Preparation method for extrusion blow molding of waste

An extrusion blow molding and waste technology, which is applied in the field of waste extrusion blow molding, can solve the problems of complex production process of die-casting molding process base, prone to brittle fracture, high cost, etc., and achieves high cost performance and no secondary pollution. , the effect of short process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

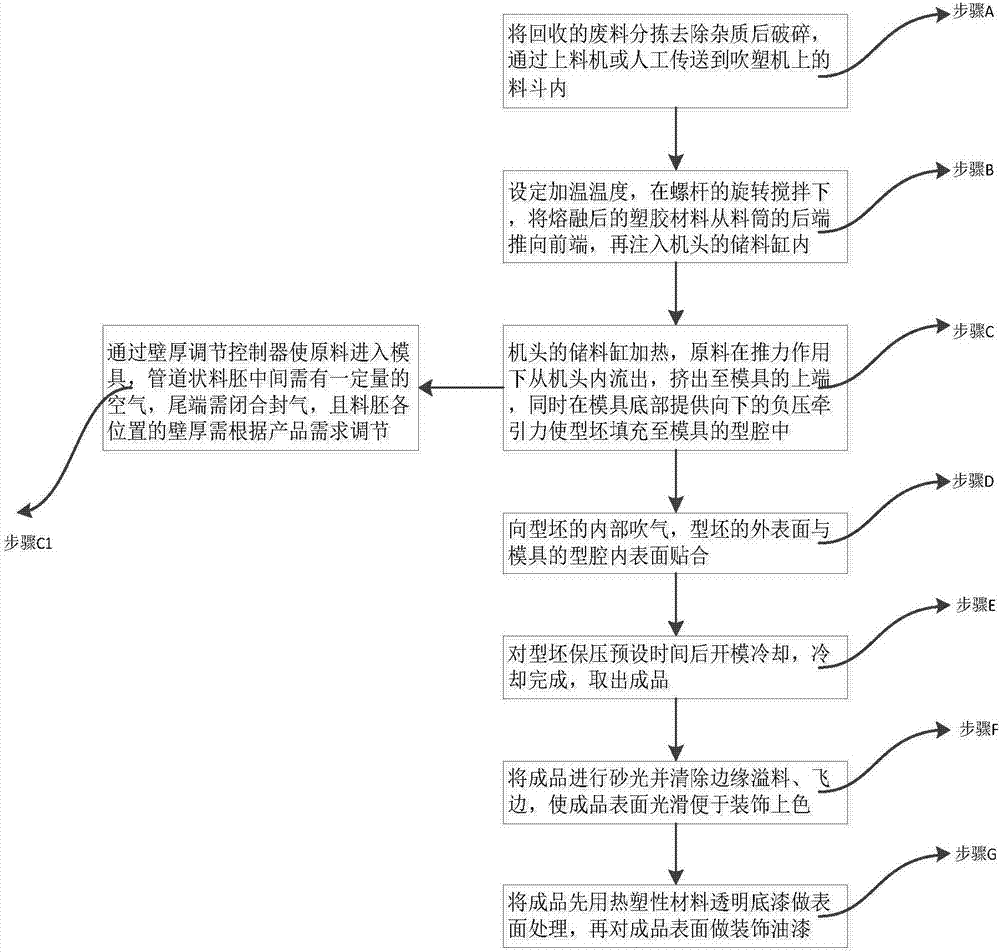

[0027] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. refer to figure 1 , the present invention provides a kind of waste material extrusion blow molding preparation method, comprises the following steps:

[0028] Step A, sorting the recovered waste to remove impurities and crushing to obtain crushed raw materials, which are sent to the hopper on the blow molding machine through a feeder or manually;

[0029] Step B, set the heating temperature, push the melted plastic material from the rear end of the barrel to the front end under the thrust of the screw rotating and stirring, and then inject it into the material storage tank of the machine head;

[0030] Step C, the material storage tank of the machine head is heated up, the raw material from the barrel is kept in a gel state, and under the thrust of the screw, it flows out from the machine head after being heated and kept warm, and extruded to the upper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com