Disposable graphene-butadiene-acrylonitrile rubber gloves and preparation method thereof

A graphene and nitrile rubber technology, applied in the field of latex gloves, can solve the problems of easy breeding of a large number of bacteria, inability to essentially eliminate the use of bacteria, and inability to meet performance requirements, etc., to improve the life of gloves and the antibacterial effect. Effect of method optimization, breaking strength and elongation at break improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

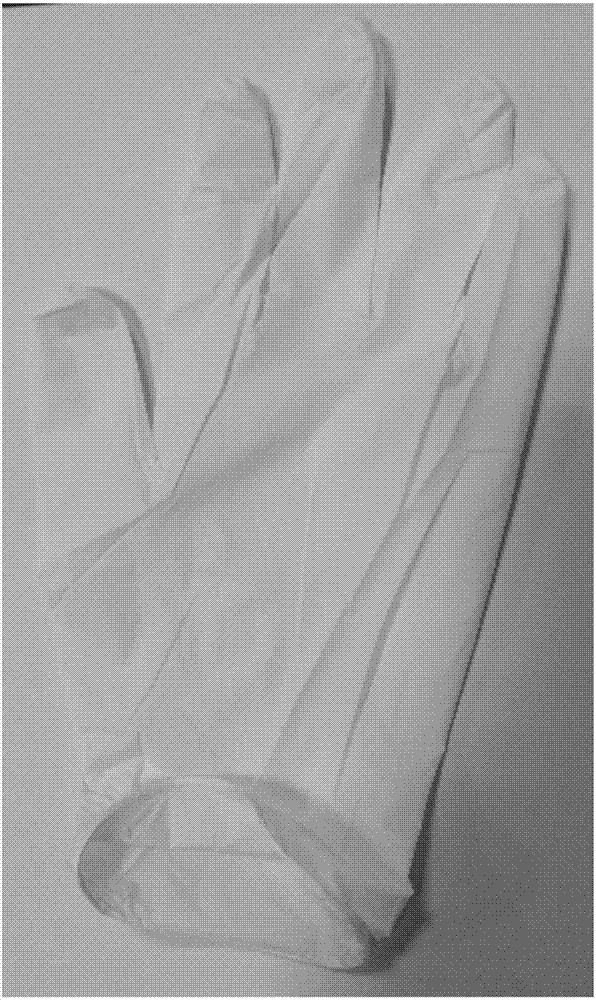

[0043] Embodiment 1-3 provides a kind of graphene-acrylonitrile-butadiene rubber compound shown in table 1 respectively as the technical scheme that raw material carries out disposable graphene-acrylonitrile-butadiene rubber glove preparation, and concrete steps are as follows (please refer to figure 1 ):

[0044] Step 1, prepare raw materials according to the parts by weight described in Table 1; raw materials are added under the condition of its aqueous solution;

[0045] Step 2, adding the alkali into the nitrile latex, carrying out alkalization treatment to the nitrile latex; in this step, the pH of the nitrile latex after the alkali (potassium hydroxide) treatment is more than 9;

[0046] Step 3, adding auxiliary components to the nitrile latex after the alkalization treatment, and grinding; in this step, the number of times of grinding is 2 times;

[0047] Step 4, adding graphene, surfactant, defoamer to carry out pre-crosslinking in the nitrile latex after described gr...

Embodiment 4

[0055] The preparation of embodiment 4 disposable graphene / nitrile composite gloves

[0056] Embodiment 4 provides a kind of graphene-nitrile rubber compound shown in table 2 as raw material to carry out the technical scheme of disposable graphene-nitrile rubber gloves preparation, concrete steps are as follows:

[0057] Step 1, prepare materials according to the parts by weight described in Table 2; raw materials are added in aqueous solution state;

[0058] Step 2, use 1.5 parts of ammonia water to configure a certain proportion of alkali aqueous solution to adjust the pH of the latex;

[0059] Step 3, add auxiliary components, stir evenly, add 2.6 parts of grinding material and grind in a grinder for 3 times;

[0060] Step 4, add 0.01 part of graphene and carboxyl nitrile latex, antifoaming agent to carry out pre-crosslinking reaction, in this step, the condition of pre-crosslinking is 60 degrees Celsius, 12 hours; Simultaneously, add 0.001 part of surfactant;

[0061] St...

Embodiment 5

[0066] The preparation of embodiment 5 disposable graphene-nitrile rubber gloves

[0067] Embodiment 5 provides a kind of graphene-nitrile rubber compound shown in table 2 as raw material to carry out the technical scheme of disposable graphene-nitrile rubber gloves preparation, concrete steps are as follows:

[0068] Step 1, prepare materials according to the parts by weight described in Table 2; raw materials are added in aqueous solution state;

[0069] Step 2, configure the alkali solution of a certain proportion with 1.5 parts of ammoniacal liquor and potassium hydroxide mixed alkali to regulate the pH of latex;

[0070] Step 3, add auxiliary components, add 2.6 parts of grinding material and grind 3 times in the grinder;

[0071] Step 4, add another portion of graphene, surfactant, and defoamer to pre-crosslink for 12 hours at 60 degrees Celsius.

[0072] Step 5: After acid washing, water washing and alkali washing of the hand model in sequence, the hand model is dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com