Novel artificial quartz stone plate and production method thereof

A technology of artificial quartz stone and quartz stone slab, applied in the field of artificial quartz stone, can solve the problems of cracks, poor anti-fouling, insufficient stone density, etc., and achieve the effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

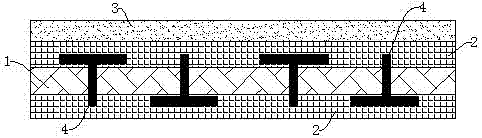

[0027] Embodiment 1, a new type of artificial quartz stone slab, including anti-fouling layer 3, grid layer 2, refractory layer 1 and grid layer 2 in sequence, the refractory layer 1 and grid layer 2 are provided with structural parts 4, The structural members 4 are "⊥" type, and they are scattered in the refractory layer and the grid layer;

[0028] The raw material composition wt% of the refractory layer is: 37% quartz stone sand, 37% quartz stone powder, 8% anticorrosion resin, 0.3% curing agent, 0.7% coupling agent, 5.5% silicon dioxide, 5.5% alumina and 6% rutile titanium dioxide;

[0029] The raw material composition wt% of the grid layer is: 46% quartz stone sand, 46% quartz stone powder, 7% anticorrosion resin, 0.2% curing agent, 0.1% accelerator, 0.7% coupling agent, And use glass fiber mesh as the skeleton;

[0030] The raw material composition wt% of the antifouling layer is: 45% quartz stone sand, 45% quartz stone powder, 7.5% anticorrosion resin, 0.4% curing age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com