A kind of method that microchannel reactor prepares chlorenyne

A microchannel reactor, chloroenyne technology, applied in chemical instruments and methods, chemical/physics/physicochemical reactors, preparation of carboxylic acid halides, etc. There are hidden dangers in production safety, and the appearance of products is prone to yellowing, etc., to avoid explosive accidents, reduce the generation of by-products, and have a large heat exchange contact surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

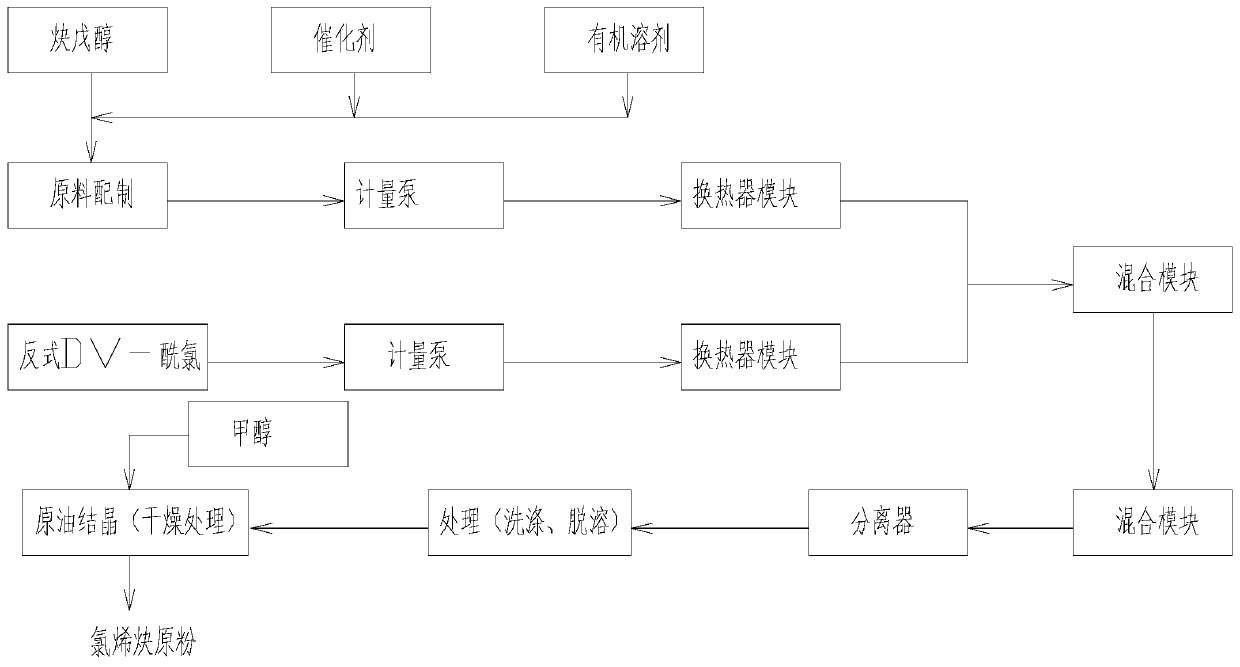

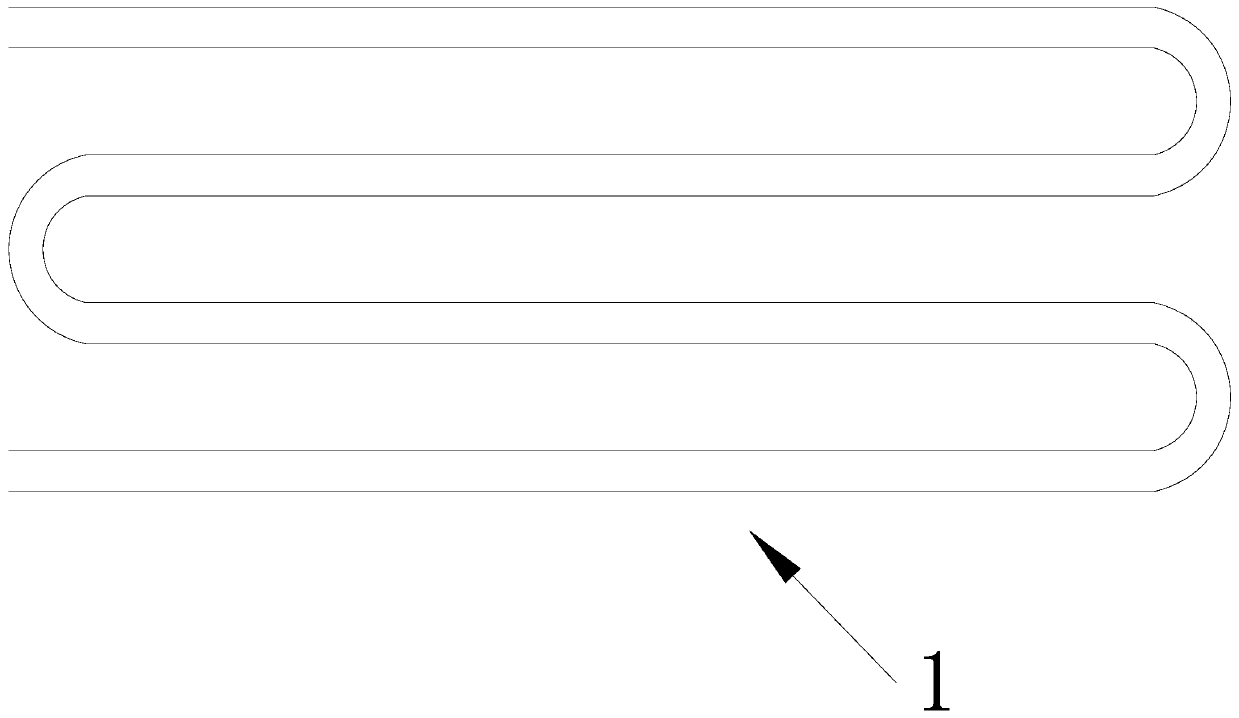

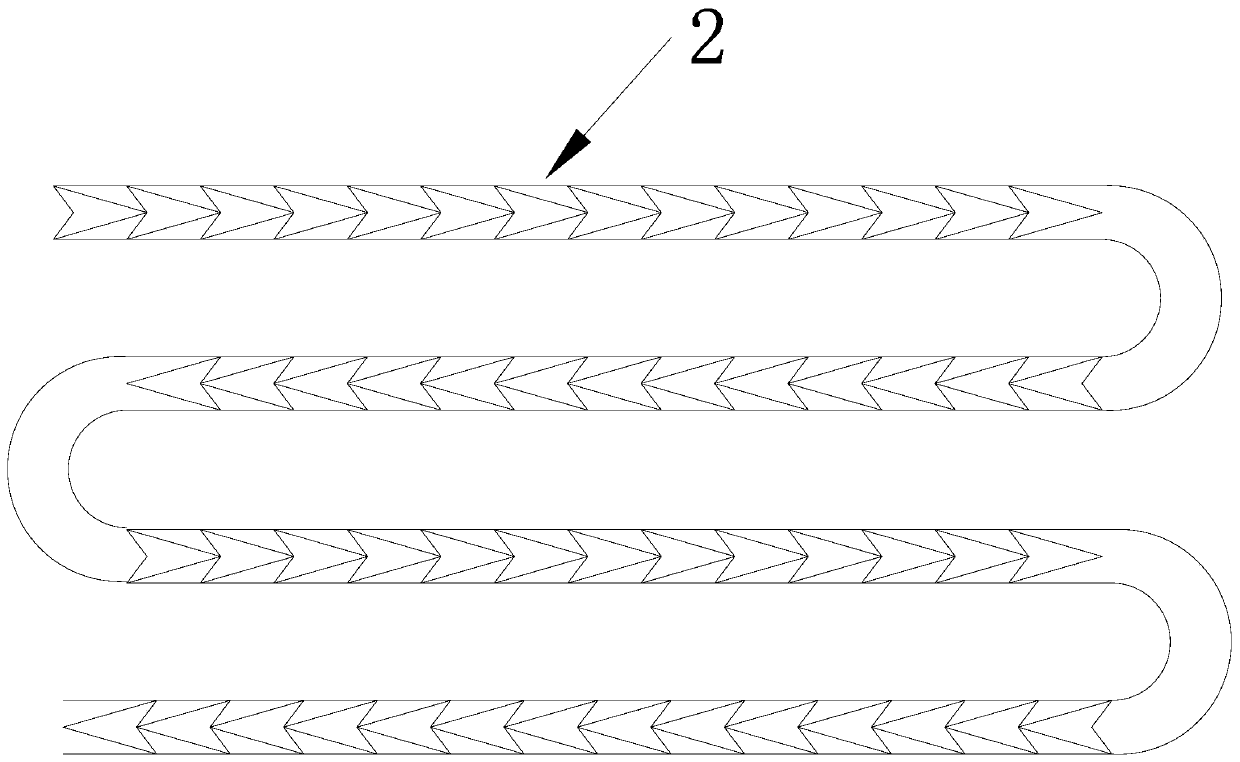

[0042] A microchannel reactor (direct current channel module + V-shaped structure module, module material 316 stainless steel) is used, connected according to the drawings in the manual, the number of modules is determined according to the flow rate and reaction residence time, the material is injected into the heat exchange module through a metering pump, and the heat exchange is performed. The medium is heat transfer oil.

[0043] (1) Prepare a mixed solution of pentynyl alcohol and diisopropylamine, mix the pentynyl alcohol and diisopropylamine in toluene, and store them in the raw material tank for later use. The molar ratio of the materials is pentynyl alcohol:diisopropylamine:toluene=1: 0.0001:2.

