Diaphragm with stereoscopic composite structure and preparation method and application thereof

A three-dimensional composite and diaphragm technology, which is applied to structural parts, coatings, electrical components, etc., can solve problems such as unsupported film formation, applications that cannot meet safety requirements, and mechanical performance degradation of the diaphragm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

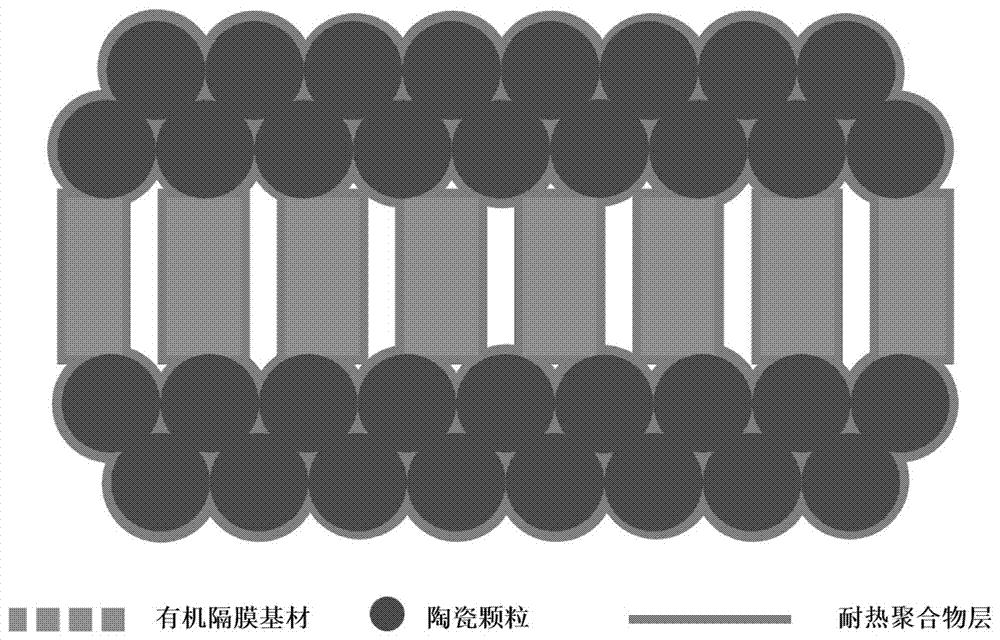

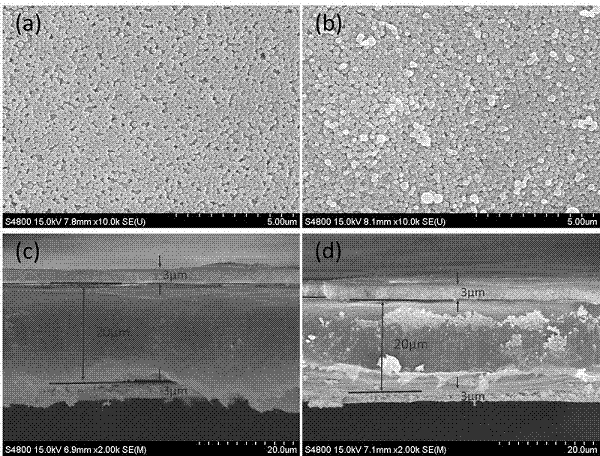

[0061] Example 1: Preparation of a diaphragm with a three-dimensional composite structure and its application in lithium-ion batteries

[0062] Preparation of Ceramic Coated Separators:

[0063] Fully mix silica spherical powder with a particle size of about 300nm, binder (styrene-butadiene rubber (SBR), carboxymethyl cellulose (CMC)) to make a slurry, and its mass ratio is: silica / SBR / CMC=0.95g / 0.03g / 0.02g, the solvent is a water / ethanol mixture with a volume ratio of 1:1, and the mass ratio of liquid to solid is 90:10.

[0064] The prepared slurry was evenly coated on both sides of a commercial polyethylene (PE) separator with an automatic coating machine, and after drying at room temperature, it was dried in vacuum at 50° C. for 10 hours to obtain a silica ceramic coated separator.

[0065] Preparation of a diaphragm with a stereocomposite structure:

[0066] A water-soluble phenolic resin solution with a mass fraction of 1% was prepared by using a water / ethanol mixture ...

Embodiment 2

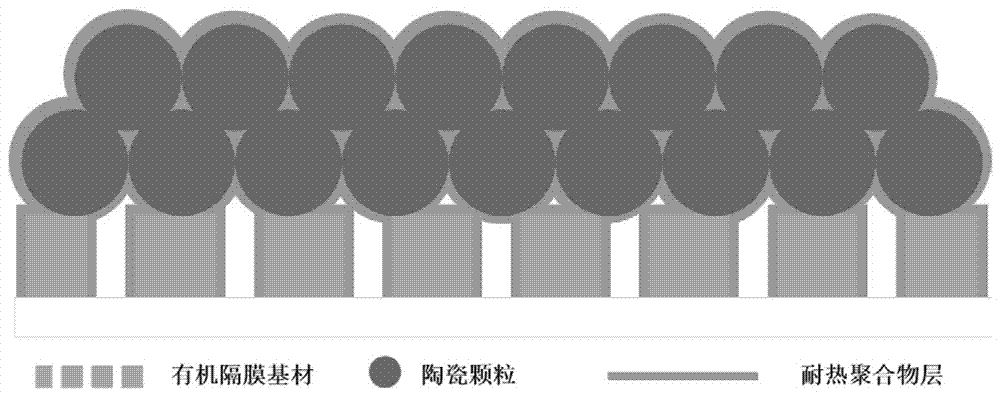

[0071] Example 2: Preparation of a diaphragm with a three-dimensional composite structure and its application in lithium-ion batteries

[0072] Preparation of Ceramic Coated Separators:

[0073] Fully mix alumina powder with a particle size of 300nm and a binder (polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP)) to make a slurry, the mass ratio of which is: alumina / PVDF-HFP=0.9g / 0.1g, the solvent is NMP / acetone mixed solution with a volume ratio of 1:1, and the mass ratio of liquid to solid is 90:10.

[0074] The prepared slurry was evenly coated on one side of a commercial polyethylene (PE) separator with an automatic coating machine, and after drying at room temperature, it was dried in vacuum at 50° C. for 10 hours to obtain an alumina ceramic coated separator.

[0075] Preparation of a diaphragm with a stereocomposite structure:

[0076] A water-soluble phenolic resin solution with a mass fraction of 1% was prepared by using a water / ethanol mixture with a volume r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com