Catalyst for preparation of 2,6-dimethylnaphthalene as well as preparation and application of catalyst

A dimethylnaphthalene catalyst, a catalyst technology, applied in the directions of catalysts, molecular sieve catalysts, carbon compound catalysts, etc., can solve the problem that the catalyst cannot be high at the same time, and achieve the effects of improving accessibility, improving catalytic performance, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Preparation of seed solution

[0024] Combine 14.57g pseudo-boehmite (70%), 18.43g phosphoric acid (85%), 11.13g di-n-propylamine (DPA) and 60.55g water in a molar ratio of 1.1DPA: 1.0Al 2 O 3 :0.8P 2 O 5 :40H 2 The initial gel mixture was prepared by O, and hydrothermally crystallized at 100°C for 24 hours to obtain AlPO-11 seed solution A.

Embodiment 2

[0025] Example 2: Preparation of seed solution

[0026] Combine 14.57g pseudo-boehmite (70%), 27.65g phosphoric acid (85%), 11.13g diisopropylamine (DIPA) and 42.55g water according to the molar ratio of 1.0DIPA: 1.0Al 2 O 3 : 1.2P 2 O 5 :30H 2 O prepares the initial gel mixture and hydrothermally crystallizes it at 180°C for 12 hours to obtain AlPO-11 seed solution B.

