Water-erosion-proof plugging agent and preparation method and application thereof

A technology of plugging agent and anti-scour, applied in the field of oil drilling, can solve the problems of strong cohesion of the lost formation, high pressure bearing strength, erosion of the lost circulation agent, etc., and achieves effective plugging of lost channels and high pressure bearing strength. , the effect of stable state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

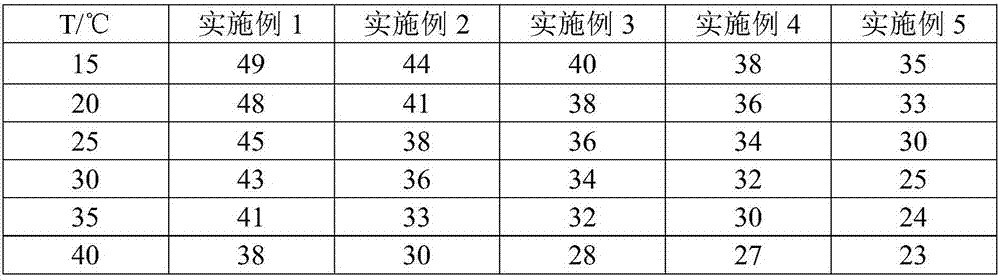

Examples

Embodiment 1

[0032] The waterproof erosion plugging agent of the present embodiment comprises the following components in parts by weight:

[0033] Solid water glass powder: 35 parts by weight

[0034] Acrylate: 8 parts by weight

[0035] Grade G cement: 30 parts by weight

[0036] Sodium hydroxide: 0.5 parts by weight

[0037] Cement early strength agent: 0.2 parts by weight.

[0038] The waterproof erosion plugging agent of the present embodiment is prepared as follows:

[0039] 1) In parts by weight, 35 parts by weight of solid water glass powder is added to 140 parts by weight of water at 80° C., fully stirred and hydrated under a pressure of 5 MPa to make the first aqueous solution;

[0040] 2) Mix 30 parts by weight of grade G cement, 0.5 parts by weight of sodium hydroxide, and 0.2 parts by weight of cement reinforcing agent to obtain the second part of the mixture.

[0041] 3) Add 8 parts by weight of acrylate to 20 parts by weight of water at room temperature and normal press...

Embodiment 2

[0044] The waterproof erosion plugging agent of the present embodiment comprises the following components:

[0045] Solid water glass powder: 35 parts by weight

[0046] Acrylate: 10 parts by weight

[0047] Grade G cement: 30 parts by weight

[0048] Sodium hydroxide: 0.5 parts by weight

[0049] Cement early strength agent: 0.2 parts by weight.

[0050] The waterproof erosion plugging agent of the present embodiment is prepared as follows:

[0051] 1) Add 35 parts by weight of solid water glass powder to 140 parts by weight of water at 80° C., fully stir and hydrate under a pressure of 5 MPa to prepare the first aqueous solution;

[0052]2) Mix 30 parts by weight of grade G cement, 0.5 parts by weight of sodium hydroxide, and 0.2 parts by weight of cement reinforcing agent to obtain the second part of the mixture.

[0053] 3) Add 10 parts by weight of acrylate to 25 parts by weight of water at room temperature and normal pressure, fully stir, and thoroughly emulsify to ...

Embodiment 3

[0056] The waterproof erosion plugging agent of the present embodiment comprises the following components:

[0057] Solid water glass powder: 38 parts by weight

[0058] Acrylate: 10 parts by weight

[0059] Grade G cement: 50 parts by weight

[0060] Sodium hydroxide: 0.7 parts by weight

[0061] Cement early strength agent: 0.4 parts by weight.

[0062] The waterproof erosion plugging agent of the present embodiment is prepared as follows:

[0063] 1) Add 38 parts by weight of solid water glass powder to 152 parts by weight of water at 100° C., fully stir and hydrate under a pressure of 6 MPa to prepare the first aqueous solution;

[0064] 2) Mix 50 parts by weight of grade G cement, 0.7 parts by weight of sodium hydroxide, and 0.4 parts by weight of cement reinforcing agent to obtain the second part of the mixture.

[0065] 3) Add 10 parts by weight of acrylate to 25 parts by weight of water at room temperature and pressure, fully stir and thoroughly emulsify to make t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com