Rotary powder spraying device and upgrading method for ladle slag reforming

A rotating device and modification technology, applied in the field of steelmaking, can solve the problems affecting the vacuum treatment process of the equipment, the adverse effects of the vacuum system, and the production of waste products on the quality of the product, and achieve the effects of avoiding uneven thickness, eliminating flocculent water, and reducing impurities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific embodiment:

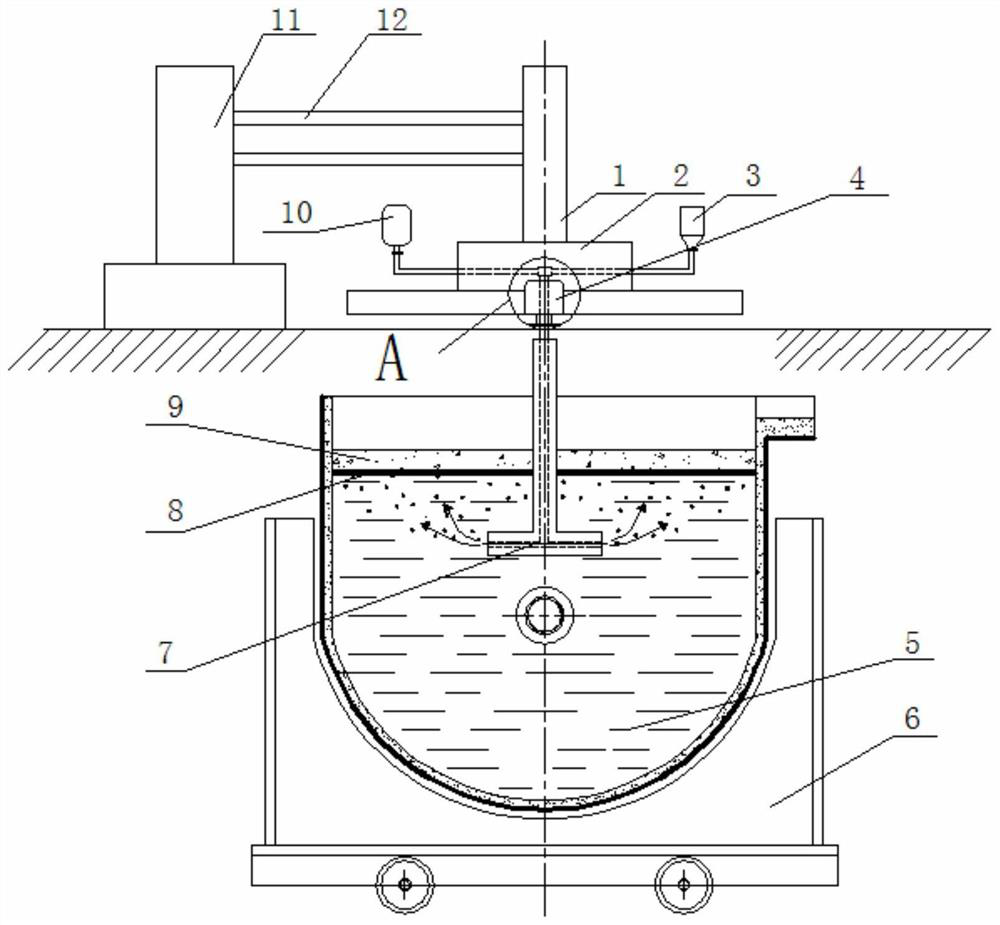

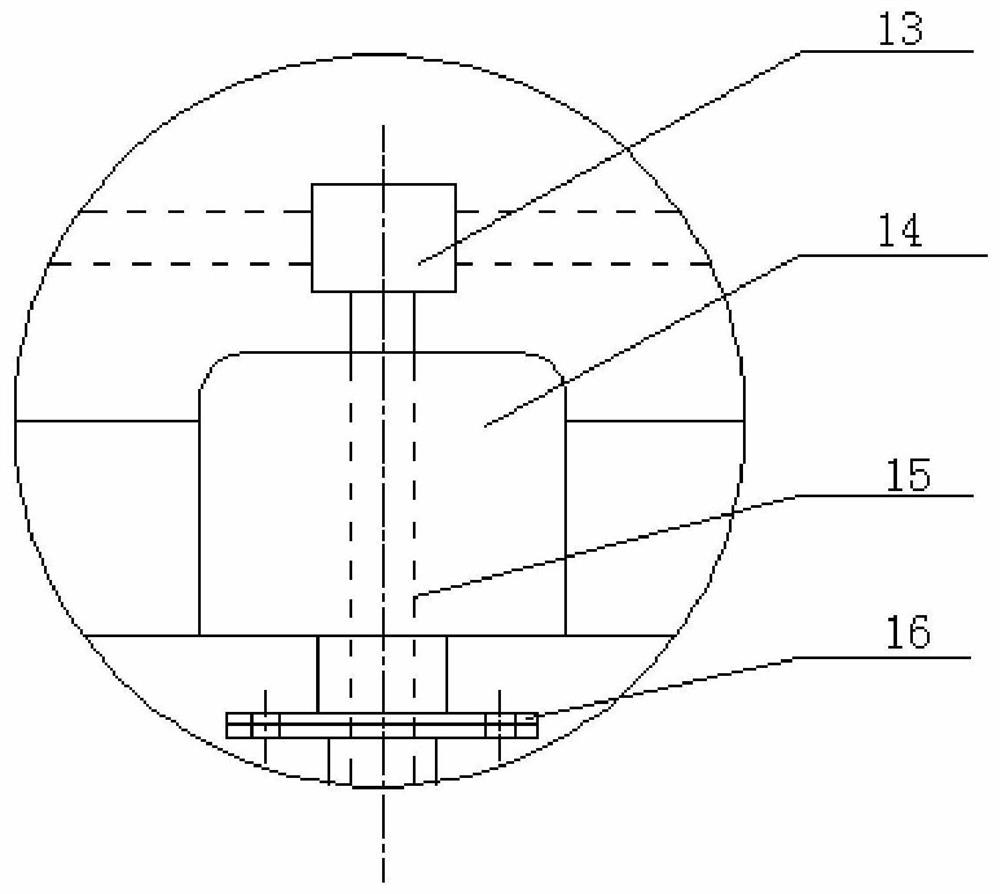

[0022] Such as figure 1 , 2 As shown, a rotating powder spraying device for ladle slag modification includes a lifting device, an anti-splash device 2, a feeding system 3, a blowing system 10, a rotating device 4, and a powder spraying gun 7. The powder spraying gun 7 is an inverted T-shaped hollow tube, with spray holes at both ends of the tube head, and refractory material wrapped on the outside; the rotary device 4 includes a rotary joint 13 and a motor 14 with a hollow shaft inside, and the rotary joint 13 is a three-way pipe as a whole structure, the internal bearing is connected to the upper end of the hollow shaft 15 in the motor, the rotary joint 13 is connected to the pipeline in the horizontal direction, and the lower end of the hollow shaft 15 is connected to the upper end of the powder spray gun 7 through the flange 16; the splash prevention device 2 is an upper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com