Tank type heat-storage incinerator

An incinerator and heat storage technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of low processing efficiency, troublesome installation and maintenance, and large equipment volume of the two-chamber heat storage incinerator, and achieve simple structure, Easy installation and maintenance, small equipment size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

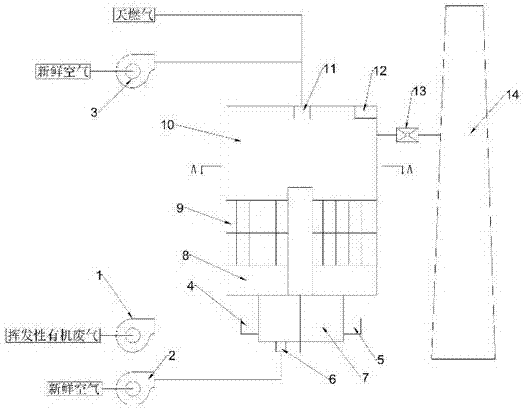

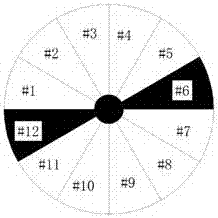

[0020] A tank-type regenerative incinerator, including a system fan 1, a reverse blower 2, a combustion-supporting fan 3, an airflow reversing valve 7, a buffer chamber 8, a regenerator 9, a combustion chamber 10, a burner 11, an electric thermocouple 12, a high temperature Smoke valve 13, chimney 14 and industrial control system. The main body of the tank-type regenerative incinerator is mainly composed of a regenerator 9 and a combustion chamber 10. The regenerator 9 is a cylindrical structure, and the upper and lower ends are not sealed. The inner wall of the steel cylinder is provided with an insulation layer. Evenly divided into 12 independent heat storage spaces #1--#12, each space is equipped with a honeycomb ceramic heat storage body; the combustion chamber 10 is also a cylindrical structure, the upper end is sealed, and the lower end is open. The upper end of the regenerator 9 is butted, the combustion chamber 10 is provided with the burner 11, the thermocouple 12 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com