Self-lubricating treatment method for aero-engine bearing

An aero-engine and processing method technology, applied in the field of friction pair self-lubrication, can solve the problems affecting bearing matching accuracy and support stiffness, limiting machining accuracy, bearing channel wear life, etc., to improve the comprehensive performance of friction reduction and wear resistance, The effect of reducing the surface friction coefficient and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

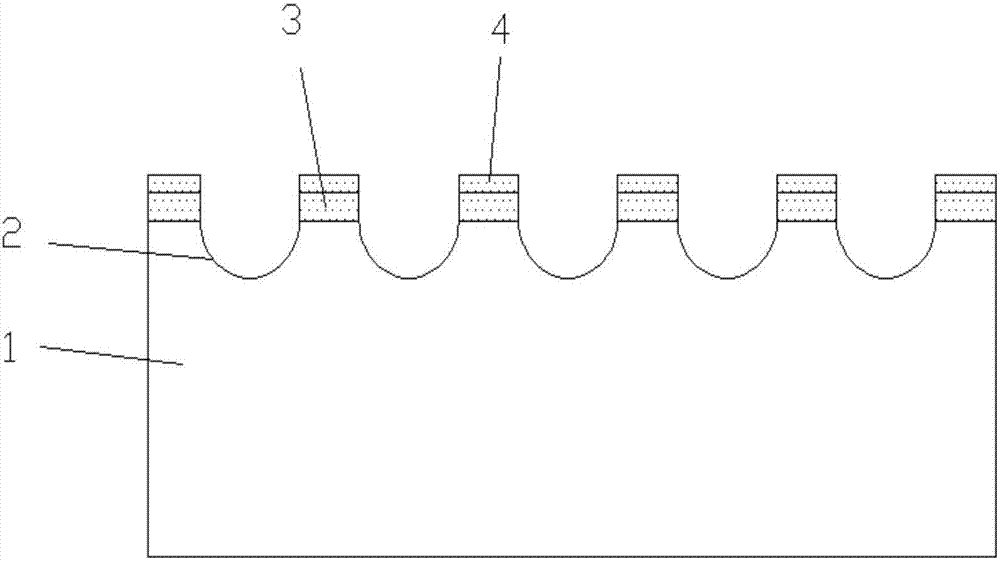

[0026] figure 1 Shown is a schematic diagram of self-lubricating treatment of aero-engine bearings, and the self-lubricating treatment method of aero-engine bearings includes the following steps:

[0027] Step A) For the laser micro-modeling treatment of the aero-engine bearing 1, a diode-pumped Nd:YAG laser processing system is used, the laser wavelength is 532nm, the current intensity is 18.6A, the frequency is 1600Hz, the number of pulses is 4 times, and nitrogen is used as an auxiliary Gas, with a gas pressure of 0.15Mpa, micro-dimples 2 are formed on the rolling or sliding contact parts of the aero-engine bearing 1, and then the surface of the sample is polished with metallographic sandpaper until the slag around the micro-dimples 2 disappears, and the measured surface hardness is still about It is 62-64HRC. Using the WYKO-NT100 three-dimensional measuring instrument for surface micro-geometric topography produced by Veeco, the diameter of a single pit 2 in the sample is...

Embodiment 2

[0033]The self-lubricating treatment method of the aero-engine bearing comprises the following steps:

