Indoor simulation test device and method for deck asphalt laying bulging formation

A simulation test and asphalt pavement technology, applied in the direction of material inspection products, etc., can solve problems such as single simplification, deviation, and difficulty in mechanical loading simulation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further explained below in combination with specific embodiments and accompanying drawings.

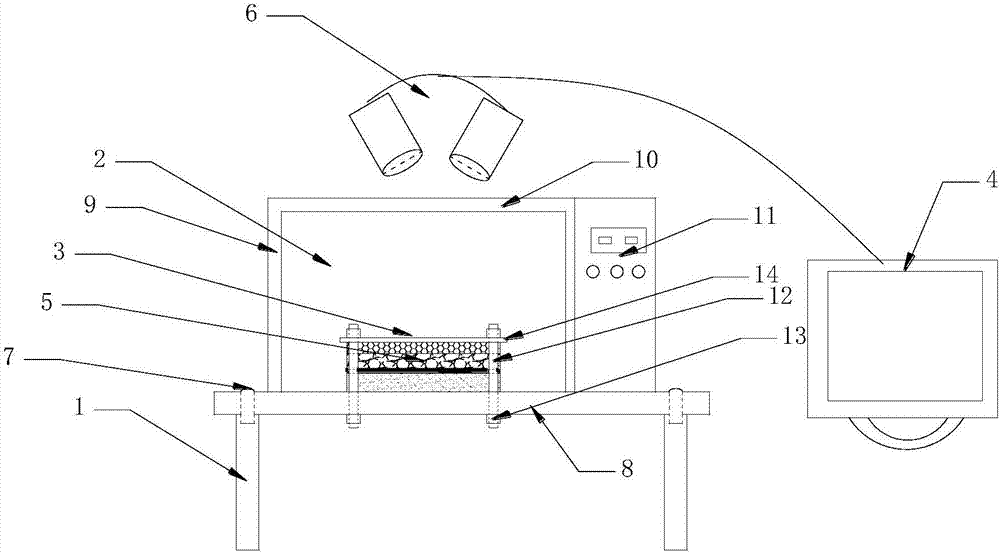

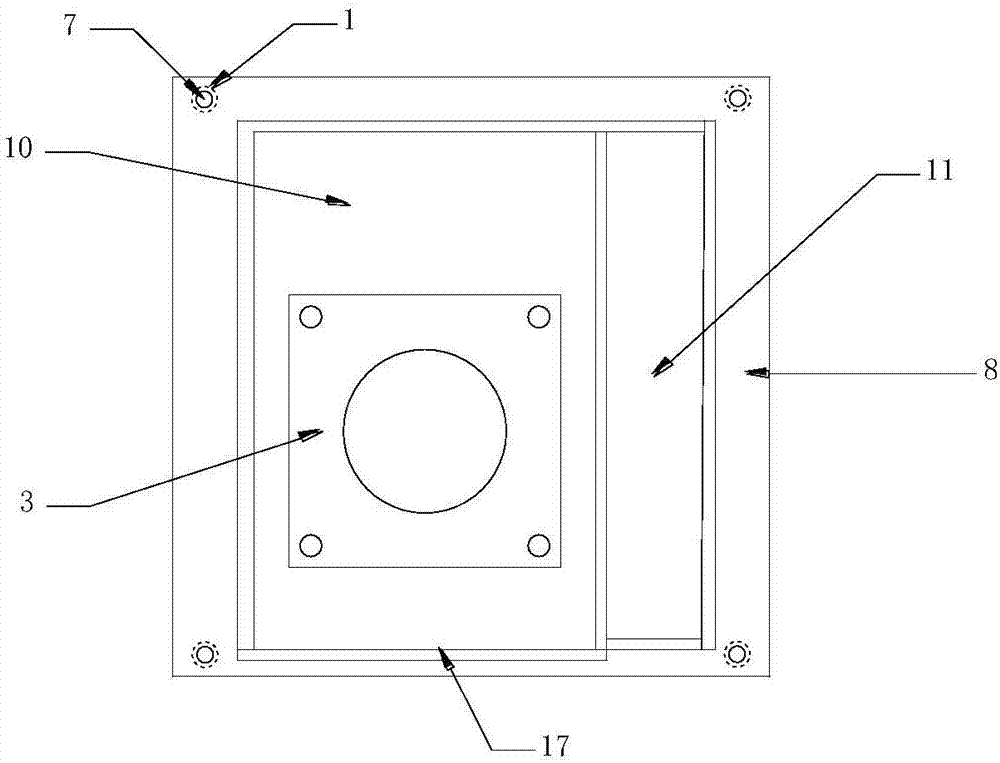

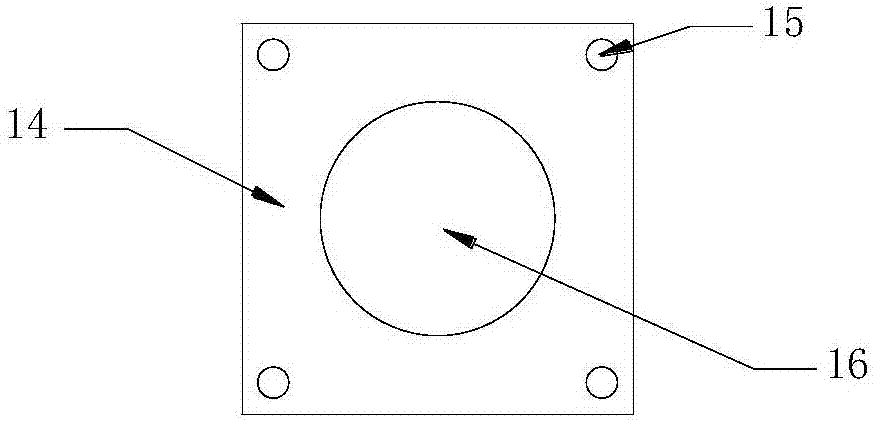

[0036] see figure 1 and figure 2 , the device of the present invention includes a support frame 1 , an environmental chamber 2 , a specimen fixing frame 3 and an MTI-3D structural deformation measurement system 4 . The supporting frame 1 is placed on a flat ground, and its function is to support the upper assembly of the whole device, and support the camera frame including the environmental chamber 2, the specimen fixing frame 3, the specimen 5, and the camera 6. The support frame 1 is composed of four rigid cylinders, and the top of the cylinder is provided with a threaded groove. Through the connection between the bolt 7 and the threaded groove, the support frame 1 is fixed to the bottom plate 8 of the environmental chamber 2, and then the support frame 1 is connected to the upper component. supporting role.

[0037] The environmental chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com