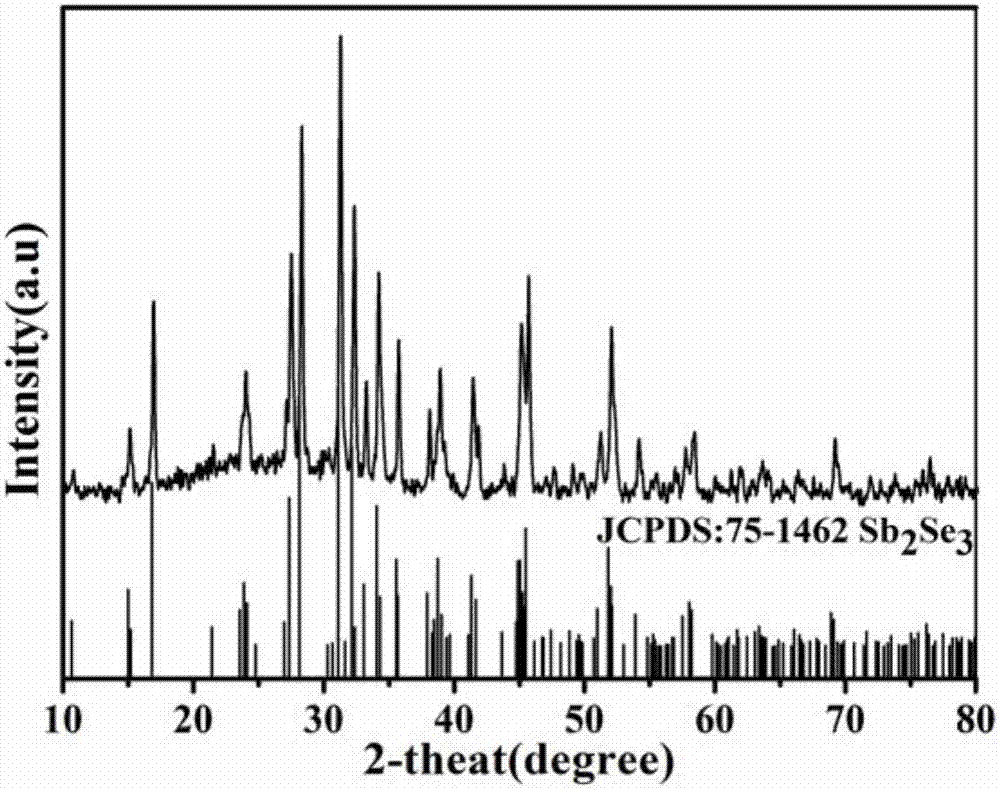

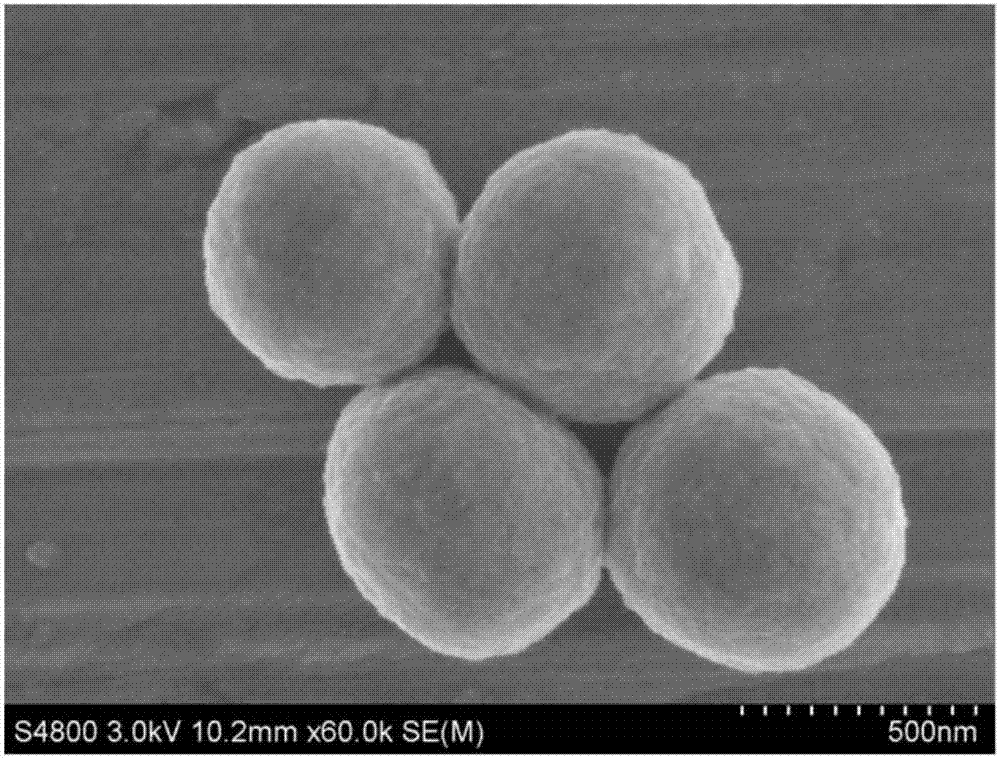

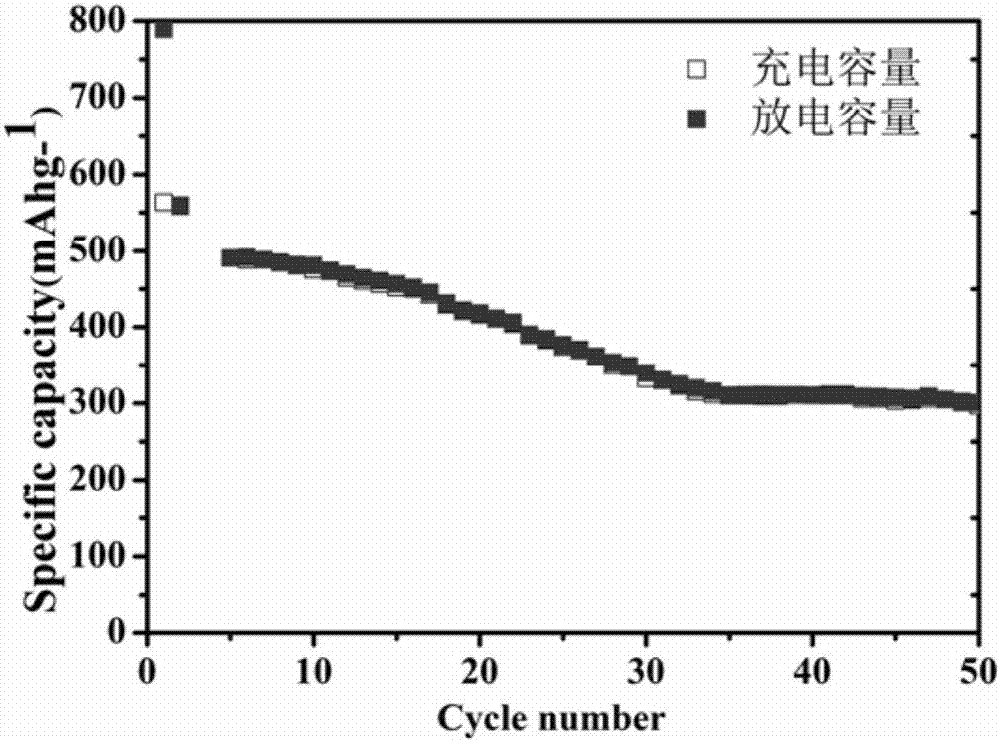

Method for hydrothermally and simply preparing spherical antimony selenide sodium ion battery cathode

A technology of sodium antimony selenide and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., to achieve good cycle performance, simple equipment, and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Add 0.0351g of antimony potassium tartrate, 0.0192g of citric acid and 0.03g of polyvinylpyrrolidone into 80mL of distilled water, and ultrasonically shake (200W, 40°C, 10min) to completely dissolve and disperse evenly to obtain solution A; among them, polyethylene The average molecular weight of pyrrolidone is 30000;

[0026] 2) Disperse selenium powder and sodium borohydride in distilled water, and ultrasonically oscillate (500W, 40°C, 10min) to dissolve it completely to obtain a transparent solution B, wherein the ratio of the amount of selenium powder to sodium borohydride is 0.156: 0.156, the concentration of sodium borohydride is 0.078mol / L, and the total volume of transparent solution B is 2mL;

[0027] 3) The obtained solution B was added dropwise to the solution A under the condition of stirring (500r / min, 30min) to obtain the mixed solution C;

[0028] 4) Firstly, put the mixed solution C into a polytetrafluoroethylene hydrothermal liner and put it into a ho...

Embodiment 2

[0030] 1) Add 0.1322g of antimony potassium tartrate, 0.0384g of citric acid and 0.1g of polyvinylpyrrolidone into 70mL of distilled water, and ultrasonically shake (300W, 50°C, 20min) to completely dissolve and disperse evenly to obtain solution A; among them, polyethylene The average molecular weight of pyrrolidone is 30000;

