By-pass flow and online scale absorption instrument integrated device

A scale absorber and side flow technology, applied in the field of water treatment, can solve the problems of electrode damage, insignificant scaling phenomenon, a large number of scaling phenomena, etc., and achieve the effects of reducing manpower and material resources, saving costs, and facilitating disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following describes the exemplary embodiments of the present invention in detail with reference to the accompanying drawings; the description of the exemplary embodiments is only for the purpose of illustration, and is by no means limiting the present invention and its application or use.

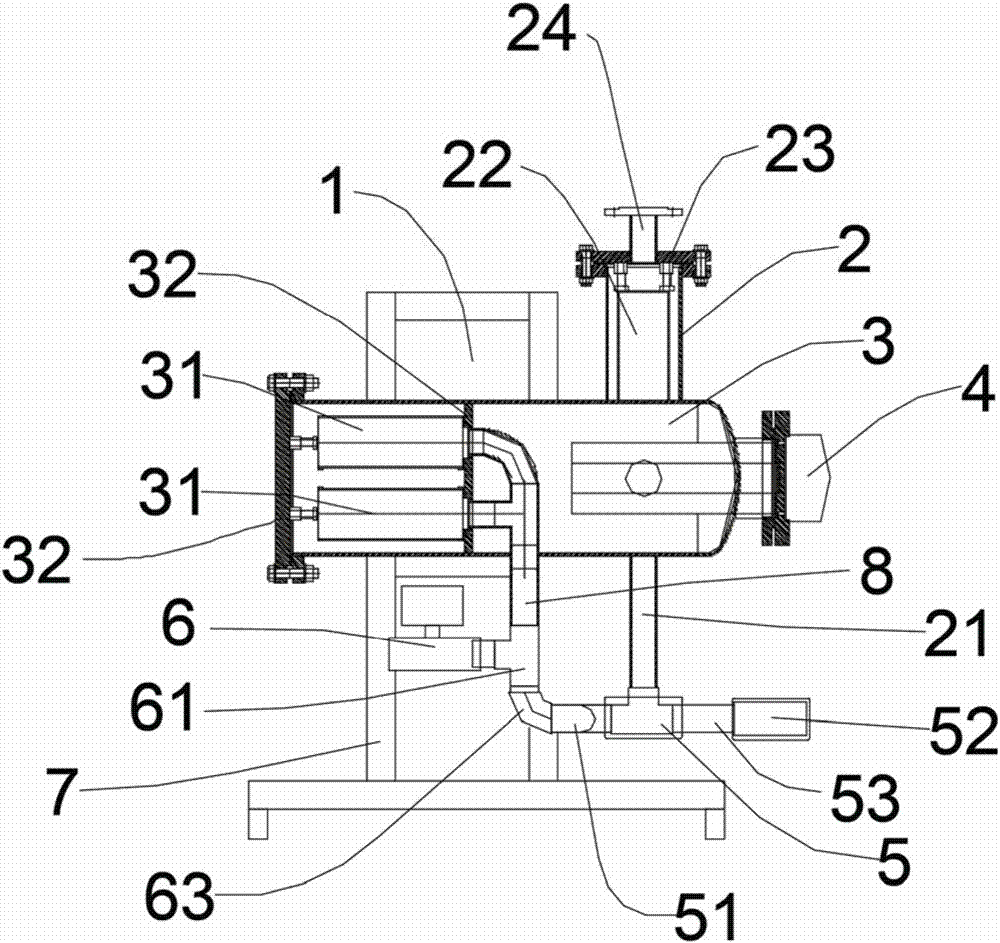

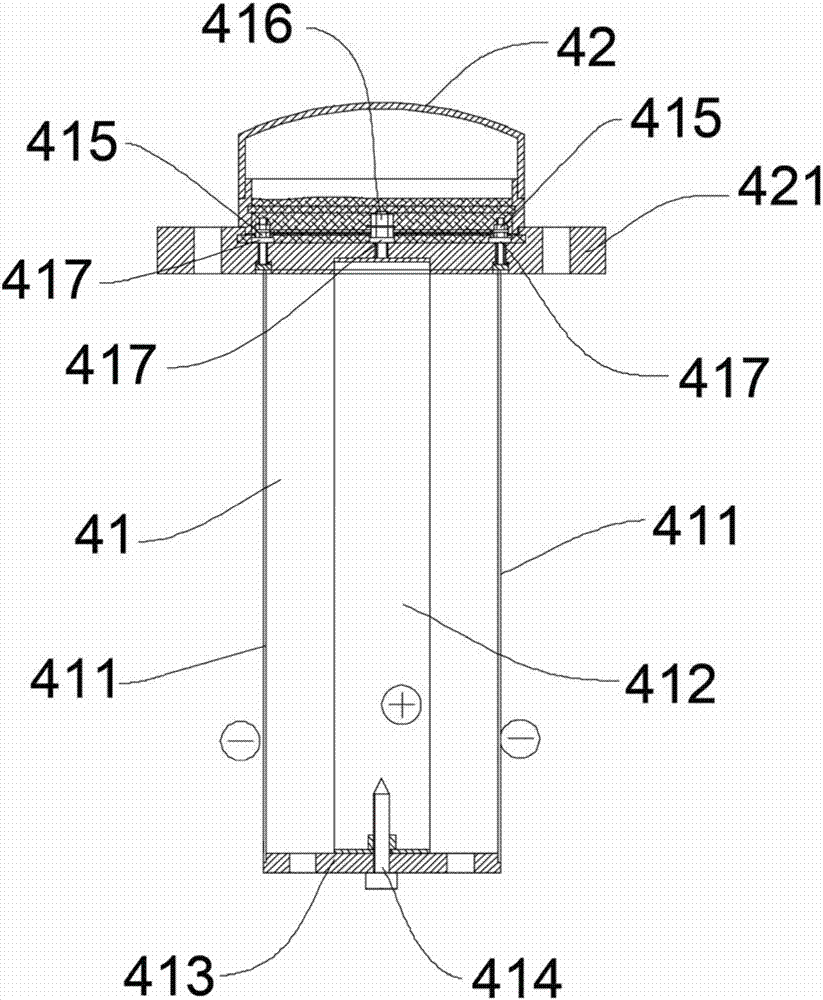

[0022] This embodiment is applied to the air conditioning cooling circulating water system. The original circulating water bypass processor is developed on the basis of the full-flow water processor. The water processor adopts the principle of high-frequency oscillating electric field, according to The water quality is automatically adjusted to process the signal, and side-flow treatment is required to take part of the circulating water for treatment; the products of this technology are suitable for sterilization, algae killing, descaling treatment and removal of suspended solids in the circulating water system; but the open circulating water With the evaporation of water in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com