Preparation method and application of trimethyl silicon alkoxide

A technology of trimethylsilanol and potassium trimethylsiliconate, which is applied in the field of preparation of trimethylsiliconate, and can solve problems such as instability of trimethylsilanol, unsuitability for industrial production, and danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

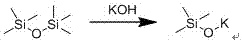

[0020] see figure 1 , the present invention provides a technical solution: a method for preparing trimethylsiliconate, the preparation steps are as follows: put hexamethyldisiloxane and potassium hydroxide into a 10L three-necked bottle, add 10ml of alcohol preparation, Heated to reflux for 48 hours, while separating water with a water separator, cooled, filtered, and dried to obtain white solid potassium trimethylsiliconate. Alcohol preparations used were methanol, ethanol, isopropanol or ethylene glycol. High-content potassium trimethylsilanolate is prepared by using hexamethyldisiloxane (MM), a cheap industrially produced raw material, as a raw material, and heating and refluxing with various catalysts such as potassium hydroxide. These catalysts are all beneficial to the dissolving of potassium hydroxide and the carrying out of the reaction.

[0021] The process has only one step of reaction. Hexamethyldisiloxane and potassium hydroxide are heated and refluxed under cata...

Embodiment 1

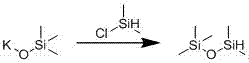

[0023] Such as figure 2 As shown, put 3kg of hexamethyldisiloxane and 560g of potassium hydroxide in a 10L three-necked flask, heat 10ml of methanol, heat to reflux for 48 hours, and simultaneously use a water separator to separate water, cool, filter, and dry to obtain a purity of 91% white solid potassium trimethylsiliconate 0.95kg.

[0024] Take 1.12kg of the obtained potassium trimethylsiliconate in 2L of anhydrous tetrahydrofuran, add 1kg of dimethylchlorosilane dropwise under stirring, and react for 1h at room temperature, filter, concentrate, extract with ether, dry, and concentrate to obtain 1.2kg of pentamethyldisiloxane with a purity of more than 98%.

Embodiment 2

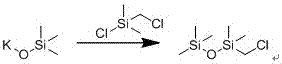

[0026] Such as image 3 As shown, put 3kg of hexamethyldisiloxane and 560g of potassium hydroxide in a 10L three-necked flask, heat 10ml of ethanol, heat to reflux for 48 hours, and simultaneously use a water separator to separate water, cool, filter, and dry to obtain a purity of 90% white solid potassium trimethylsiliconate 0.93kg.

[0027] Take 1.12 kg of the obtained potassium trimethylsiliconate in 2 L of anhydrous tetrahydrofuran, add 1.2 kg of chloromethyl dimethyl chlorosilane dropwise under stirring, and react for 1 h at room temperature, filter, concentrate, extract with ether, and dry , concentrated to obtain 1.8kg of chloromethylpentamethyldisiloxane with a high purity of more than 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com