Embodiment 3

[0027] Example 3: Catalyst preparation

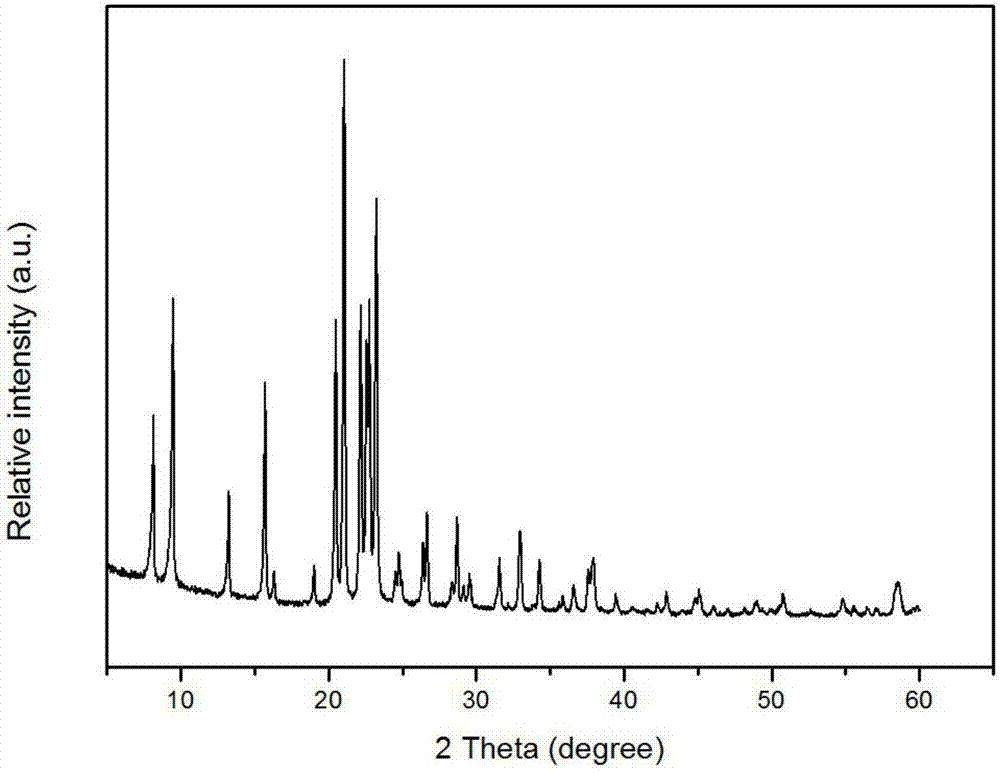

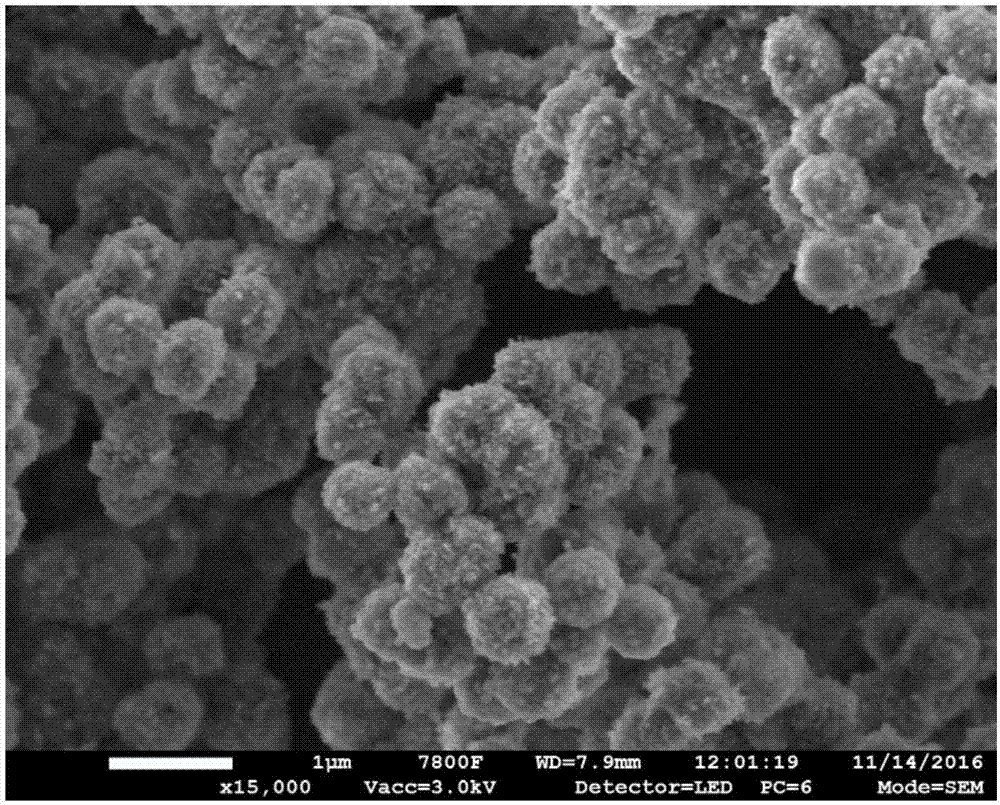

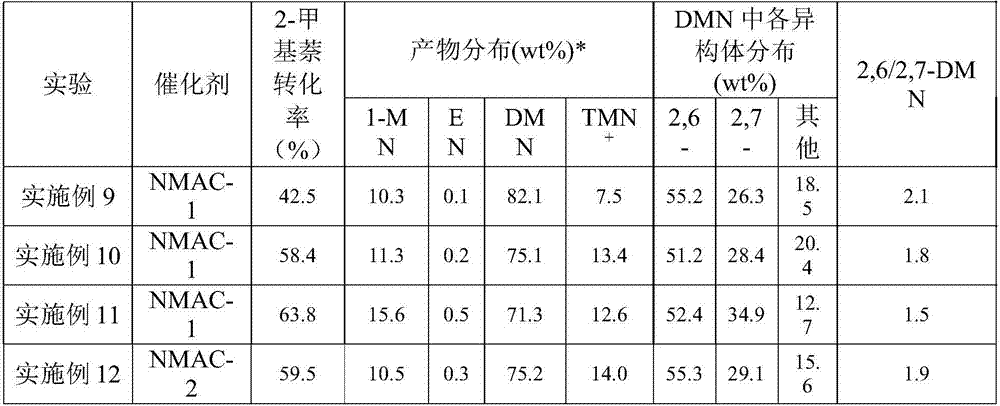

[0028] 0.017g cerium oxide, 14.57g pseudo-boehmite (70%), 18.43g phosphoric acid (85%), 0.2g silica sol (30%), 12.14g di-n-propylamine (DPA), 0.51g F-127( The molecular weight is 12600) and 42.55g water is 1.2DPA: 0.001CeO in molar ratio 2 : 1.0Al 2 O 3 :0.8P 2 O 5 :0.01SiO 2 :30H 2 O prepare the initial gel mixture, mix well, add 2.09g seed solution A, stir the mixture evenly and dry, grind to obtain the dry glue fine powder, then place it on the support inside the stainless steel reactor, add 5ml to the bottom of the reactor Water and 5ml of di-n-propylamine, the liquid surface cannot be in contact with the dry glue, crystallize at 200°C for 24 hours, wash, dry, and roast to obtain a sponge-like porous structure CeAPSO-11 molecular sieve, labeled as NMAC-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com