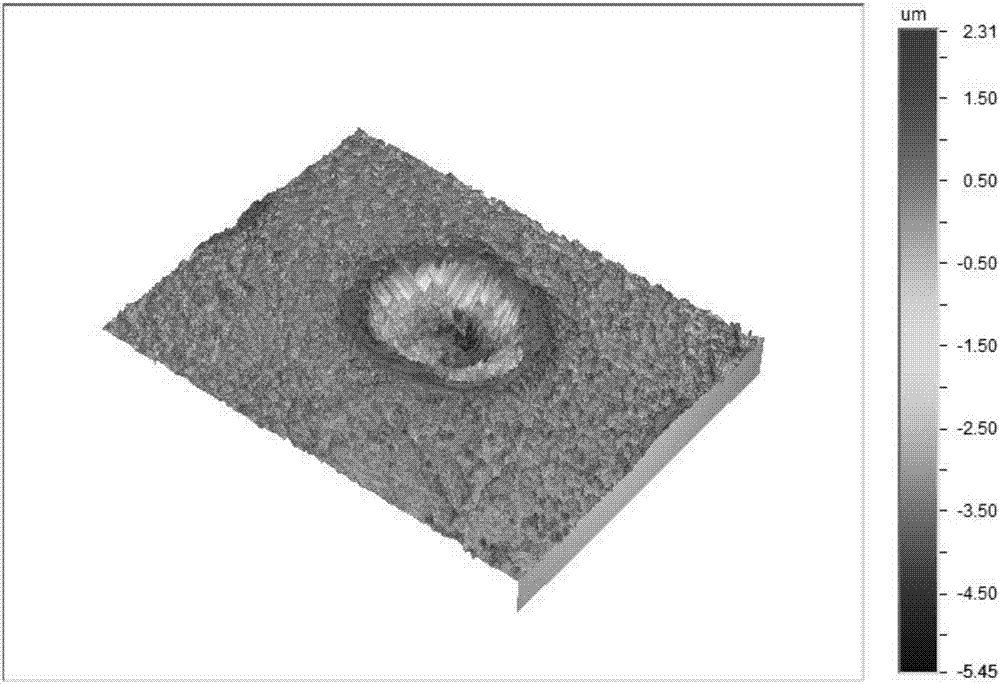

[0034] Step A) For the laser micro-modeling treatment of the aero-engine bearing 1, a diode-pumped Nd:YAG laser processing system is used, the laser wavelength is 532nm, the current intensity is 16.6A, the frequency is 1600Hz, the number of pulses is 3 times, and nitrogen is used as an auxiliary Gas, with a gas pressure of 0.15Mpa, micro-dimples 2 are formed on the rolling or sliding contact parts of the aero-engine bearing 1, and then the surface of the sample is polished with metallographic sandpaper until the slag around the micro-dimples 2 disappears, and the measured surface hardness is still about It is 62-64HRC. Using the WYKO-NT100 three-dimensional measuring instrument for surface microscopic geometric topography produced by Veeco, the diameter of a single pit 2 of the sample is measured to be about 60 μm, the depth is about 4 μm, and the distance between the micro-...

Embodiment 3

[0040] The self-lubricating treatment method of the aero-engine bearing comprises the following steps:

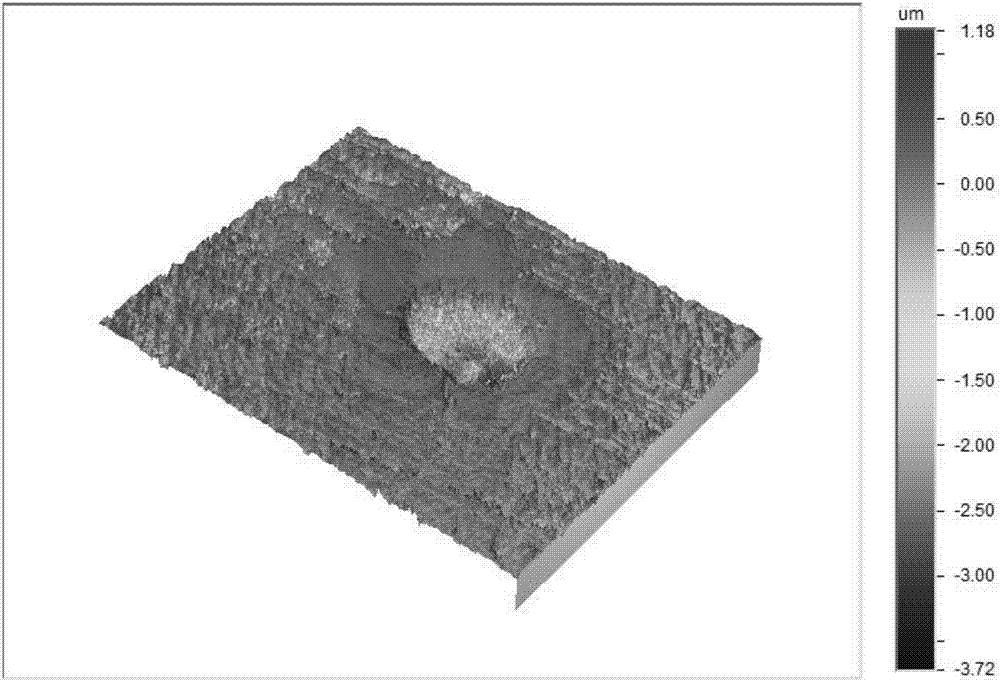

[0041] Step A) For the laser micro-modeling treatment of the aero-engine bearing 1, a diode-pumped Nd:YAG laser processing system is used, the laser wavelength is 532nm, the current intensity is 20A, the frequency is 1600Hz, the number of pulses is 8 times, and nitrogen is used as the auxiliary gas , the gas pressure is 0.15Mpa, micro-dimples are formed on the rolling or sliding contact parts of the aero-engine bearing 1, and then the surface of the sample is polished with metallographic sandpaper until the slag around the micro-dimples 2 disappears, and the measured surface hardness is still about 62 -64HRC. Using the WYKO-NT100 three-dimensional measuring instrument for surface micro-geometric topography produced by Veeco, the diameter of a single pit 2 of the sample is measured to be about 120 μm, the depth is about 10 μm, and the distance between the micro-pit 2 is 220 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com