[0031] 2) Disperse selenium powder and sodium borohydride in distilled water, and ultrasonically oscillate (600W, 50°C, 20min) to dissolve it completely to obtain a transparent solution B, wherein the ratio of the amount of selenium powder to sodium borohydride is 0.525: 0.63, the concentration of sodium borohydride is 0.1575mol / L, and the total volume of solution B is 4mL;

[0032] 3) The obtained solution B was added dropwise to the solution A under the condition of stirring (500r / min, 20min) to obtain the mixed solution C;

[0033] 4) First, put the mixed solution C into a polytetrafluoroethylene hydrothermal liner and put it into a homogeneous rea...

Embodiment 3

[0035] 1) Add 0.3379g of antimony potassium tartrate, 0.0769g of citric acid and 0.15g of polyvinylpyrrolidone into 70mL of distilled water, and ultrasonically shake (400W, 40°C, 30min) to completely dissolve and disperse evenly to obtain solution A; among them, polyethylene The average molecular weight of pyrrolidone is 30000;

[0036] 2) Disperse selenium powder and sodium borohydride in distilled water, and ultrasonically oscillate (400W, 70°C, 10min) to dissolve it completely to obtain a transparent solution B, wherein the ratio of the amount of selenium powder to sodium borohydride is 1.47: 1.911, the concentration of sodium borohydride is 0.3822mol / L, and the total volume of solution B is 5mL;

[0037] 3) The obtained solution B was added dropwise to the solution A under the condition of stirring (600r / min, 40min) to obtain the mixed solution C;

[0038] 4) First, put the mixed solution C into a polytetrafluoroethylene hydrothermal liner and put it into a homogeneous re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com