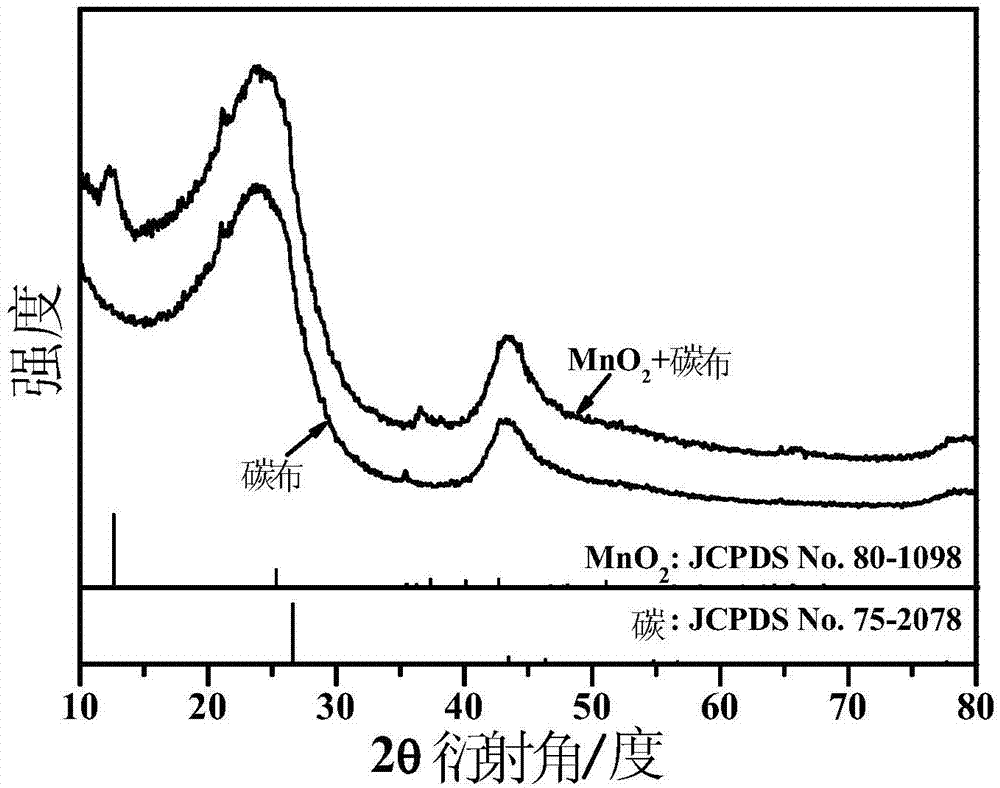

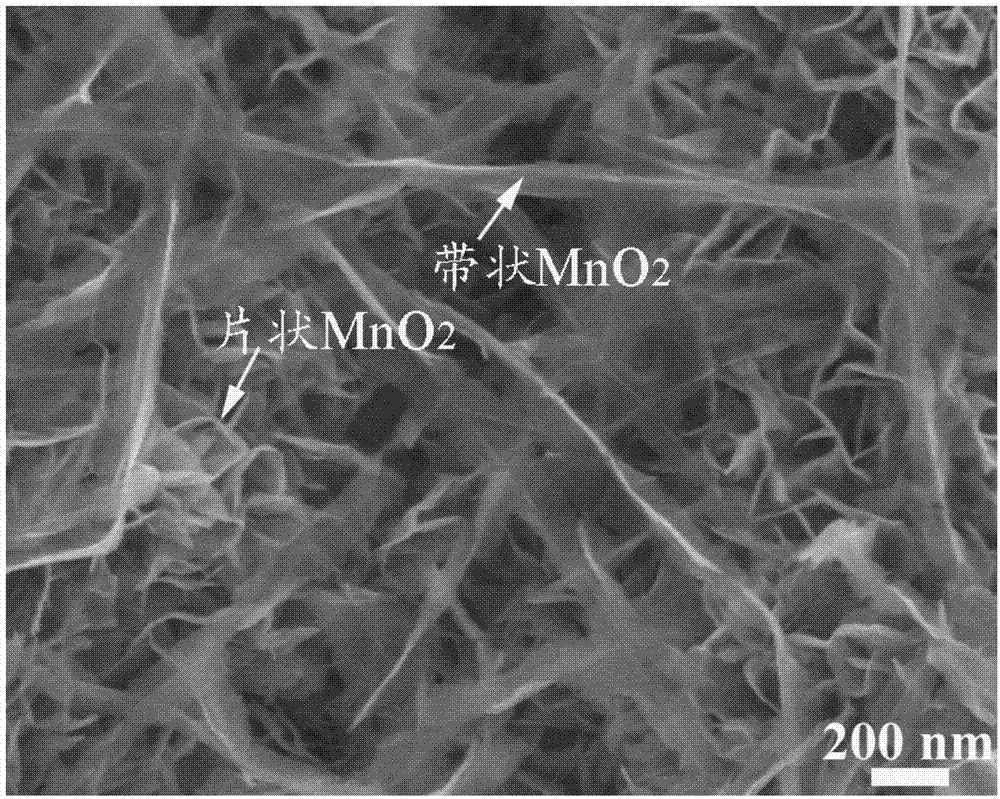

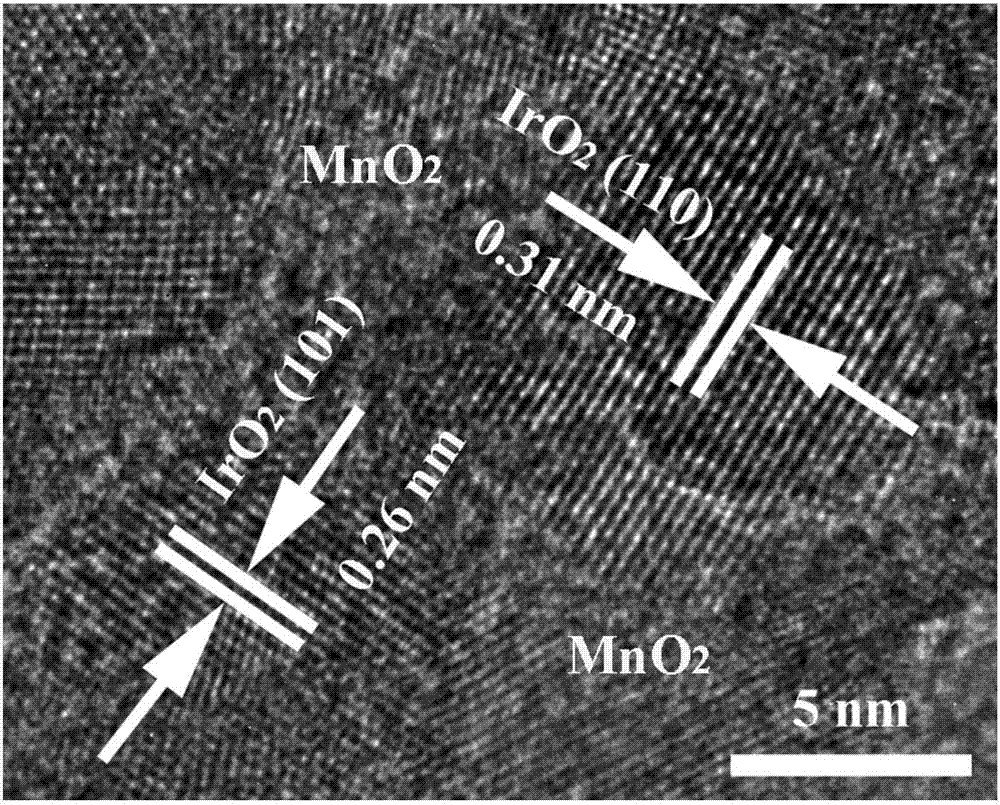

Iridic oxide/manganese dioxide combined electrode with hierarchical structure and preparation method thereof

A composite electrode and hierarchical structure technology, which is applied to fuel cell type half cells and primary cell type half cells, battery electrodes, structural parts, etc., to achieve the effect of reducing overpotential and improving catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] After the commercial carbon cloth was hydrothermally reacted in 69wt% concentrated nitric acid at 90°C for 2 hours, it was first washed with deionized water, then ultrasonically cleaned with acetone, alcohol, and deionized water for 15 minutes, and then heated in air at 60°C. Dry for 8h; KMnO 4 Dissolve in deionized water and stir well to obtain K + A solution with a concentration of 0.0005mol / L, the above-mentioned pretreated commercial carbon cloth was immersed in the solution for 2 hours, and then hydrothermally reacted at 85°C for 2.5h, then washed with deionized water, and dried at 60°C in the air for 8 hours to obtain commercial Manganese-containing precursor supported on carbon cloth; KMnO 4 and IrCl 3 Dissolve in deionized water and stir evenly to obtain K + and Ir 3+ The concentrations were 0.001 mol / L and 0.00025 mol / L mixed solution respectively. The above-mentioned dried commercial carbon cloth loaded with manganese precursor was immersed in the mixed so...

Embodiment 2

