Meerschaum-hydroxyl oxidize iron-active carbon composite adsorbent preparation method and application thereof

A sepiolite hydroxyl and composite adsorption technology, which is applied in adsorption water/sewage treatment, other chemical processes, chemical instruments and methods, etc., can solve problems such as poor ion effect, and achieve easy preservation, simple regeneration conditions and low investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

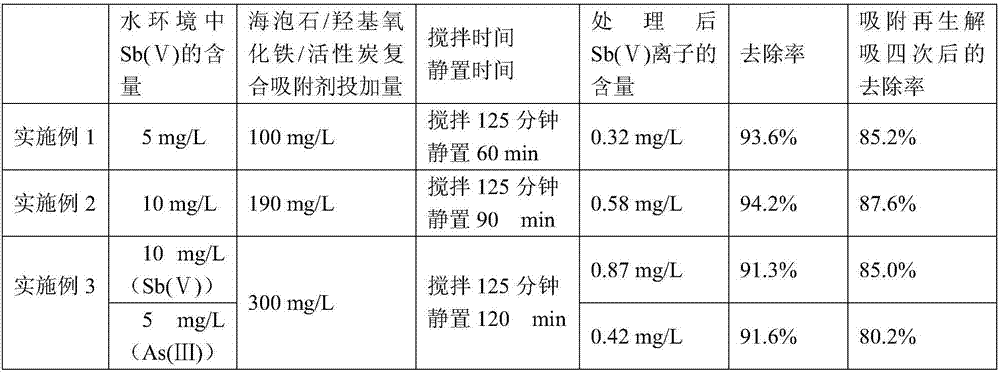

Examples

Embodiment 1

[0022] (1) Take 100 parts by weight of dry wheat straw, after crushing, pulverizing with a superfine pulverizer and refining with a superfine pulverizer, to obtain a powder particle A with a particle size of 200 meshes;

[0023] (2) Take 10 parts by weight of purified sepiolite with a particle size of 100 mesh, put it into a sulfuric acid solution with a concentration of 2mol / L, and stir continuously for 3 hours under the condition of a constant temperature water bath at 40°C. The solid-to-liquid ratio is 1:30. Separation by filtration, repeated washing with deionized water and absolute ethanol until the aqueous solution is neutral, drying at 65°C to obtain powder B, ready for use;

[0024] (3) Using sepiolite powder B, sodium alginate and water as raw materials, prepare a mixed solution C at a mass ratio of 1:3:2, and after fully stirring, put the mixed solution C into the reactor for hydrothermal carbonization reaction 6h, the hydrothermal carbonization reaction temperature ...

Embodiment 2

[0032] (1) Get the humic activated sludge of 150 weight parts, after crushing, pulverizing by ultrafine pulverizer and refinement by ultrafine pulverizer, the obtained particle size is 100 mesh powder particles A;

[0033] (2) Get 10 parts by weight of purified sepiolite with a particle size of 120 mesh, put it into a sulfuric acid solution with a concentration of 2.5mol / L and continuously stir for 3 hours under the condition of a constant temperature water bath at 50°C, the solid-to-liquid ratio is 1:40, Separation by suction filtration, repeated washing with deionized water and absolute ethanol until the aqueous solution is neutral, drying at 65°C to obtain powder B, ready for use;

[0034] (3) Using sepiolite powder B, sodium alginate and water as raw materials, prepare a mixed solution C at a mass ratio of 1:2:2, and after fully stirring, put the mixed solution C into the reactor for hydrothermal carbonization reaction For 8 hours, the temperature of the hydrothermal carbo...

Embodiment 3

[0042] (1) Get 150 parts by weight of rice husks, after crushing, pulverizing with a superfine pulverizer and refinement with a superfine pulverizer, to obtain a powder particle A with a particle size of 100 mesh;

[0043] (2) Get 10 parts by weight of purified sepiolite with a particle size of 100 mesh, put it into a sulfuric acid solution with a concentration of 2.0mol / L, and stir continuously for 3 hours under the condition of a constant temperature water bath at 50°C, the solid-to-liquid ratio is 1:30, Separation by suction filtration, repeated washing with deionized water and absolute ethanol until the aqueous solution is neutral, drying at 60°C to obtain powder B, ready for use;

[0044] (3) Using sepiolite powder B, sodium alginate and water as raw materials, prepare a mixed solution C at a mass ratio of 1:2:2, and after fully stirring, put the mixed solution C into the reactor for hydrothermal carbonization reaction For 8 hours, the temperature of the hydrothermal carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com