[0044](2) After the prepared mixed solution enters the heat exchange module with a metering pump for heat exchange, it will be mixed and reacted synchronously with the trans-DV-chrysanthemum acid chloride after entering the heat exchange module 1 through the metering pump in t...

Embodiment 2

[0049] A microchannel reactor (direct current channel module + cone trapezoidal structure module, module material PEEK) is used, connected according to the drawings in the manual, the number of modules is determined according to the flow rate and reaction residence time, the material is injected into the heat exchange module through a metering pump, and the heat exchange medium For heat transfer oil.

[0050] (1) Prepare a mixture of pentynyl alcohol and tetramethylguanidine, mix the pentynyl alcohol and tetramethylguanidine in dichloroethane, store it in a raw material tank for later use, and the molar ratio of the materials is pentynyl alcohol:tetramethylguanidine Guanidine: dichloroethane = 1:0.0005:4.

[0051] (2) After the prepared mixed solution enters the heat exchange module with a metering pump for heat exchange, it is mixed and reacted synchronously with the trans-DV-chrysanthemum acid chloride after entering the heat exchange module through the metering pump, and th...

Embodiment 3

[0056] A microchannel reactor (direct current channel module + cone-trapezoidal structure module, module material Hastelloy alloy) is used, connected according to the drawings in the manual, the number of modules is determined according to the flow rate and reaction residence time, and the material is pumped into the heat exchange module through a metering pump. The heat medium is water.

[0057] (1) Prepare a mixed solution of pentynyl alcohol and diisopropylamine, mix the pentynyl alcohol and diisopropylamine in chloroform, and store them in a raw material tank for later use. The molar ratio of the materials is pentynyl alcohol: diisopropylamine: chloroform =1:0.001:3.

[0058] (2) After the prepared mixed solution enters the heat exchange module with a metering pump for heat exchange, it will react synchronously with the DV-chrysanthemum acid chloride after entering the heat exchange module through the metering pump in the mixing module. The mixing reaction temperature is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com