[0071] After the commercial carbon felt was hydrothermally reacted in 69wt% concentrated nitric acid at 90°C for 2 hours, it was first washed with deionized water, then ultrasonically cleaned with acetone, alcohol, and deionized water for 15 minutes, and then heated in air at 60°C. Dry for 8h; KMnO 4 Dissolve in deionized water and stir well to obtain K + A solution with a concentration of 0.0003 mol / L, soak the pretreated carbon felt in the solution for 2 hours, and then conduct a hydrothermal reaction at 70°C for 1 hour, then wash with deionized water, and dry at 60°C in the air for 8 hours to obtain a carbon felt load. The manganese-containing precursor; the KMnO 4 and IrCl 3 Dissolve in deionized water and stir evenly to obtain K + and Ir 3+ The concentration is 0.0008mol / L and 0.0003mol / L mixed solution respectively, the above-mentioned dried carbon felt loaded with manganese precursor is immersed in the mixed solution for 2h, then hydrothermally reacted at 70℃ for 2h...

Embodiment 3

[0075] After the commercial carbon cloth was hydrothermally reacted in 69wt% concentrated nitric acid at 90°C for 2 hours, it was first washed with deionized water, then ultrasonically cleaned with acetone, alcohol, and deionized water for 15 minutes, and then heated in air at 60°C. Dry for 8h; KMnO 4 Dissolve in deionized water and stir well to obtain K + A solution with a concentration of 0.001mol / L, the above pretreated commercial carbon cloth was immersed in the solution for 2 hours, then hydrothermally reacted at 90°C for 3h, then washed with deionized water, and dried at 60°C in the air for 8h to obtain commercial carbon cloth Fabric-loaded manganese-containing precursor; the KMnO 4 and IrCl 3 Dissolve in deionized water and stir evenly to obtain K + and Ir 3+ The concentrations were 0.0015 mol / L and 0.0002 mol / L mixed solution respectively, the above-mentioned dried commercial carbon cloth loaded with manganese precursor was immersed in the mixed solution for 2 h, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com