Warming heating bag

A technology of heating packs and raw materials, which is applied in the directions of heat exchange materials, heating appliances for treatment and cooling appliances for treatment, etc. The effect of good use effect, prevention of excessive temperature and high utilization rate of heat production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

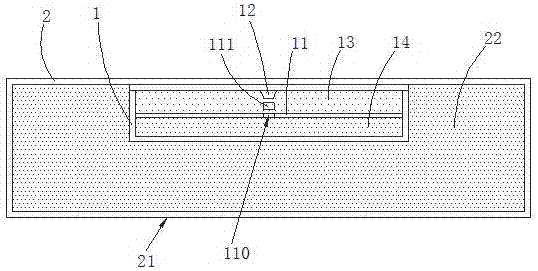

[0015] refer to figure 1 , The heating pack of this embodiment is composed of an inner bag 1 and an outer bag 2, the inner bag 1 is buried in the outer bag 2; the inner bag 1 is distributed away from the heat compress surface 21 of the outer bag 2, and both the inner bag 1 and the outer bag 2 are made of sealed and waterproof materials. The inner bag 1 is equipped with 4.5 parts of water and 14 parts of quicklime that are sealed and separated by the pierceable separation layer 11; the center of the separation layer 11 is equipped with a water leakage hole 110 and a matching sealing plug 111, and the inner bag 1 is fixed and installed. Used to push the sealing plug 111 out of the boss 12 of the leakage hole 110; as figure 1 As shown, the water layer 13 is arranged above the separation layer 11, and the quicklime layer 14 is arranged below the separation layer 11; the water layer 13 gradually flows into the lime layer 14 from the water leakage hole 110, and the preferred flow ra...

Embodiment approach 2

[0017] refer to figure 1 , The heating pack of this embodiment is composed of an inner bag 1 and an outer bag 2, the inner bag 1 is buried in the outer bag 2; the inner bag 1 is distributed away from the heat compress surface 21 of the outer bag 2, and both the inner bag 1 and the outer bag 2 are made of sealed and waterproof materials. The inner bag 1 is equipped with 5 parts of water and 15 parts of quicklime that are sealed and separated by a pierceable separation layer 11; the center of the separation layer 11 is equipped with a water leakage hole 110 and a matching sealing plug 111, and the inner bag 1 is fixed and installed. Used to push the sealing plug 111 out of the boss 12 of the leakage hole 110; as figure 1 As shown, the water layer 13 is arranged above the separation layer 11, and the quicklime layer 14 is arranged below the separation layer 11; the water layer 13 gradually flows into the lime layer 14 from the water leakage hole 110, and the preferred flow rate i...

Embodiment approach 3

[0019] refer to figure 1 , The heating pack of this embodiment is composed of an inner bag 1 and an outer bag 2, the inner bag 1 is buried in the outer bag 2; the inner bag 1 is distributed away from the heat compress surface 21 of the outer bag 2, and both the inner bag 1 and the outer bag 2 are made of sealed and waterproof materials. The inner bag 1 is equipped with 4 parts of water and 12 parts of quicklime that are sealed and separated by a pierceable separation layer 11; the center of the separation layer 11 is equipped with a water leakage hole 110 and a matching sealing plug 111, and the inner bag 1 is fixed and installed. Used to push the sealing plug 111 out of the boss 12 of the leakage hole 110; as figure 1 As shown, the water layer 13 is arranged above the separation layer 11, and the quicklime layer 14 is arranged below the separation layer 11; the water layer 13 gradually flows into the lime layer 14 from the water leakage hole 110, and the preferred flow rate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com