Self-calibration gas chamber and distributed optical fiber methane sensing system

A distributed optical fiber and sensing system technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of increasing system cost, inability to realize accurate calibration of a single measurement channel, reducing system capacity, etc., and achieve system cost reduction, simple structure, Effect of increasing system capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

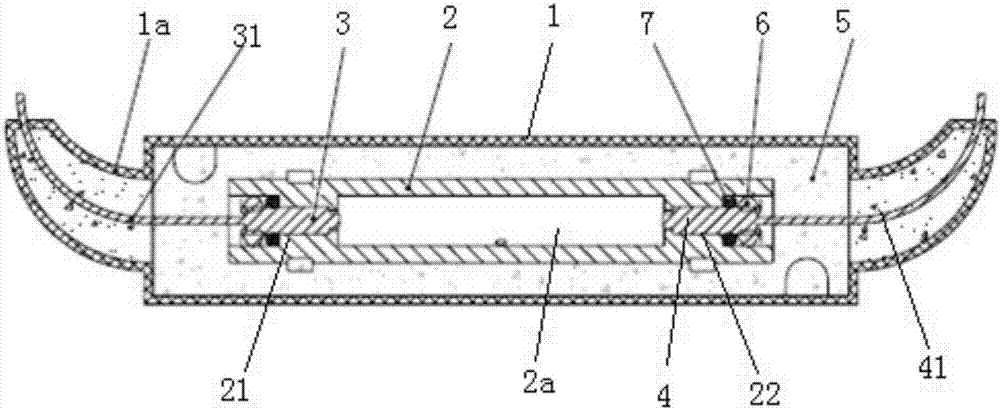

[0023] Such as figure 1 Shown: the self-calibration gas chamber of this embodiment includes a potting box 1 and a shell 2 potted and fixed in the potting box 1, an optical fiber collimator I3 and an optical fiber collimator II4, the shell 2 is provided with There is a gas accommodating cavity 2a for accommodating self-calibration gas and its left and right sides are symmetrically provided with a fixing seat I21 and a fixing seat II22, an optical fiber collimator I3 fixed in the fixing seat I21 and an optical fiber collimator fixed in the fixing seat II22 The pigtails Ⅰ31 of the fiber collimator Ⅰ3 and the pigtails Ⅱ41 of the fiber collimator Ⅱ4 are respectively led out from the fiber outlet 1a on both sides of the potting box 1. The housing 2 is cylindrical, with a Vent; the structure of the fiber collimator Ⅰ3 and the fiber collimator Ⅱ4 are the same, but when in use, the laser beam enters from the fiber collimator Ⅰ3 on one side and exits from the fiber collimator Ⅱ4 on the ot...

Embodiment 2

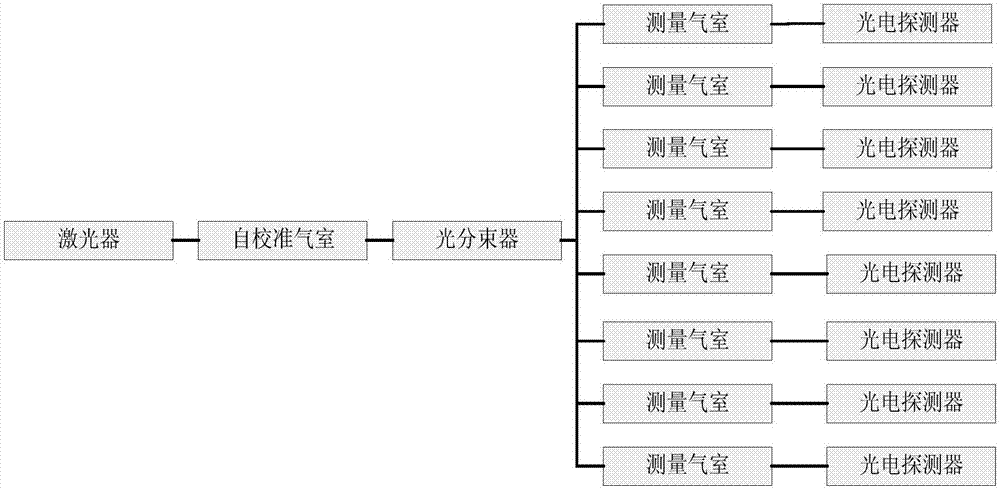

[0040] Such as figure 1 with figure 2 As shown, the distributed optical fiber methane sensing system of this embodiment includes a laser for emitting laser, a self-calibrating gas chamber, an optical beam splitter, and a measurement channel that are sequentially connected along the laser optical path, and at least two measurement channels are arranged in parallel. Each measurement channel includes a measurement gas chamber and a photodetector. The laser beam enters the photodetector after passing the measurement gas chamber; the self-calibration gas chamber includes potting box 1 and potting A housing 2, an optical fiber collimator I3 and an optical fiber collimator II4 are fixed in the potting box 1. The housing 2 is provided with a gas accommodating cavity 2a for accommodating self-calibration gas, and its left and right sides are symmetrically provided with fixing Base Ⅰ21 and holder Ⅱ22, fiber collimator Ⅰ3 fixed in holder Ⅰ21 and fiber collimator Ⅱ4 fixed in holder Ⅱ22 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com