Method for preparing boron carbon nitride nanosheets from graphene and boron nitride nanosheets (BNNSs)

A nanosheet and graphene technology, applied in the field of BCN nanomaterial preparation, can solve the problems of high experimental temperature, inability to achieve mass preparation of BCN nanosheets, difficult control of experimental process, etc., achieving easy research, environmental protection, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Weigh graphene 0.1g, BNNSs 0.1g, both molar percentages are 50%:50%. Put them together in a mortar and grind them evenly.

[0025] (2) Transfer the well-mixed mixture to a ceramic boat and put it into a tube furnace. Under the protection of a nitrogen atmosphere, the temperature was raised to 800° C. at a rate of 5° C. / min and kept for 2 hours.

[0026] (3) After the temperature dropped to room temperature, the product was taken out and placed in a muffle furnace, set at 500°C, and kept at a heating rate of 5°C / min for 6 hours.

[0027] (4) After the product is cooled to room temperature, the product is cleaned with ethanol and dried to obtain BCN nanosheets.

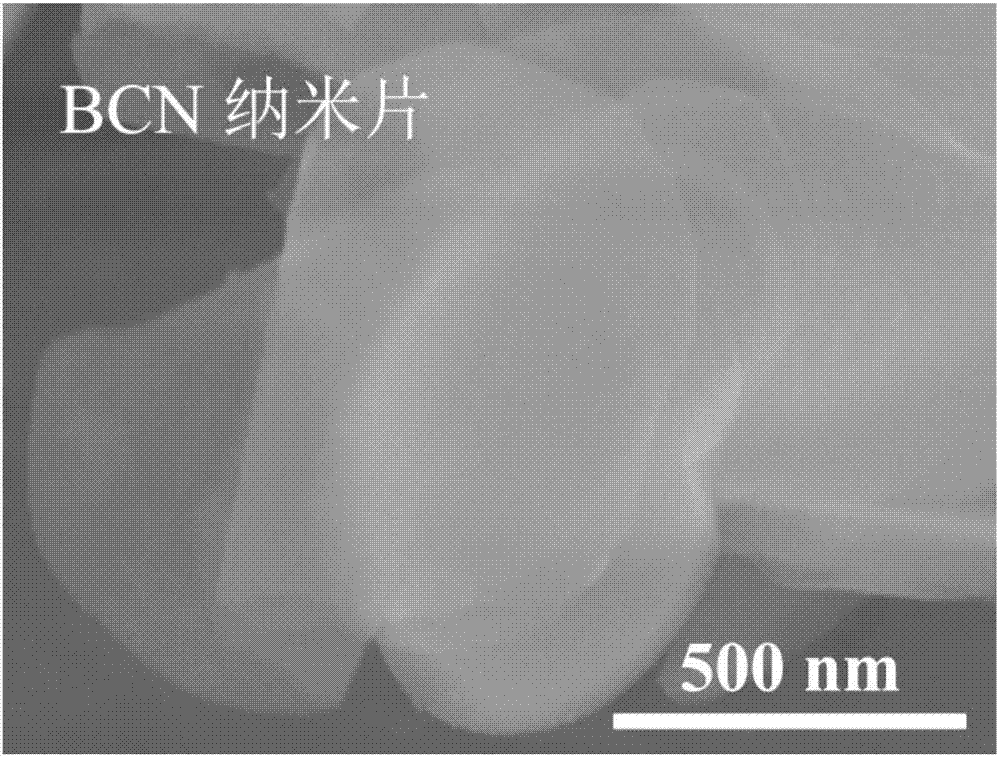

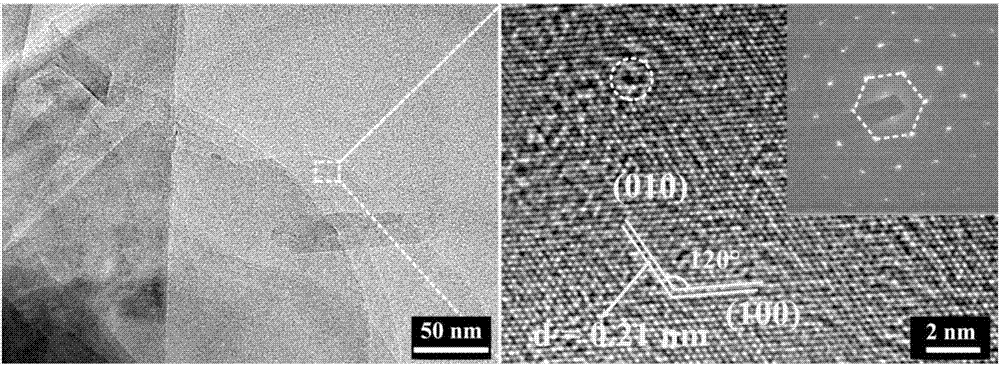

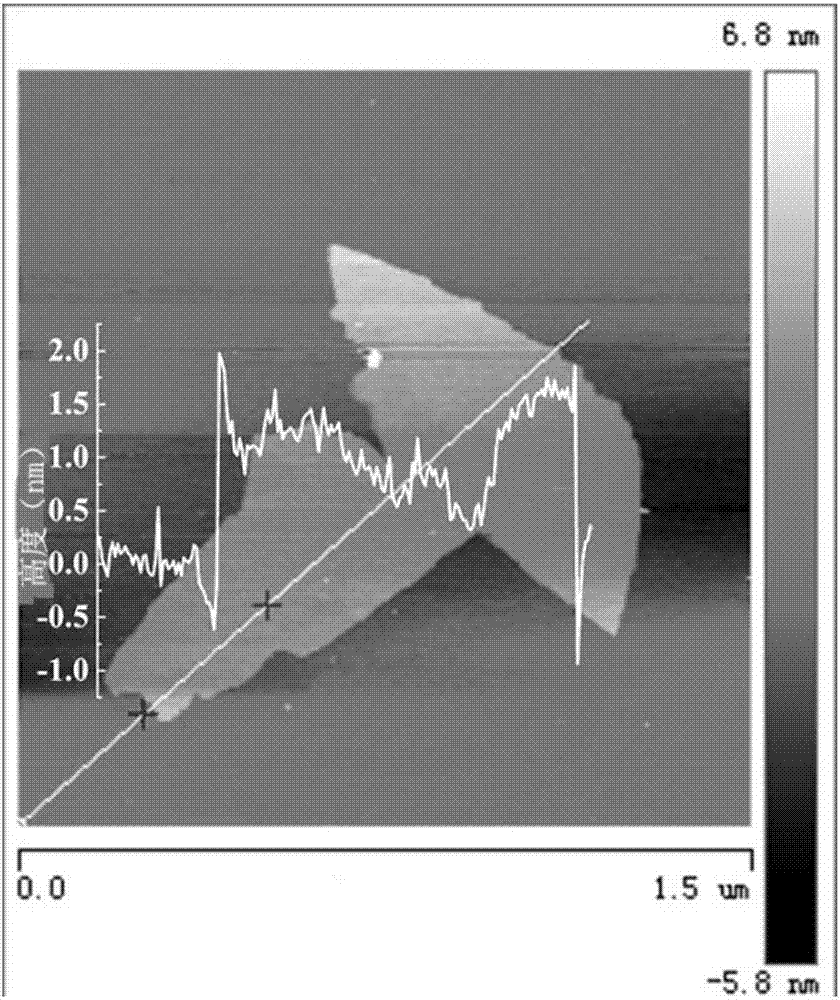

[0028] The scanning electron microscope picture of the BCN nanosheet prepared in the present embodiment is as follows figure 1 As shown, the transmission electron microscope picture is shown as figure 2 As shown, the atomic force microscope as image 3 As shown, the infrared spectra of BCN nanosheets an...

Embodiment 2

[0030] As described in Example 1, the difference is: 0.01 g of graphene and 0.99 g of BNNSs in step (1). The molar percentage of the two is 1%:99%.

Embodiment 3

[0032] As described in Example 1, the difference is: 0.99g of graphene and 0.01g of BNNSs in step (1). The molar percentage of the two is 99%: 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com