Irradiation crosslinking wearing-resistant low-torque low-smoke halogen-free flame-retardant cable sheath material for nuclear power station cable and preparation method and cable product of material

A technology for nuclear power plant cables and flame-retardant cables, which is applied in the direction of insulated cables, cables, circuits, etc., and can solve the problems of no further development and application, and insufficient variety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

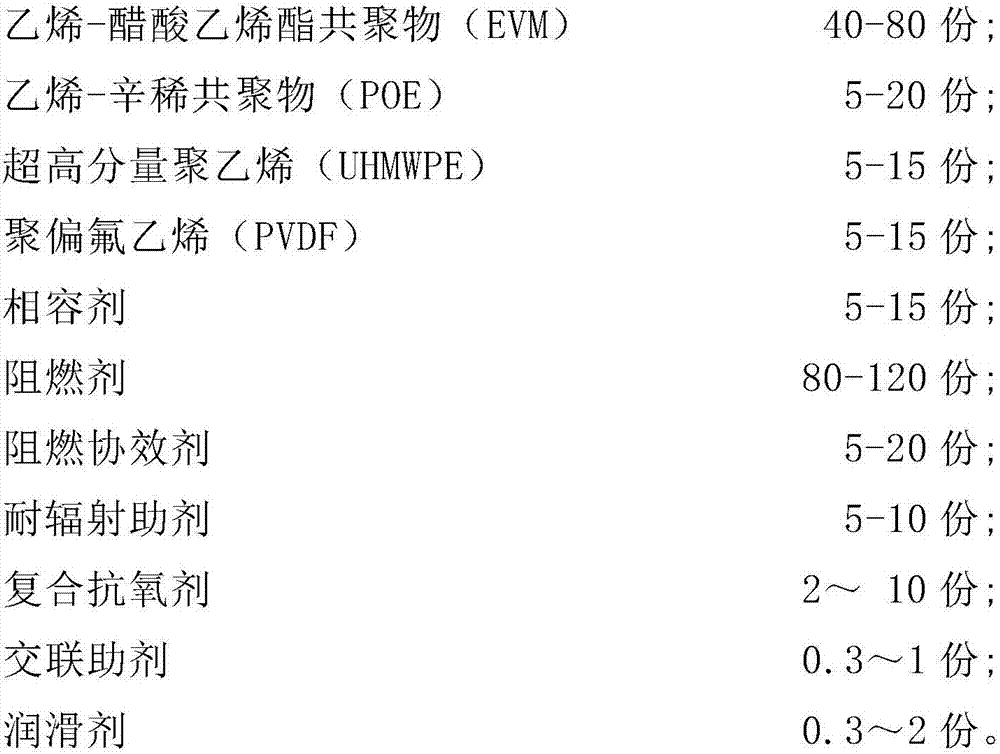

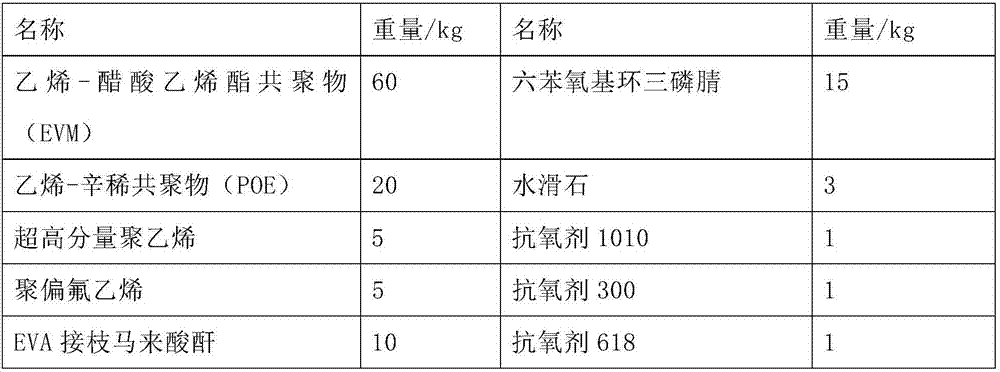

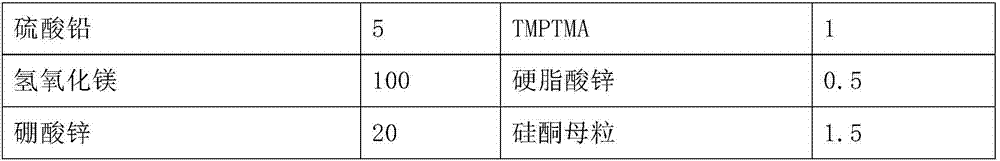

[0063] Each component name and each component parts by weight of embodiment 1 formula are as shown in table 1:

[0064] Table 1

[0065]

[0066]

[0067] Its preparation method is to combine ethylene-vinyl acetate copolymer (EVM), ethylene-octene copolymer (POE), ultra-high-weight polyethylene (UHMWPE), polyvinylidene fluoride (PVDF), compatibilizer, flame retardant , Flame Retardant Synergist, Radiation Resistance Auxiliary, Composite Antioxidant, Crosslinking Auxiliary and Lubricant are mixed, put into high-speed mixer, stir at room temperature for 3-5 minutes, mix evenly, and then add dense The mixer is used for banburying, and the lump material after banburying is mixed. The temperature of each section of the screw is: 190-180°C in the feeding section, 190-180°C in the conveying section, 180-170°C in the melting section, and 180-170°C in the head.

[0068] A performance detection test was performed on the cable material in Example 1, and the performance values a...

Embodiment 2

[0070] Each component name and each component parts by weight of embodiment 2 formula are as shown in table 2:

[0071] Table 2

[0072]

[0073] The preparation method of this embodiment is the same as that of Example 1.

[0074] The product in Example 2 is subjected to a performance detection test, and each performance value is as shown in Table 7 of the performance example.

Embodiment 3

[0076] Each component name and each component parts by weight of embodiment 3 formula are as shown in table 3:

[0077] table 3

[0078]

[0079] The preparation method of this embodiment is the same as that of Example 1.

[0080] The product in Example 3 is subjected to a performance detection test, and each performance value is as shown in Table 7 of the performance example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com