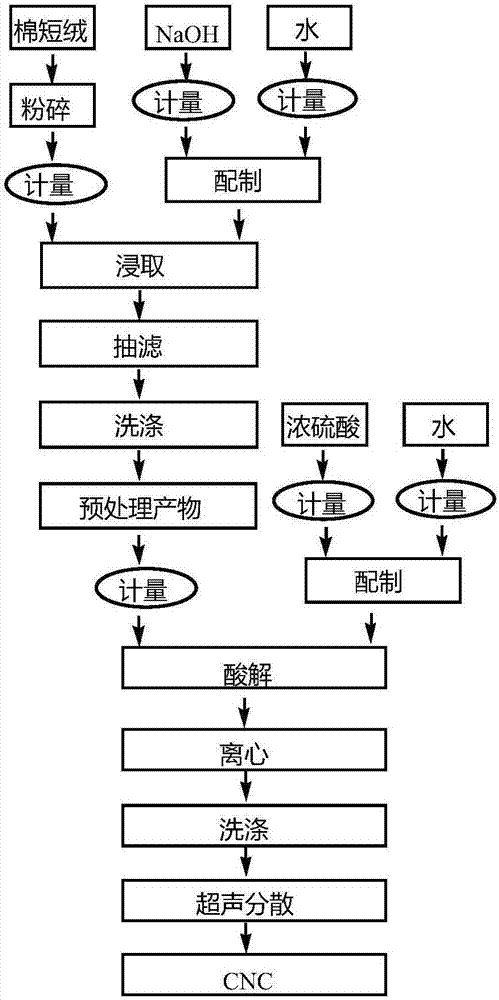

Method used

Image

Examples

Embodiment 1

[0047] (1) According to the existing extraction method of certain cellulose nanocrystals, take cotton linters, sodium hydroxide, concentrated sulfuric acid, water respectively by weight parts, and reserve them for future use;

[0048] (2) Water and sodium hydroxide in (1) are injected into the alkali storage tank, stirred, and mixed with lye of 2% mass concentration; the first discharge valve is closed, and the above-mentioned (1) cotton linters and 1 part and 20 parts of sodium hydroxide solution are added to the alkali leaching reaction kettle through the feed port, and the alkali leaching stirring motor is turned on for stirring. While stirring, the alkali leaching is carried out for 12 hours;

[0049] (3) Open the first discharge valve, pass the product soaked in (2) medium alkali into a vacuum filter, and filter and wash until it is nearly neutral to obtain the purified product;

[0050] (4) inject water and sulfuric acid in (1) into the sulfuric acid storage tank, stir, ...

Embodiment 2

[0056] (1) According to the existing extraction method of certain cellulose nanocrystals, take ascidian powder, potassium hydroxide, concentrated sulfuric acid, water respectively by weight, and keep it for subsequent use;

[0057] (2) Inject the water and potassium hydroxide in (1) into the alkali storage tank, stir, and prepare lye with a mass concentration of 5%; weigh 1 part of ascidian powder in the above (1), and pass 30 parts of potassium hydroxide solution through Add the alkali leaching reaction kettle to the feed port, turn on the alkali leaching stirring motor to stir, and while stirring, alkali leaching for 40 hours;

[0058] (3) Open the first discharge valve, pass the product after (2) medium alkali immersion into vacuum suction filter, suction filter, wash to neutrality and be configured as 300 parts of suspension; Add 5 parts of glacial acetic acid and 10 parts Parts of sodium hypochlorite solution, repeated three times until the suspension was bleached to whit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com